Precision plays a fundamental role in the production of wheel hub motorcycle casting molds. The wheel hub is a critical component of the motorcycle, responsible for supporting the wheel and ensuring s...

Wheel Hub Differential Pressure Casting Mold Manufacturers

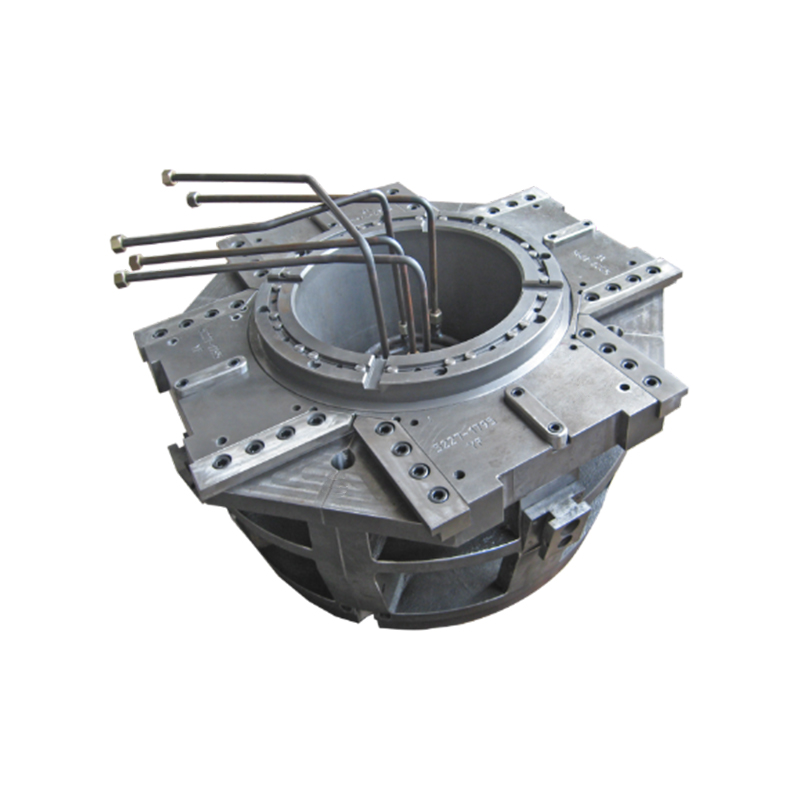

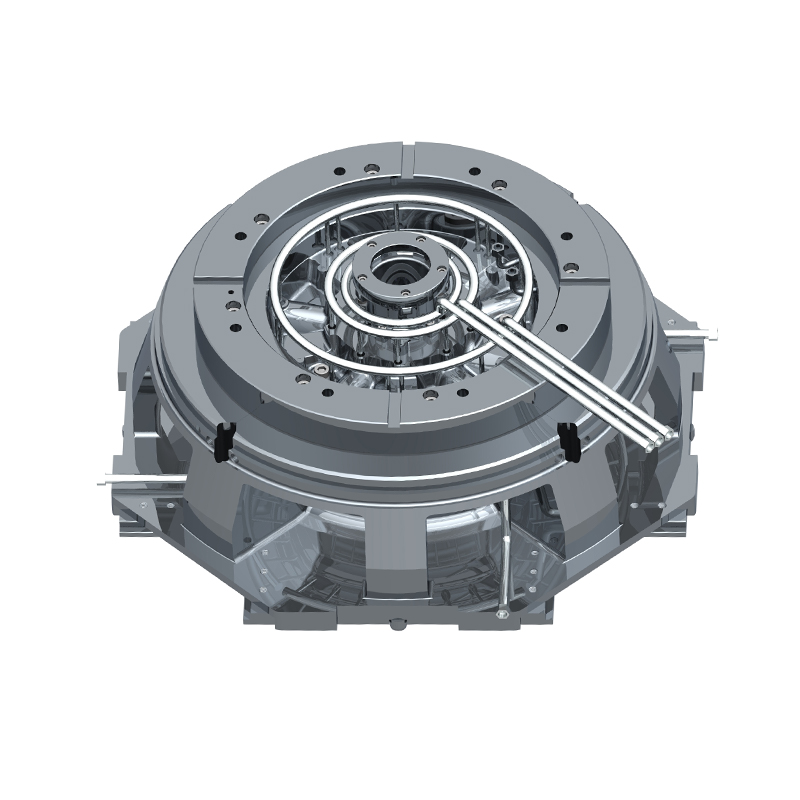

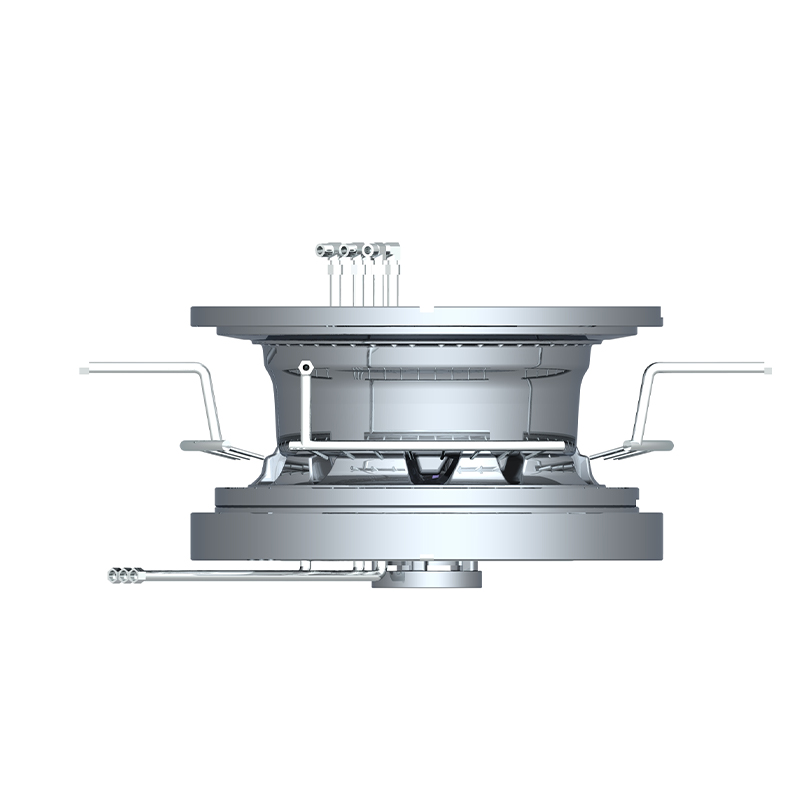

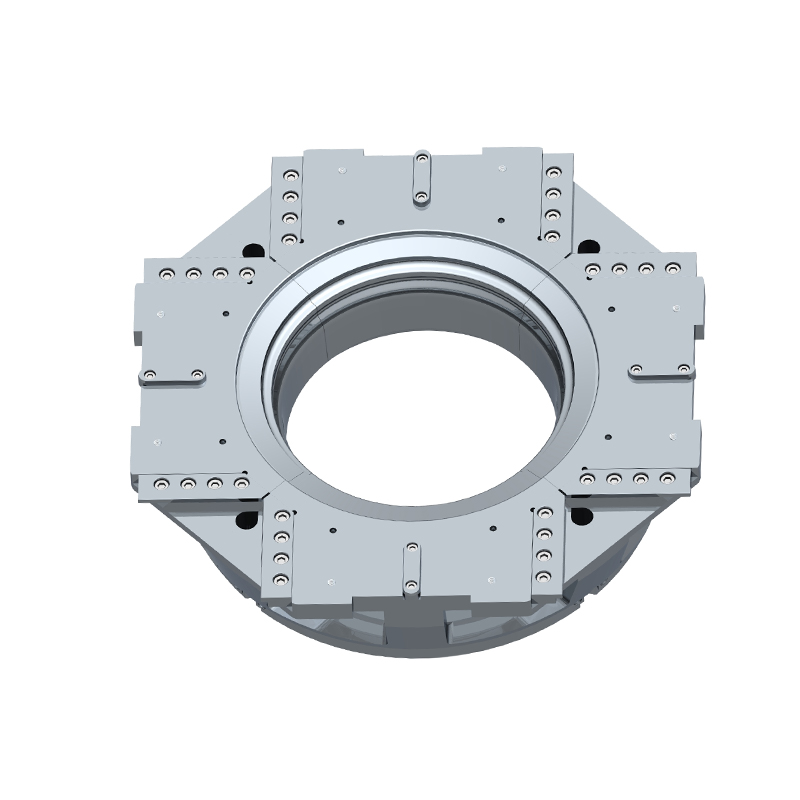

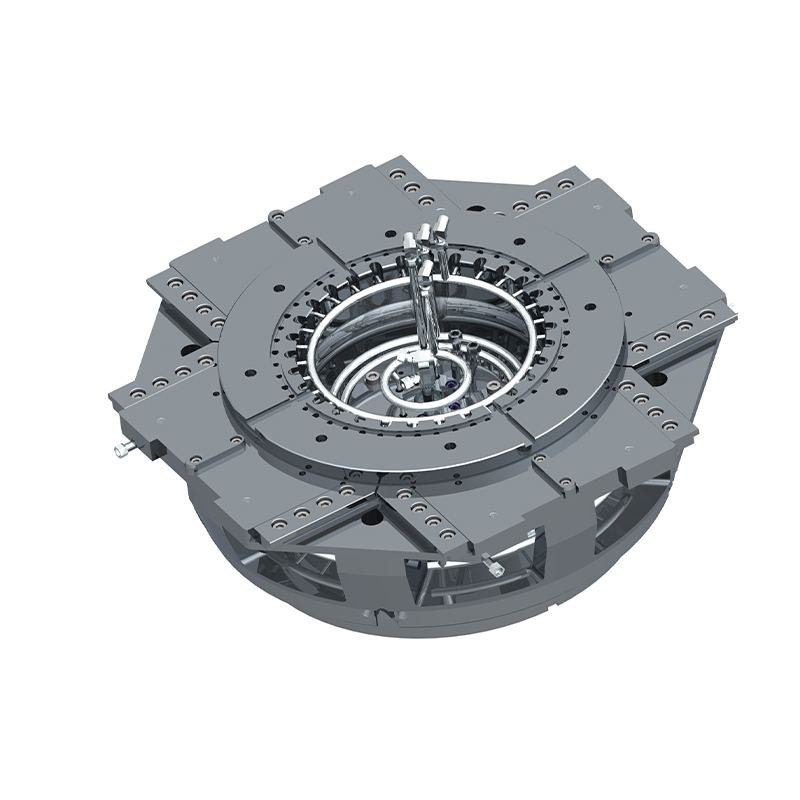

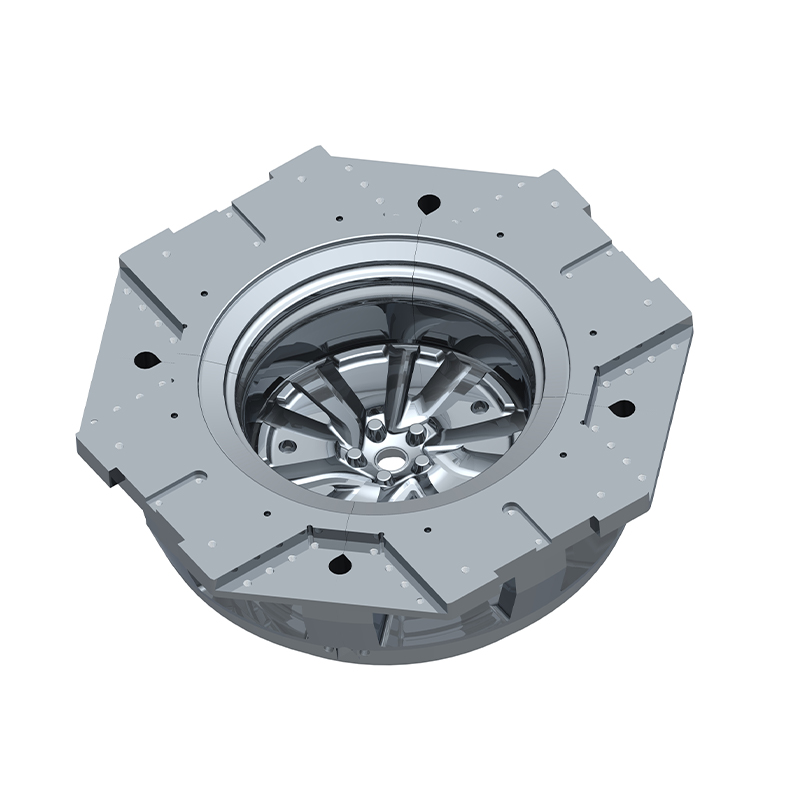

Wheel hub differential pressure casting mold is a casting mold specially used for manufacturing automobile wheels, which adopts differential pressure casting technology. Differential pressure casting optimizes the fluidity and filling of metal by applying different pressures during the casting process, thereby producing high-quality castings. The mold is usually made of high-strength alloy materials, can withstand high pressure and temperature, and has a complex internal structure to ensure the precise molding of the wheel hub shape. In actual operation, the differential pressure casting process injects molten metal into the mold cavity through the gate system. During the metal injection process, high pressure is applied to ensure that the metal fills the entire mold quickly and evenly. This high-pressure effect continues during the solidification stage of the metal to reduce the formation of pores and shrinkage cavities, ensuring the density and better mechanical properties of the casting. The inside of the mold is preheated to an appropriate temperature to prevent the molten metal from cooling too quickly, thereby further improving the quality of the casting. After the metal cools and solidifies in the mold, the casting is removed from the mold by a mechanical or automated system. Due to the high durability of the mold, it can be used repeatedly and is suitable for mass production.

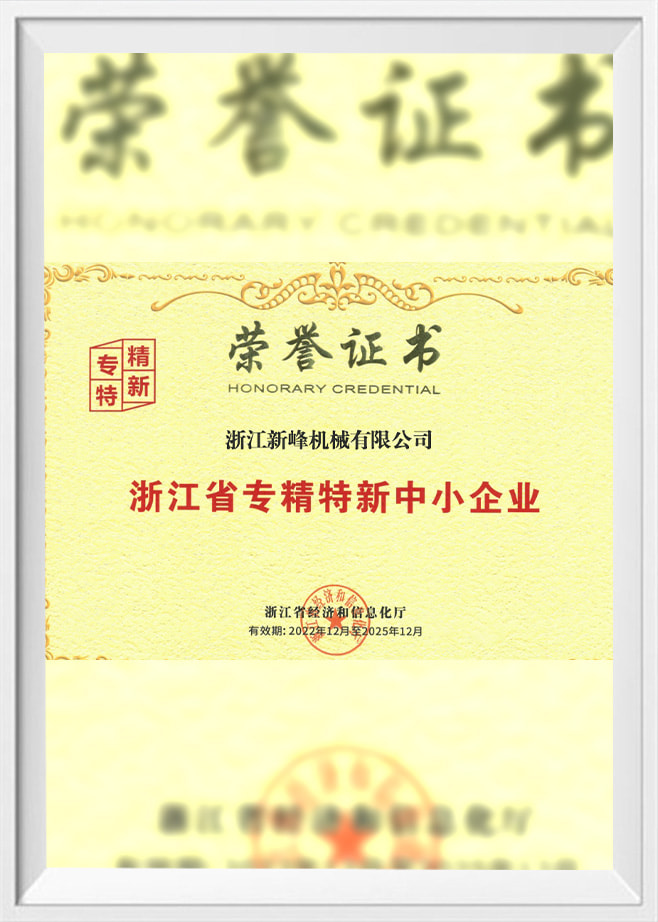

Zhejiang Xinfeng Machinery Co., Ltd. is professional China Wheel Hub Differential Pressure Casting Mold Manufacturers and Custom Wheel Hub Differential Pressure Casting Mold Factory.Zhejiang Xinfeng Machinery and Shengzhou Yuanfeng Mold are subsidiaries of Yongfeng Mold Group, with over 380 employees and annual sales of 550 million. Xinfeng specializes in aluminum wheel hub and structural casting molds, covering 30 acres, with a 16,000+ sqm plant, outputting 1,800 sets of molds annually, employing over 130 staff, including 30 skilled technicians and designers using CAD, UG, CATIA, etc. The company focuses on customer needs, innovation, and quality, implementing a mold production progress system and equipped with advanced machinery like CNC centers.

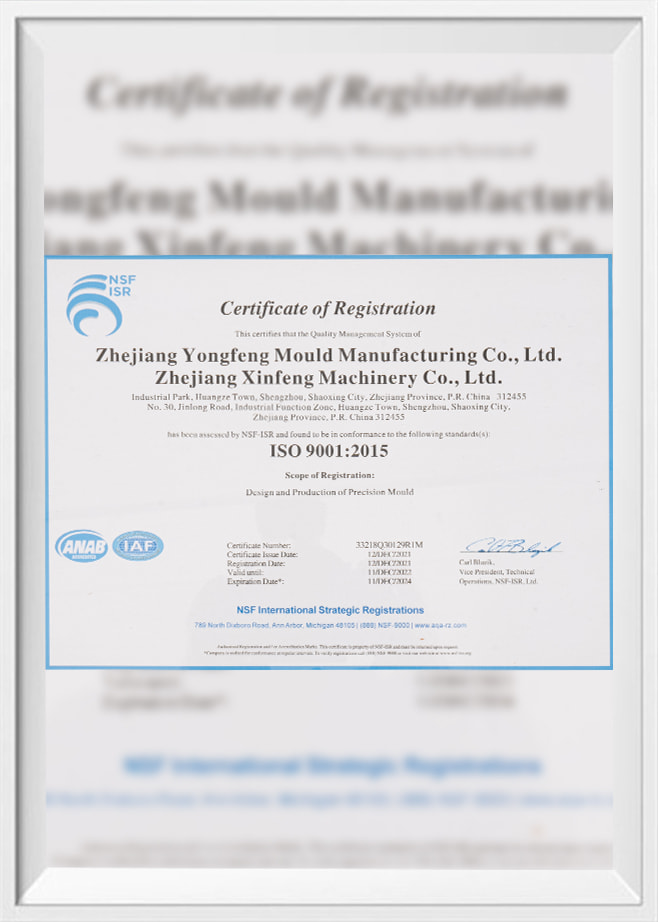

Yuanfeng Mold Co., Ltd. was established in Yongfeng Group, focusing on mold steel forging products, with multiple forging and electro slag remelting production lines, mainly producing mold raw materials such as H13 series and 35CrMo. The company actively promotes technological innovation and brand innovation, strengthens quality management, enhances corporate image, complies with ISO9001:2015 international quality system standards, and has won the titles of Shengzhou City's "30 Best" Enterprises, Integrity Enterprises, and National High-tech Enterprises.

Xinfeng Machinery actively participates in the "waste-free factory construction" and became a member of the "waste-free factory" in October 2022. It maintains long-term strategic cooperation with nearly 40 wheel hub factories and aluminum casting manufacturers, ranks among the top three in the aluminum alloy casting mold industry, leads the casting process industry, and produces 2,000 sets of molds annually. It is committed to using technology to improve product quality and using craftsmanship to create each product.

-

-

A wheel hub motorcycle casting mold is an essential tool in the manufacturing process of motorcycle wheel hubs. It plays a key role in shaping the molten metal into the precise dimensions required for...

-

A wheel hub differential pressure casting mold is a specialized mold used in the casting process to produce wheel hubs, commonly found in vehicles. The “differential pressure casting” technique involv...

1.What is a Wheel Hub Differential Pressure Casting Mold?

A wheel hub differential pressure casting mold is a crucial tool in the automotive industry, specifically designed for the precision manufacturing of wheel hubs. These molds utilize differential pressure casting technology, a method that optimizes the flow and filling of molten metal by applying different levels of pressure throughout the casting process. This process results in superior castings, which are essential for the safety and performance of automobiles.

The mold itself is typically constructed from high-strength alloy materials, designed to withstand extreme temperatures and pressures during the casting process. This durability is essential because the molds are subjected to intense conditions that can cause wear and tear over time. By using high-strength alloys, manufacturers ensure that these molds can be reused multiple times, making the process cost-effective for mass production. The design of the mold is highly complex, incorporating intricate internal structures that allow for the precise shaping of the wheel hub. This complexity is necessary to ensure the final product meets strict dimensional and performance standards required in the automotive industry.

The differential pressure casting process begins by preheating the mold to a specific temperature. This preheating is crucial as it prevents the molten metal from cooling too quickly once it is introduced into the mold, ensuring an even distribution of metal throughout the cavity. The metal is injected into the mold through a gate system, and high pressure is applied to the molten metal during the injection phase. This high pressure ensures that the molten metal fills the entire mold quickly and evenly, reducing the risk of defects such as voids or incomplete fill.

Once the metal has filled the mold, the pressure is maintained throughout the solidification process. This continuous pressure reduces the formation of pores and shrinkage cavities, leading to a denser, more robust casting with superior mechanical properties. After the metal has fully cooled and solidified, the casting is removed from the mold, usually through a mechanical or automated system. This efficient process allows for the repeated production of high-quality wheel hubs, making it ideal for large-scale automotive manufacturing.

2.How Does the Differential Pressure Casting Process Work?

Differential pressure casting is a specialized process that significantly improves the quality of metal castings, particularly in the production of complex automotive components like wheel hubs. The process begins with the preparation of the mold, which is preheated to a specific temperature to ensure the molten metal remains fluid during injection. Preheating the mold prevents premature cooling, which could result in an incomplete or defective casting. This step is critical because if the metal cools too quickly, it may not fill the mold completely, leading to flaws that can weaken the final product.

Once the mold is preheated, molten metal is injected into the mold cavity through a gate system. The use of a gate system allows for controlled entry of the molten metal, ensuring that it flows smoothly into the mold without creating turbulence or air pockets, which can lead to defects. During the injection process, high pressure is applied to force the molten metal into all the intricate parts of the mold, ensuring that every corner and detail of the mold is filled. This is particularly important in the case of wheel hubs, which have complex shapes that must be replicated with high precision to meet performance standards.

The high pressure applied during this phase serves multiple purposes. It ensures rapid and uniform filling of the mold, reducing the likelihood of incomplete castings. It minimizes the formation of air bubbles, shrinkage cavities, and other casting defects that can compromise the strength and durability of the wheel hub. The continuous application of pressure during the solidification phase also ensures that the metal remains densely packed as it cools, further improving the mechanical properties of the casting. This results in a final product that is not only precise in shape but also has superior structural integrity.

English

English 中文简体

中文简体