Precision plays a fundamental role in the production of wheel hub motorcycle casting molds. The wheel hub is a critical component of the motorcycle, responsible for supporting the wheel and ensuring s...

Casting Tooling Fixture Molds Suppliers

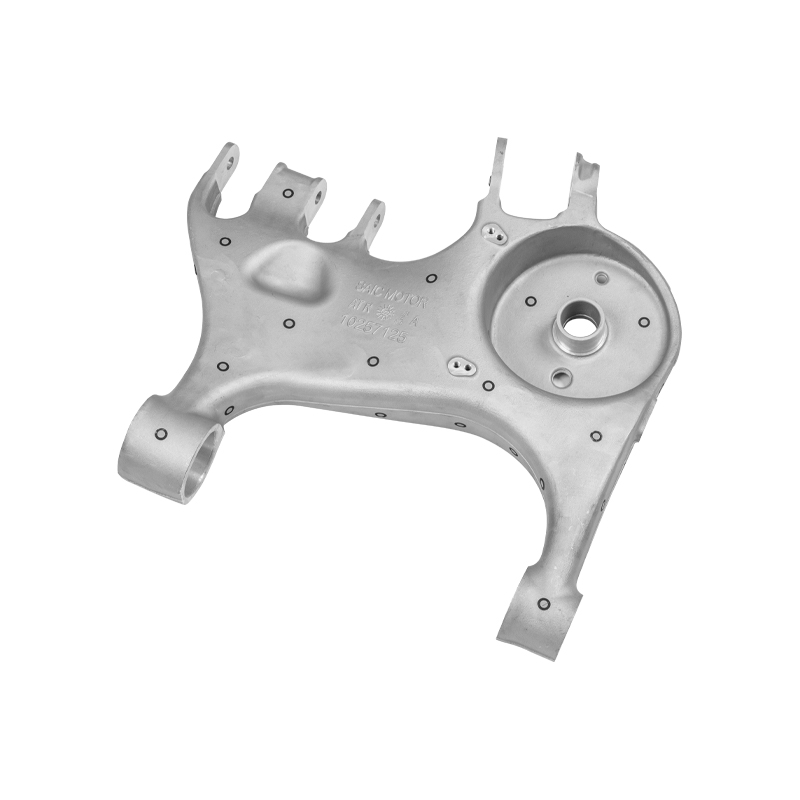

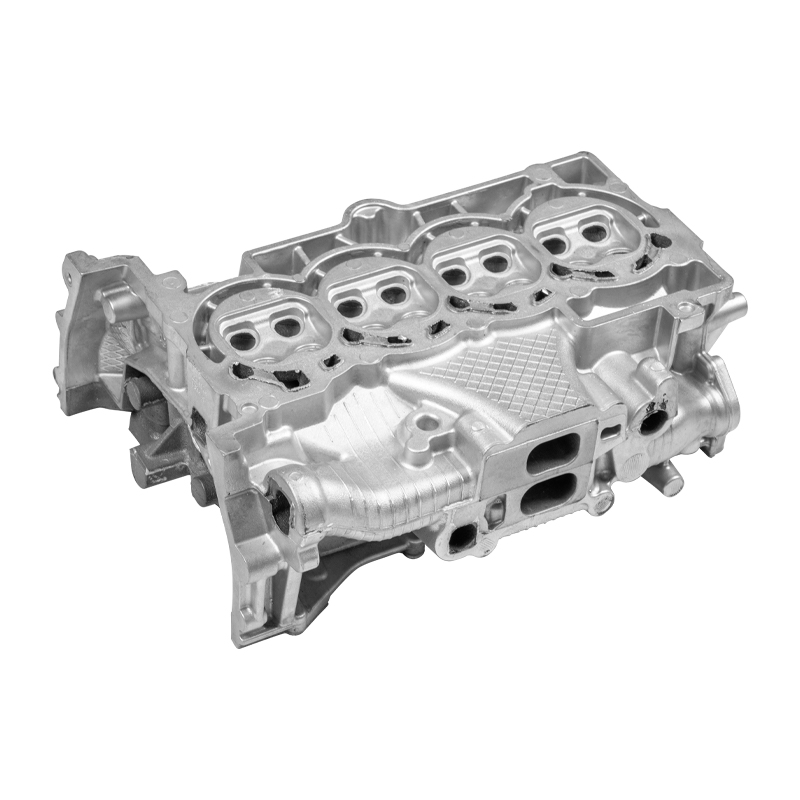

Casting Tooling Fixture Molds are key equipment used to fix and support workpieces during the casting process. They are commonly used in manufacturing processes such as metal casting and plastic injection molding to ensure precise positioning, stability and shape consistency of the workpiece. The design and production of casting tooling fixture molds need to be customized according to the shape, size and casting process requirements of the specific product, with a high degree of precision and durability. These molds are widely used in automotive manufacturing, aerospace, machining, construction and electronics industries, and play a key role in the production process of parts that require complex geometries and high precision. Using high-quality casting tooling fixture molds can not only improve production efficiency, but also greatly reduce production errors caused by workpiece deformation or inaccurate positioning, ensuring product quality and consistency.

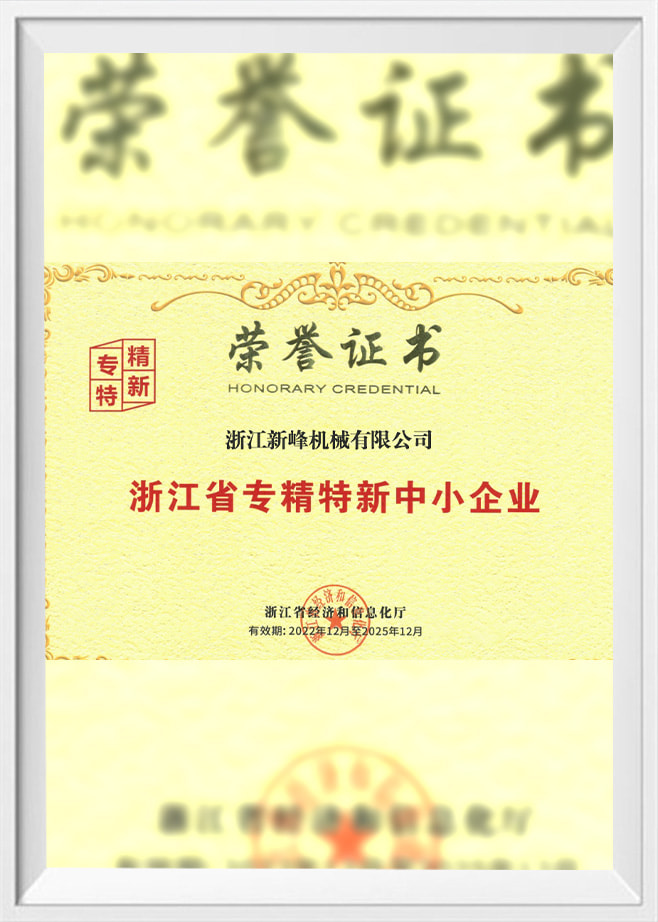

Zhejiang Xinfeng Machinery Co., Ltd. is professional China Casting Tooling Fixture Molds Suppliers and Custom Casting Tooling Fixture Molds Manufacturers.Zhejiang Xinfeng Machinery and Shengzhou Yuanfeng Mold are subsidiaries of Yongfeng Mold Group, with over 380 employees and annual sales of 550 million. Xinfeng specializes in aluminum wheel hub and structural casting molds, covering 30 acres, with a 16,000+ sqm plant, outputting 1,800 sets of molds annually, employing over 130 staff, including 30 skilled technicians and designers using CAD, UG, CATIA, etc. The company focuses on customer needs, innovation, and quality, implementing a mold production progress system and equipped with advanced machinery like CNC centers.

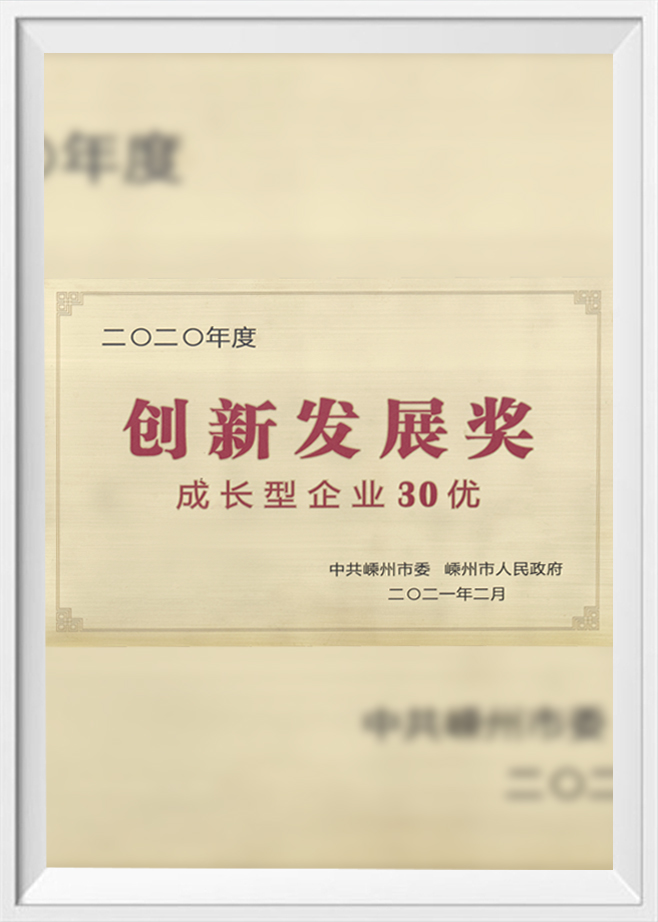

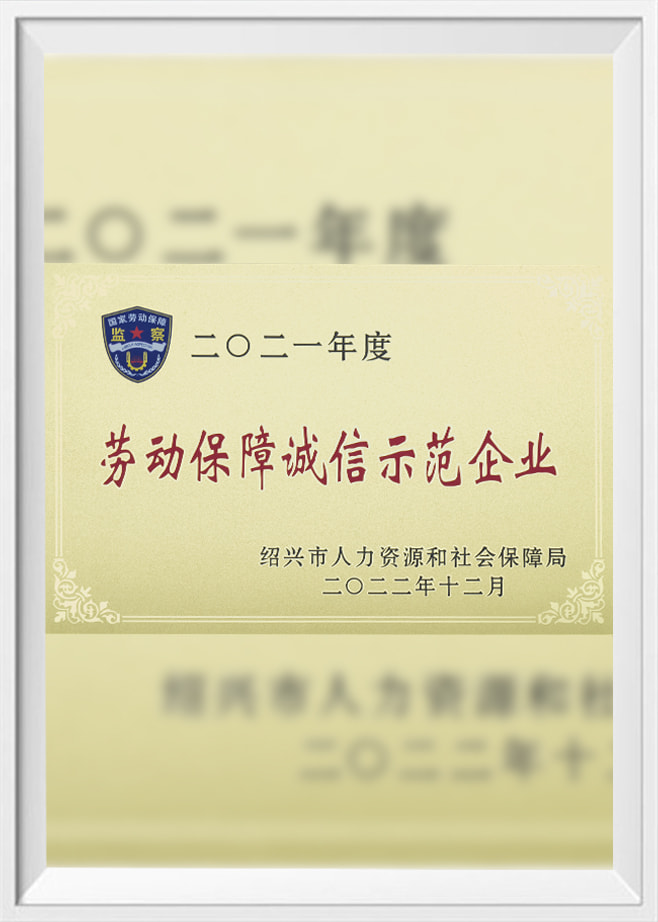

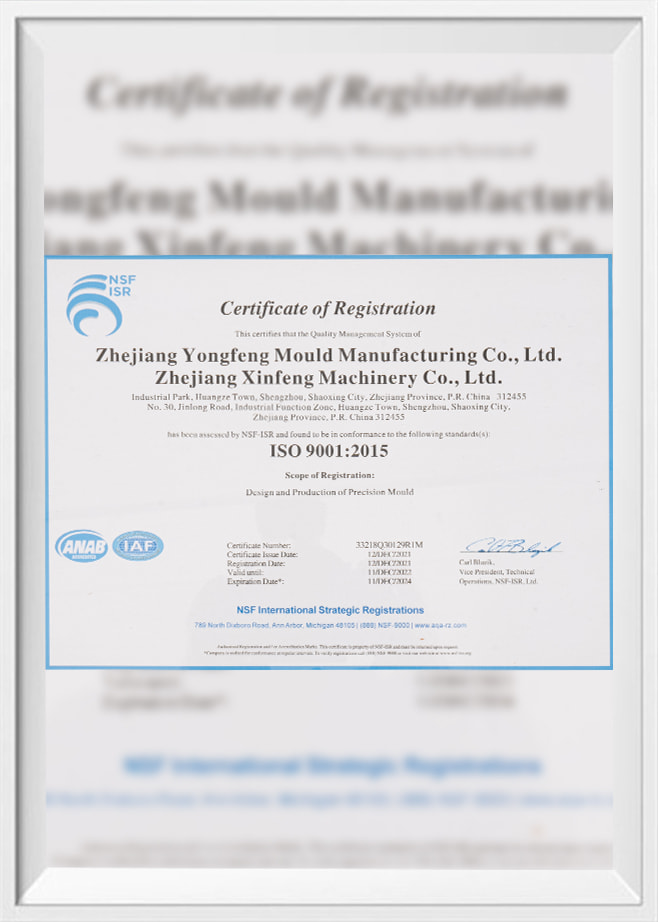

Yuanfeng Mold Co., Ltd. was established in Yongfeng Group, focusing on mold steel forging products, with multiple forging and electro slag remelting production lines, mainly producing mold raw materials such as H13 series and 35CrMo. The company actively promotes technological innovation and brand innovation, strengthens quality management, enhances corporate image, complies with ISO9001:2015 international quality system standards, and has won the titles of Shengzhou City's "30 Best" Enterprises, Integrity Enterprises, and National High-tech Enterprises.

Xinfeng Machinery actively participates in the "waste-free factory construction" and became a member of the "waste-free factory" in October 2022. It maintains long-term strategic cooperation with nearly 40 wheel hub factories and aluminum casting manufacturers, ranks among the top three in the aluminum alloy casting mold industry, leads the casting process industry, and produces 2,000 sets of molds annually. It is committed to using technology to improve product quality and using craftsmanship to create each product.

-

-

A wheel hub motorcycle casting mold is an essential tool in the manufacturing process of motorcycle wheel hubs. It plays a key role in shaping the molten metal into the precise dimensions required for...

-

A wheel hub differential pressure casting mold is a specialized mold used in the casting process to produce wheel hubs, commonly found in vehicles. The “differential pressure casting” technique involv...

1. Zhejiang Xinfeng Machinery Co., Ltd.: Leading a new era of high-precision manufacturing of Tooling Fixture Molds

In the field of precision manufacturing, tooling fixture molds are key tools to ensure the precise positioning and stability of workpieces during the production and assembly process. Their importance is self-evident. Zhejiang Xinfeng Machinery Co., Ltd., as a leader in the industry, is well aware of the importance of high precision and high durability for tooling fixture molds. We use the most advanced design concepts and manufacturing technologies, combined with customers' specific workpiece shapes, sizes and production process requirements, to carry out one-to-one customized design. We select high-strength, wear-resistant high-quality materials, such as high-grade alloy steel and cemented carbide, to ensure that the molds maintain excellent precision and stability under long-term high-load operation. Zhejiang Xinfeng Machinery Co., Ltd.'s tooling fixture molds not only meet customers' high standards for product quality, but also lay a solid foundation for improving overall production efficiency.

2. Intelligent upgrade: Zhejiang Xinfeng Machinery Co., Ltd. Tooling Fixture Molds and deep integration of automation technology

With the rise of intelligent manufacturing, Zhejiang Xinfeng Machinery Co., Ltd. keeps pace with the times and deeply integrates tooling fixture molds with automation equipment and intelligent control systems. By integrating positioning, clamping, guiding, measurement and detection, our molds can accurately control every link of the workpiece in the production process, greatly improving production efficiency and processing accuracy. In addition, combined with advanced technologies such as machine vision and sensors, automatic detection and adjustment of molds can be achieved, reducing human errors and ensuring the continuous stability of product quality. Zhejiang Xinfeng Machinery Co., Ltd.'s intelligent tooling fixture molds not only improve the automation level of the production line, but also bring customers unprecedented production experience and value.

3. Wide application, outstanding contribution: Zhejiang Xinfeng Machinery Co., Ltd. Tooling Fixture Molds help high-quality development of multiple industries

Zhejiang Xinfeng Machinery Co., Ltd.'s tooling fixture molds play an important role in many fields such as automobiles, aerospace, electronic assembly, and mechanical processing due to their excellent performance and wide applicability. In the automotive manufacturing industry, our molds provide a strong guarantee for the precise assembly of complex parts, reduce scrap and rework rates, and improve the quality and safety of the vehicle. In the aerospace field, facing extreme working environments and stringent performance requirements, our molds can still operate stably and reliably, contributing to the manufacturing of high-precision products. In addition, in industries such as electronic assembly and mechanical processing, Zhejiang Xinfeng Machinery Co., Ltd.'s tooling fixture molds also demonstrate strong competitiveness and market adaptability, helping customers achieve efficient, precise, and high-quality production goals. We firmly believe that through continuous technological innovation and service optimization, Zhejiang Xinfeng Machinery Co., Ltd. will work with more partners to jointly promote the development of various industries towards higher quality and higher efficiency.

English

English 中文简体

中文简体