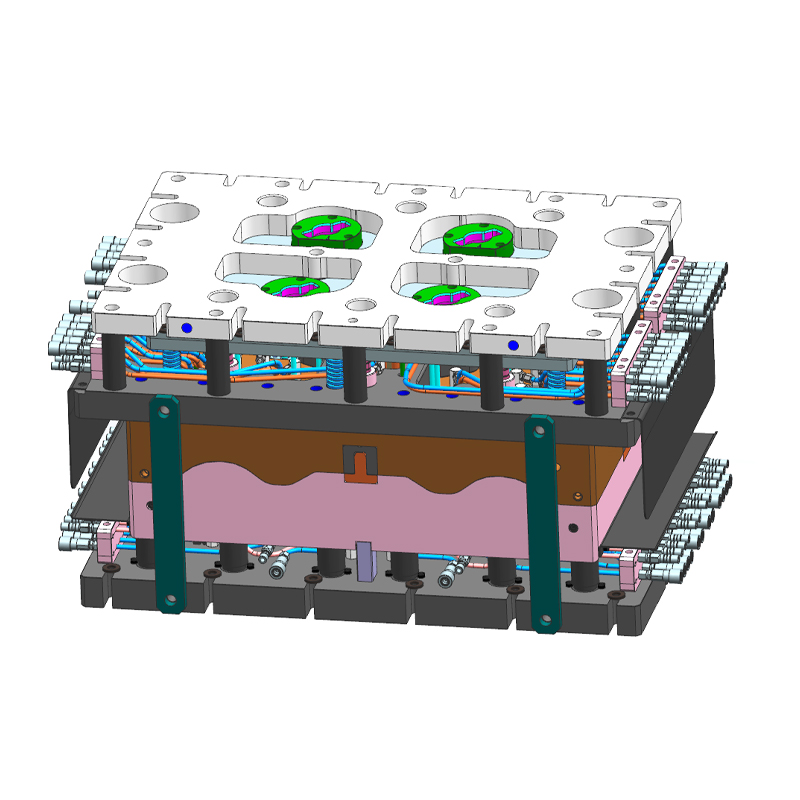

Precision plays a fundamental role in the production of wheel hub motorcycle casting molds. The wheel hub is a critical component of the motorcycle, responsible for supporting the wheel and ensuring s...

Casting Molds Suppliers

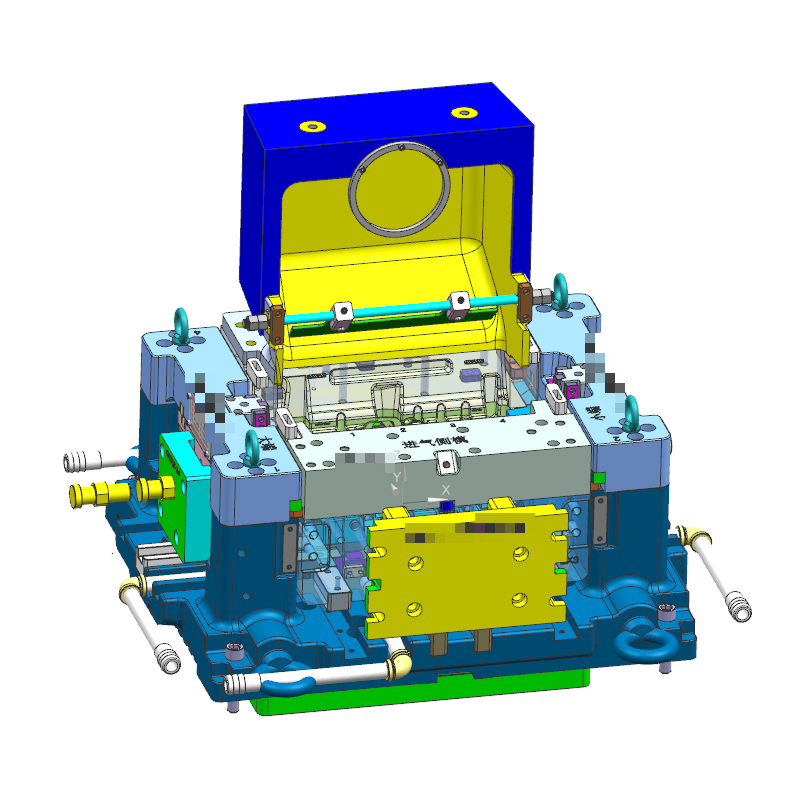

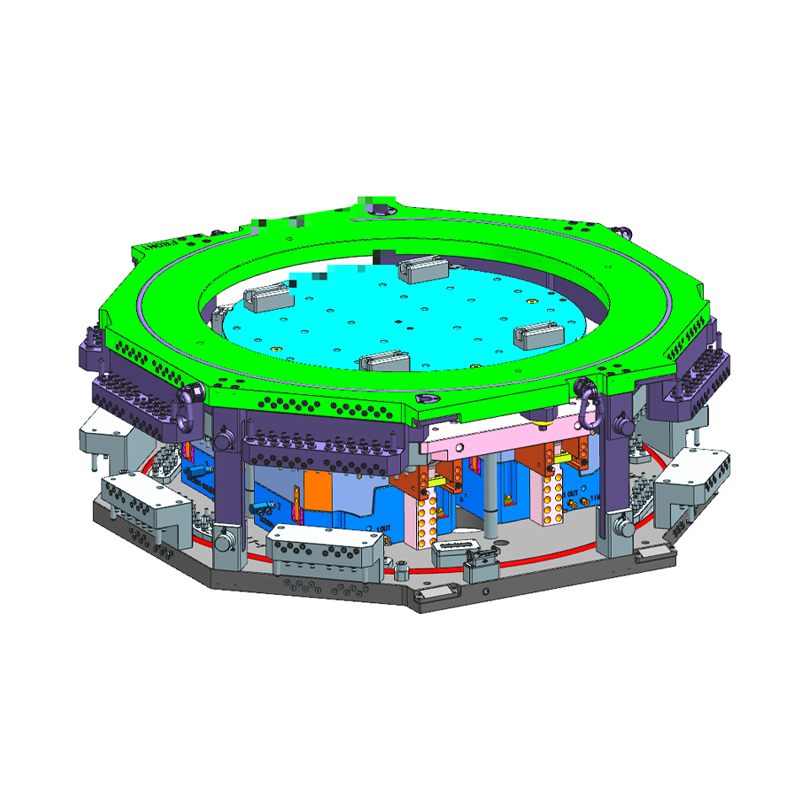

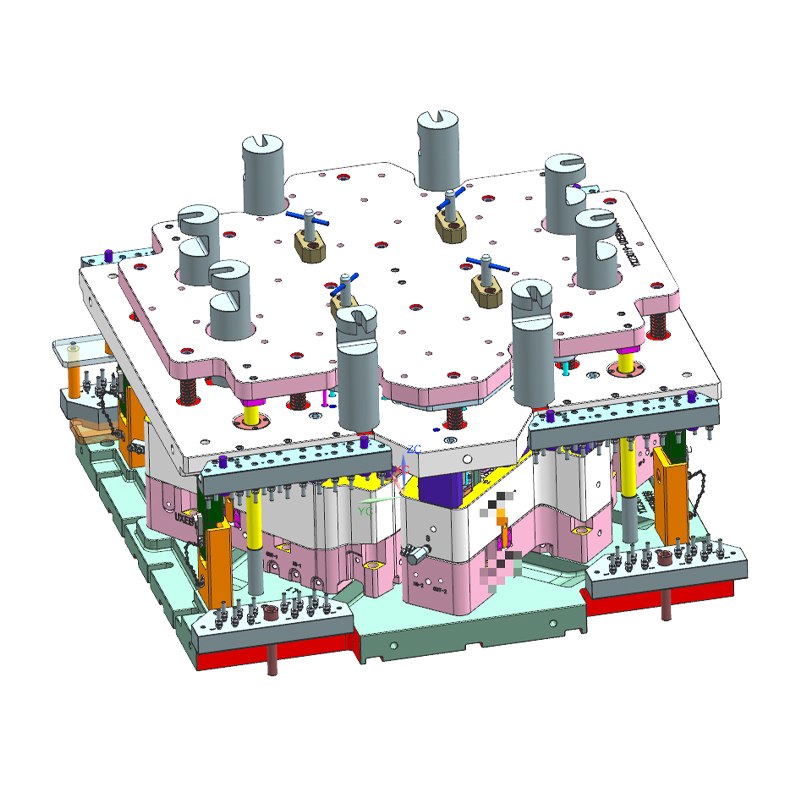

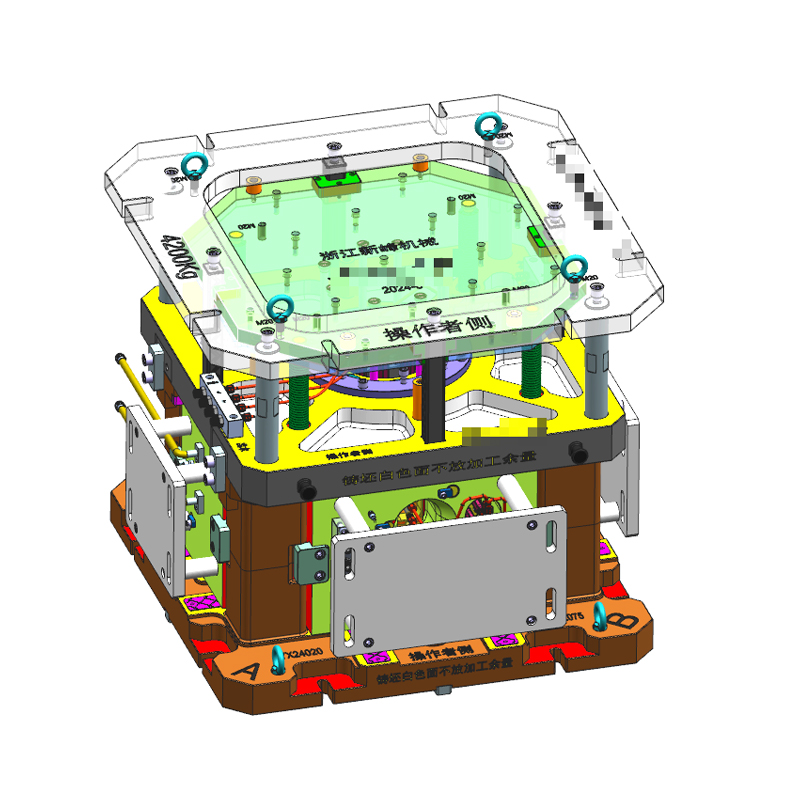

Our company provides diversified, high-quality casting molds, which are tailored for the molding needs of various materials such as metals,etc. We select superior materials, combine precision design with excellent durability, and carefully build each mold to ensure that all products meet the most stringent production standards. Whether it is small batch customization or large-scale production in pursuit of efficiency, our casting molds can respond flexibly and widely serve many industries such as automobile manufacturing, machinery industry, construction, and household appliances. These molds show excellent thermal stability, excellent corrosion resistance and ultra-long service life, which can help customers significantly improve production efficiency.

Zhejiang Xinfeng Machinery Co., Ltd. is professional China Casting Molds Suppliers and Custom Casting Molds Manufacturers.Zhejiang Xinfeng Machinery and Shengzhou Yuanfeng Mold are subsidiaries of Yongfeng Mold Group, with over 380 employees and annual sales of 550 million. Xinfeng specializes in aluminum wheel hub and structural casting molds, covering 30 acres, with a 16,000+ sqm plant, outputting 1,800 sets of molds annually, employing over 130 staff, including 30 skilled technicians and designers using CAD, UG, CATIA, etc. The company focuses on customer needs, innovation, and quality, implementing a mold production progress system and equipped with advanced machinery like CNC centers.

Yuanfeng Mold Co., Ltd. was established in Yongfeng Group, focusing on mold steel forging products, with multiple forging and electro slag remelting production lines, mainly producing mold raw materials such as H13 series and 35CrMo. The company actively promotes technological innovation and brand innovation, strengthens quality management, enhances corporate image, complies with ISO9001:2015 international quality system standards, and has won the titles of Shengzhou City's "30 Best" Enterprises, Integrity Enterprises, and National High-tech Enterprises.

Xinfeng Machinery actively participates in the "waste-free factory construction" and became a member of the "waste-free factory" in October 2022. It maintains long-term strategic cooperation with nearly 40 wheel hub factories and aluminum casting manufacturers, ranks among the top three in the aluminum alloy casting mold industry, leads the casting process industry, and produces 2,000 sets of molds annually. It is committed to using technology to improve product quality and using craftsmanship to create each product.

-

-

A wheel hub motorcycle casting mold is an essential tool in the manufacturing process of motorcycle wheel hubs. It plays a key role in shaping the molten metal into the precise dimensions required for...

-

A wheel hub differential pressure casting mold is a specialized mold used in the casting process to produce wheel hubs, commonly found in vehicles. The “differential pressure casting” technique involv...

1. How to improve product quality efficiently? Explore Zhejiang Xinfeng Machinery Co., Ltd.'s precision casting mold solutions!

In the pursuit of excellence in industrial manufacturing, every subtle improvement in product quality is crucial. When you face the challenge of producing high-quality, high-precision products, Zhejiang Xinfeng Machinery Co., Ltd. provides you with a comprehensive solution with its diverse casting mold technologies, including low-pressure casting molds, differential pressure casting molds and gravity casting molds. Low-pressure casting molds, with their unique low-pressure gas push method, ensure that the molten metal fills the mold evenly from the bottom to the top, effectively reducing the generation of oxidation and inclusions. It is particularly suitable for precision casting of low-melting-point metals such as aluminum alloys and magnesium alloys, such as the production of large and medium-sized thin-walled complex castings such as automobile wheels and engine blocks. This technology not only improves the appearance quality of the product, but also enhances its inherent performance, making your product more competitive in the market.

Xinfeng Machinery is well aware of the importance of technological innovation, and continuously introduces internationally advanced production equipment and technology, combines independent research and development, and continuously optimizes the casting process to ensure that each set of molds can accurately match customer needs and improve product consistency and stability. Choosing us is choosing a fast lane to high-quality products.

2. Why choose Zhejiang Xinfeng Machinery? Uncover the unique charm of its customized casting molds!

Under the highly customized market demand, Zhejiang Xinfeng Machinery Co., Ltd. has won wide acclaim from customers for its excellent customized casting mold services. We know that every company's products are unique, so we provide a full range of customized services from design consultation, mold development to production and manufacturing. Whether it is low-pressure, differential pressure or gravity casting molds, we can tailor them according to the specific needs of customers to ensure that the molds are optimal in terms of material selection, structural design, dimensional accuracy and surface finish.

We have an experienced technical team who are proficient in various casting processes and can provide customers with professional technical support and solutions. Whether facing complex process problems or urgent production needs, we can respond quickly to ensure the smooth progress of customer projects. Choosing Zhejiang Xinfeng Machinery means choosing a partner who can understand you, support you, and grow with you.

3. How to shorten the product launch cycle? How can Zhejiang Xinfeng Machinery's casting molds help?

In a rapidly changing market environment, time is the lifeline of an enterprise. In order to help customers seize the market opportunity, Zhejiang Xinfeng Machinery Co., Ltd. is committed to shortening the product launch cycle by optimizing the production process and improving production efficiency. We use advanced project management methods to ensure that every link from mold design to production and manufacturing is closely connected and operates efficiently. At the same time, we have introduced first-class automated production equipment to improve production efficiency and product quality stability. For relatively simple production processes such as gravity casting molds, we have achieved rapid response and flexible production through standardized operations and continuous improvement. Whether it is mass production or small batch trial production, we can quickly adjust the production plan to ensure the timely delivery of high-quality products. In addition, we have established a complete after-sales service system to provide customers with timely technical support and solutions to ensure that customers have no worries during use. Choosing Zhejiang Xinfeng Machinery's casting mold service is choosing a capable assistant who can help you respond to the market quickly and gain a competitive advantage.

English

English 中文简体

中文简体