We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

What is the key role of Wheel Hub Motorcycle Casting Mold in motorcycle manufacturing?

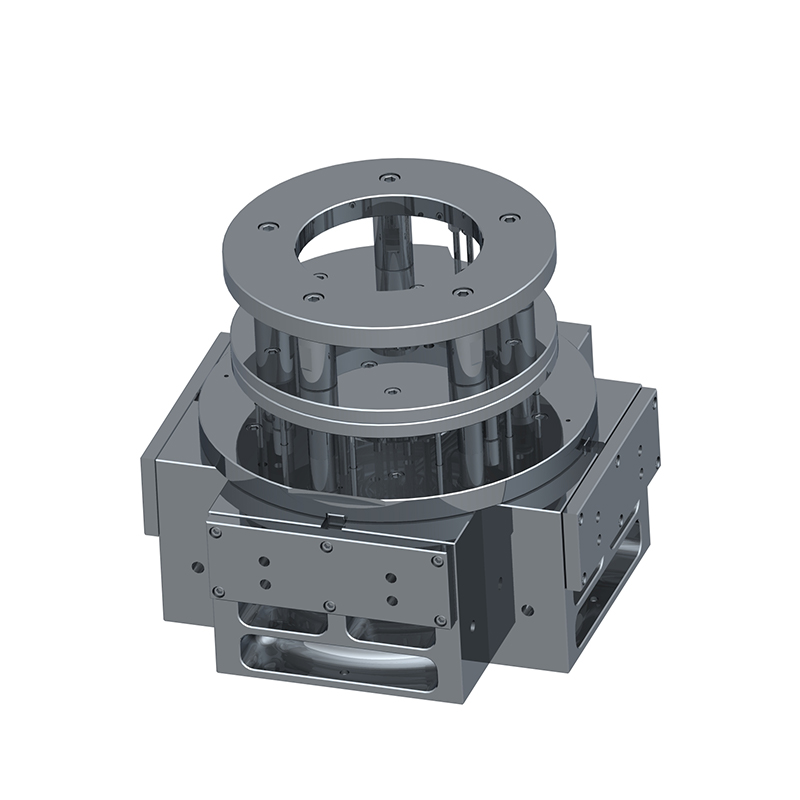

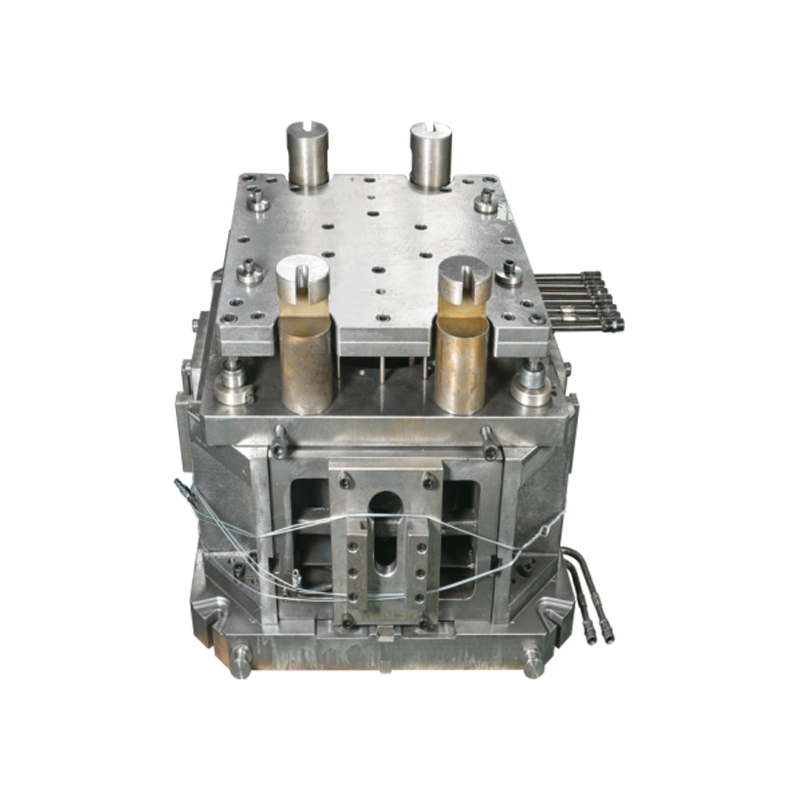

Wheel Hub Motorcycle Casting Mold plays a vital role in the motorcycle manufacturing process. Its advantages are not only reflected in improving production efficiency and reducing costs, but also greatly improving product quality, enhancing design flexibility, and providing support in terms of durability, reliability, etc. Using Wheel Hub Motorcycle Casting Mold can significantly improve production efficiency. The production of motorcycle wheels usually requires precise size and shape requirements. Manual production or traditional processing methods often cannot achieve consistency, while casting molds can accurately replicate every detail. By using casting molds, motorcycle manufacturers can achieve mass production, and the accuracy of each product can be guaranteed, thereby reducing errors in the production process. At the same time, the use of molds makes the production process more automated and reduces the need for manual intervention, which significantly improves production speed. With the optimization of manufacturing processes, motorcycle wheels can be cast and put on the market faster to meet the ever-changing consumer needs.

In addition to improving production efficiency, Wheel Hub Motorcycle Casting Mold can also significantly improve product quality. Casting molds play a vital role in production because they ensure that every detail of each wheel is completed according to strict standards. Through precise mold design, common defects in the casting process, such as pores, cracks or surface unevenness, can be avoided. The high precision of the casting mold ensures that the size, shape and strength of the motorcycle wheel hub are consistent, thereby improving the overall quality. For motorcycle manufacturers, wheels produced using high-quality molds can better meet consumer requirements for safety and reliability, and reduce the risk of product repairs and quality complaints.

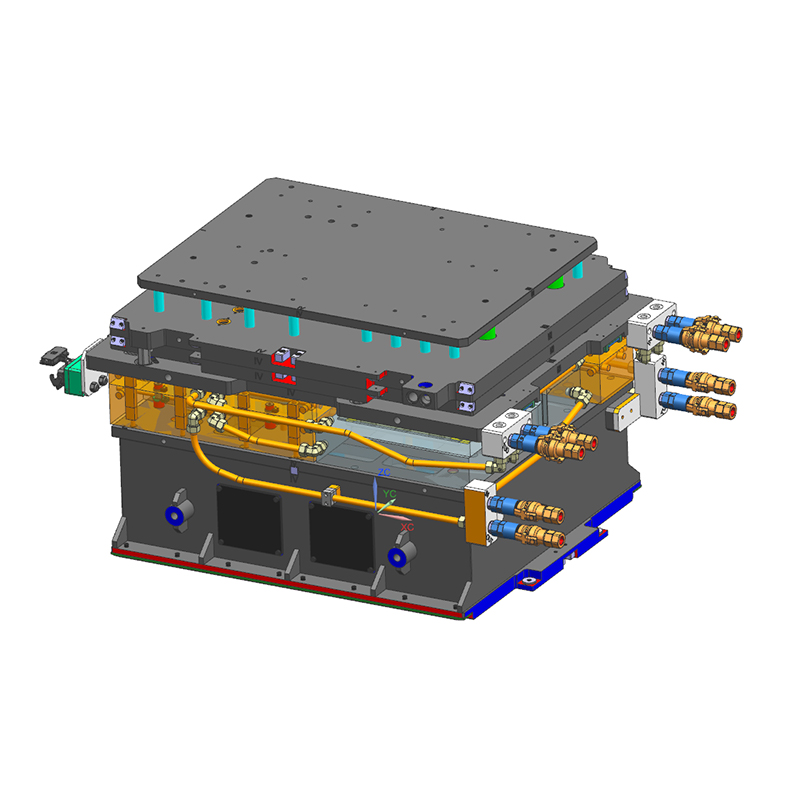

The production cost of motorcycle wheels has always been a focus of manufacturers. Although the initial investment in casting molds is high, in the long run, the use of Wheel Hub Motorcycle Casting Mold can greatly reduce the production cost of a single wheel hub. Through the precise mold casting process, efficient production can be achieved, raw material waste can be reduced, and material utilization can be optimized. At the same time, the reusability of the mold makes it almost unnecessary to readjust or reprocess during the production process, which greatly reduces downtime and human errors in the production process. With all these factors working together, motorcycle manufacturers can significantly reduce overall production costs while ensuring quality.

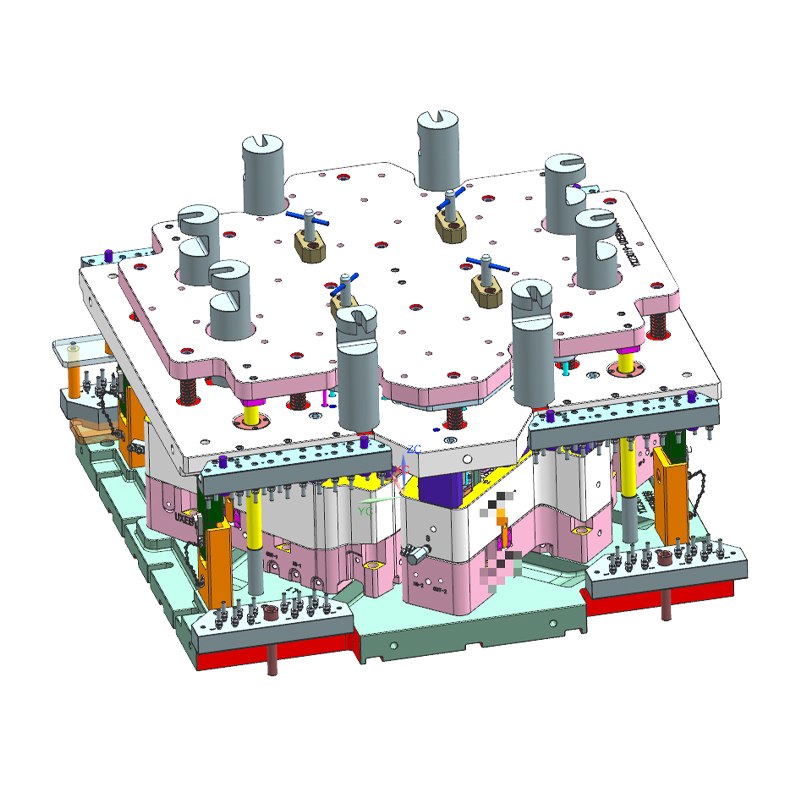

The use of Wheel Hub Motorcycle Casting Mold improves design flexibility. In modern motorcycle manufacturing, the design of the wheel hub must not only consider aesthetics, but also take into account lightweight, durability and performance. Casting molds provide designers with greater flexibility and freedom to support more complex and innovative designs. Designers can carefully design molds to produce wheels with special shapes or structures that meet market needs, thereby improving the appearance and performance of motorcycles. For example, the design of the mold can support elements such as fine curves, lightweight holes or reinforcing ribs, which may be difficult to achieve in traditional manufacturing processes. As the market demand for personalized and customized products increases, the design flexibility of molds brings more room for innovation for motorcycle manufacturers.

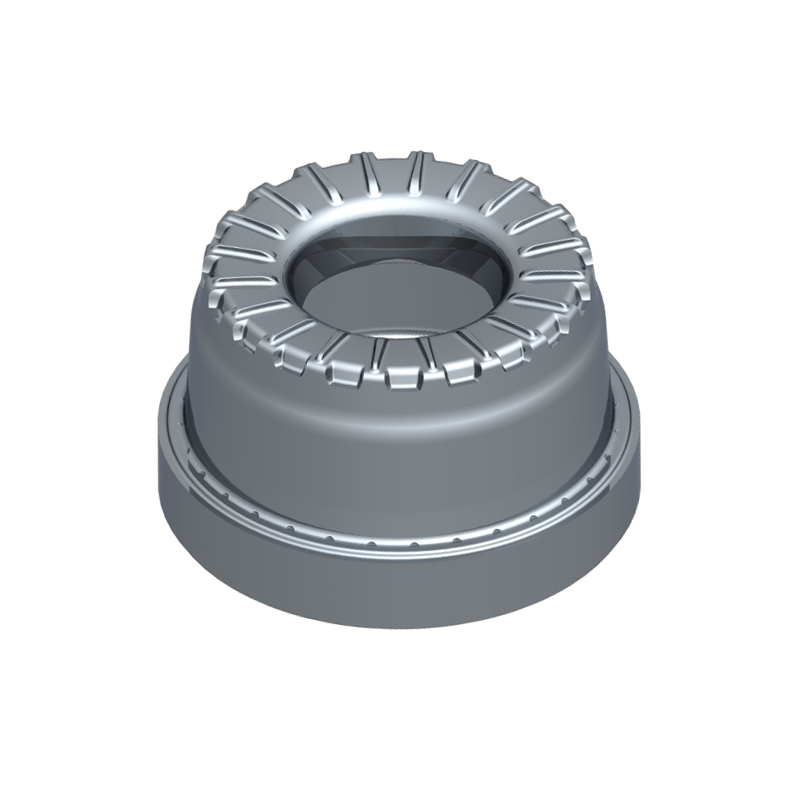

Durability and reliability are critical performance requirements for motorcycle wheels. The motorcycle wheel hub is the core component that carries the weight of the entire vehicle and must have sufficient strength and durability. Wheel Hub Motorcycle Casting Mold can ensure that the aluminum alloy or other high-strength materials used have good impact resistance, corrosion resistance and fatigue resistance during the manufacturing process. Through precise mold control and reasonable material selection, the cast motorcycle wheel hub can maintain long-term stable performance under harsh driving conditions. Whether it is high-speed driving, sharp turns or collisions, the reliability of the wheel hub is crucial. By using high-quality casting molds, motorcycle manufacturers are able to produce stronger and more durable wheels, improving the overall safety and riding experience of the motorcycle.

English

English 中文简体

中文简体