Precision plays a fundamental role in the production of wheel hub motorcycle casting molds. The wheel hub is a critical component of the motorcycle, responsible for supporting the wheel and ensuring s...

Casting Core Box Molds Suppliers

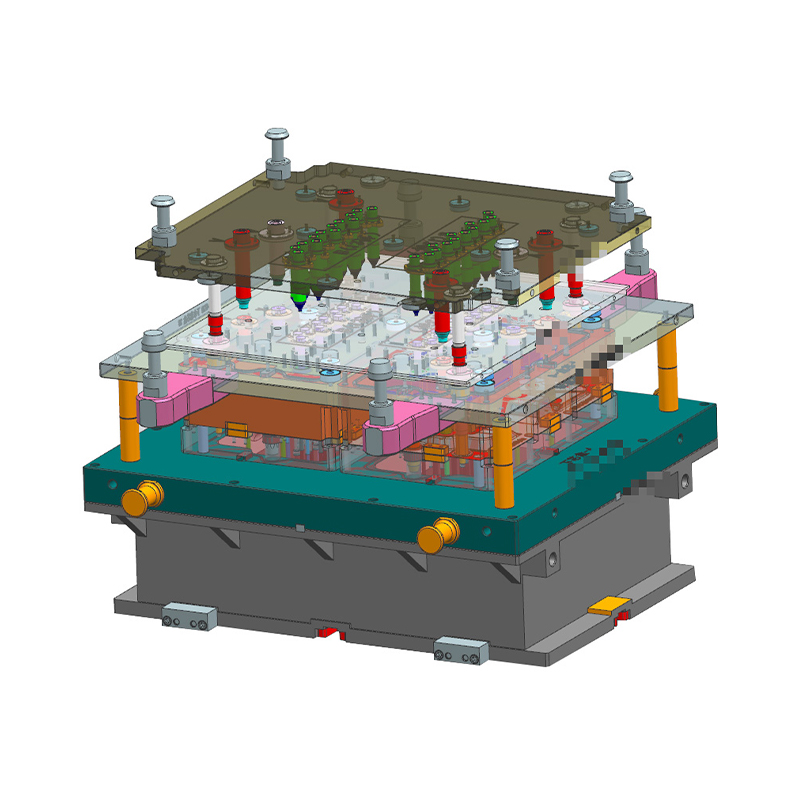

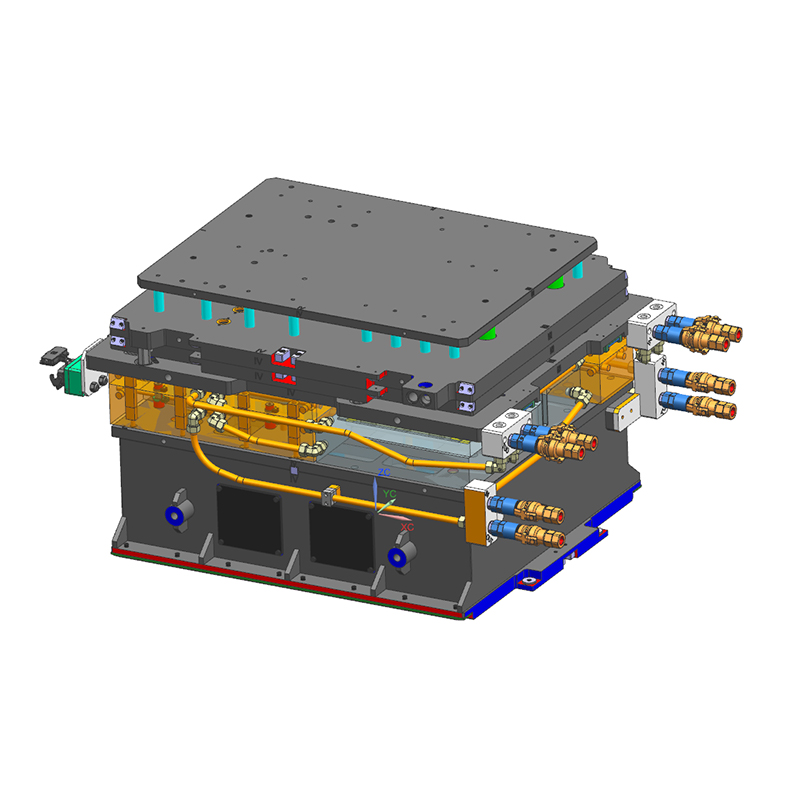

Casting Core Box Molds are an indispensable key component in the casting process. This type of mold is specially designed to manufacture cores, which play a key role in forming the internal cavity or complex structure of the casting during the casting process. Our Casting Core Box Molds are made of high-quality materials, with precise processing accuracy and excellent durability. They can ensure the precise molding of the core to meet the strict requirements of the casting for internal structure and dimensional accuracy. Our molds can handle complex internal structures and fine details. These molds are widely used in high-end manufacturing fields such as automobiles, aerospace, machinery manufacturing, and ships, providing strong support for the production of various castings with high precision and high quality requirements. We also provide customized services, designing and manufacturing molds according to the specific needs of customers to meet the special needs of different casting production.

Zhejiang Xinfeng Machinery Co., Ltd. is professional China Casting Core Box Molds Suppliers and Custom Casting Core Box Molds Manufacturers.Zhejiang Xinfeng Machinery and Shengzhou Yuanfeng Mold are subsidiaries of Yongfeng Mold Group, with over 380 employees and annual sales of 550 million. Xinfeng specializes in aluminum wheel hub and structural casting molds, covering 30 acres, with a 16,000+ sqm plant, outputting 1,800 sets of molds annually, employing over 130 staff, including 30 skilled technicians and designers using CAD, UG, CATIA, etc. The company focuses on customer needs, innovation, and quality, implementing a mold production progress system and equipped with advanced machinery like CNC centers.

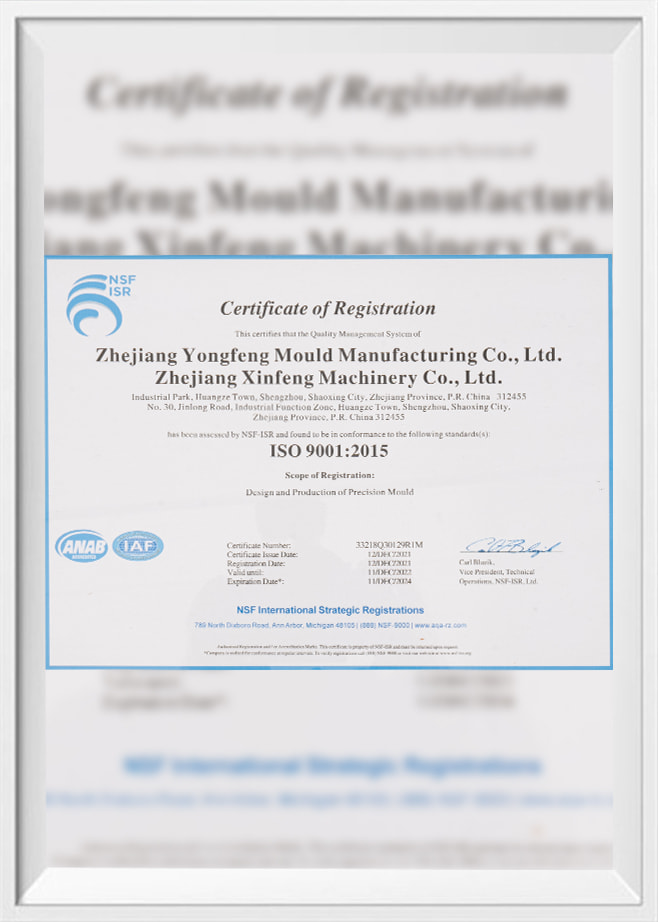

Yuanfeng Mold Co., Ltd. was established in Yongfeng Group, focusing on mold steel forging products, with multiple forging and electro slag remelting production lines, mainly producing mold raw materials such as H13 series and 35CrMo. The company actively promotes technological innovation and brand innovation, strengthens quality management, enhances corporate image, complies with ISO9001:2015 international quality system standards, and has won the titles of Shengzhou City's "30 Best" Enterprises, Integrity Enterprises, and National High-tech Enterprises.

Xinfeng Machinery actively participates in the "waste-free factory construction" and became a member of the "waste-free factory" in October 2022. It maintains long-term strategic cooperation with nearly 40 wheel hub factories and aluminum casting manufacturers, ranks among the top three in the aluminum alloy casting mold industry, leads the casting process industry, and produces 2,000 sets of molds annually. It is committed to using technology to improve product quality and using craftsmanship to create each product.

-

-

A wheel hub motorcycle casting mold is an essential tool in the manufacturing process of motorcycle wheel hubs. It plays a key role in shaping the molten metal into the precise dimensions required for...

-

A wheel hub differential pressure casting mold is a specialized mold used in the casting process to produce wheel hubs, commonly found in vehicles. The “differential pressure casting” technique involv...

1.What are the different types of casting core box molds?

Casting core box molds are essential components in the foundry industry, used to create the core structures within cast metal products. They can be divided into three main types based on the binder used and the curing method: cold core boxes, inorganic core boxes, and hot core boxes.

Cold Core Boxes: Cold core boxes use organic resin binders to create sand cores, which are then rapidly cured by blowing in a catalyst gas. This curing process is efficient, leading to quick setting and a high production rate. The primary advantage of cold core boxes is their ability to produce cores with high surface quality and dimensional precision. This is particularly valuable in industries where complex and high-precision castings are required, such as aerospace and automotive manufacturing. The fast curing speed enables manufacturers to maintain a high throughput, making cold core boxes ideal for high-volume production environments.

Inorganic Core Boxes: Inorganic core boxes use inorganic binders, such as water glass (sodium silicate), which react chemically or are cured by heating. This method eliminates the need for organic catalysts, which reduces the environmental impact of the casting process. Inorganic core boxes are known for their excellent high-temperature resistance, making them suitable for casting high-temperature metals like iron and steel. These core boxes produce cores with good mechanical strength and thermal stability. Additionally, the lack of organic materials means that there are no harmful gas emissions during the curing process, making this method more environmentally friendly. Inorganic core boxes are often used in applications such as engine blocks and exhaust manifolds, where durability and temperature resistance are critical.

Hot Core Boxes: Hot core boxes use thermosetting binders that are cured by heating. The curing process in hot core boxes is slower compared to cold core boxes, but the resulting cores have high strength and good dimensional stability. This makes hot core boxes suitable for producing large and complex castings, such as mechanical equipment parts and pipe fittings. The slower curing time allows for more precise control over the core's final properties, which is important for applications where dimensional accuracy and mechanical performance are crucial. Hot core boxes are particularly valuable in industries where large-scale and intricate castings are required, providing the necessary strength and stability to withstand the demands of these applications.

2.How do cold core boxes enhance production efficiency?

Cold core boxes are highly effective in enhancing production efficiency due to several key factors related to their design and curing process. The primary advantage of cold core boxes is their rapid curing speed. This efficiency is achieved through the use of organic resin binders combined with a catalyst gas, which accelerates the curing process significantly. This rapid curing allows manufacturers to produce cores quickly, thus increasing the overall throughput of the production line.

The speed at which cold core boxes cure also impacts the overall efficiency of the manufacturing process. Traditional sand core production methods can be time-consuming, but the cold core box process reduces the time needed for each core to set, allowing for faster production cycles. This is particularly beneficial in high-volume production environments where large quantities of cores are required in a short period. The ability to produce cores quickly without compromising on quality ensures that production schedules are met and helps to maintain a steady workflow.

Additionally, cold core boxes are designed to produce cores with high surface finish and precision. The quality of the cores produced using cold core boxes is typically superior, with smooth surfaces and accurate dimensions. This high level of precision reduces the need for post-processing and finishing, which can be time-consuming and costly. By minimizing the need for additional finishing work, manufacturers can further streamline their production processes and reduce overall costs.

Cold core boxes are also versatile and can be used to produce a wide range of core shapes and sizes. This flexibility allows manufacturers to adapt to varying production requirements and handle complex core designs with ease. The ability to quickly switch between different core types and sizes contributes to the overall efficiency of the production process.

3.Why are inorganic core boxes considered environmentally friendly?

Inorganic core boxes are recognized for their environmental benefits due to the nature of their binders and curing processes. The primary binder used in inorganic core boxes is water glass, also known as sodium silicate. Unlike organic binders, which can release harmful gases during curing, inorganic binders do not produce volatile organic compounds (VOCs) or other pollutants. This absence of VOCs makes inorganic core boxes a more environmentally friendly option for core production.

The curing process for inorganic core boxes involves either chemical reactions or heating, both of which do not require the use of organic catalysts. This further reduces the environmental impact, as there are no additional chemicals introduced into the process that could potentially harm the environment. The lack of organic materials in the core box also means that there are no residual pollutants left after the curing process, contributing to a cleaner production environment.

Inorganic core boxes also offer excellent high-temperature resistance, which is essential for casting processes involving high-temperature metals. The ability to withstand high temperatures without degrading or releasing harmful substances makes them suitable for applications such as engine blocks, exhaust manifolds, and other components exposed to extreme conditions. This durability is beneficial not only for the quality of the castings but also for maintaining a safe and environmentally responsible production process.

The environmental benefits of inorganic core boxes extend beyond the production phase. The cores produced using inorganic binders are often easier to handle and dispose of, as they do not contain hazardous materials that require special treatment. This ease of disposal contributes to a more sustainable manufacturing process and reduces the potential environmental impact of waste management.

English

English 中文简体

中文简体