Precision plays a fundamental role in the production of wheel hub motorcycle casting molds. The wheel hub is a critical component of the motorcycle, responsible for supporting the wheel and ensuring s...

Wheel Hub Gravity Casting Mold Manufacturers

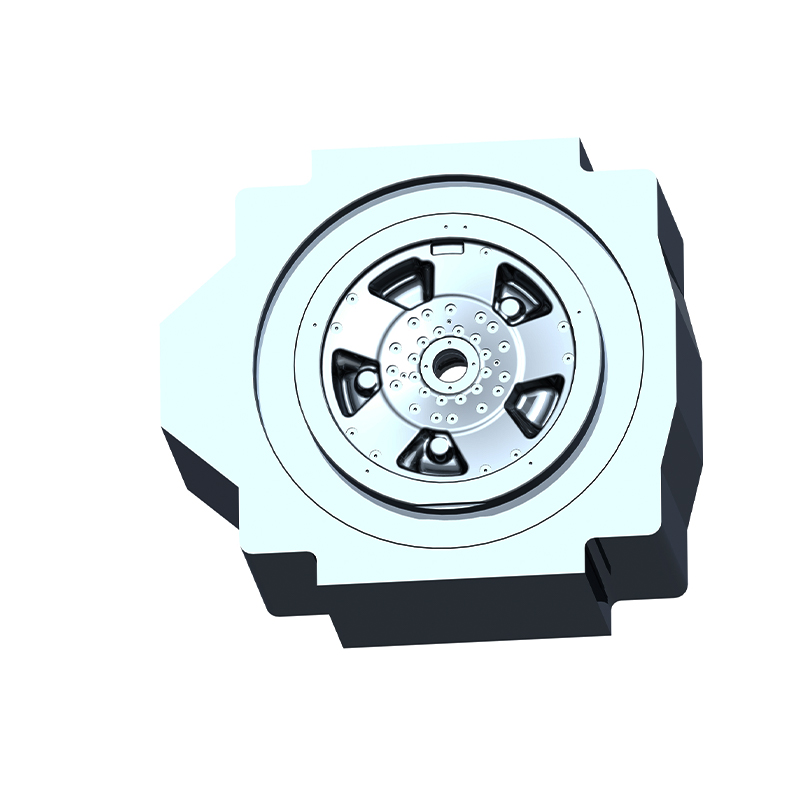

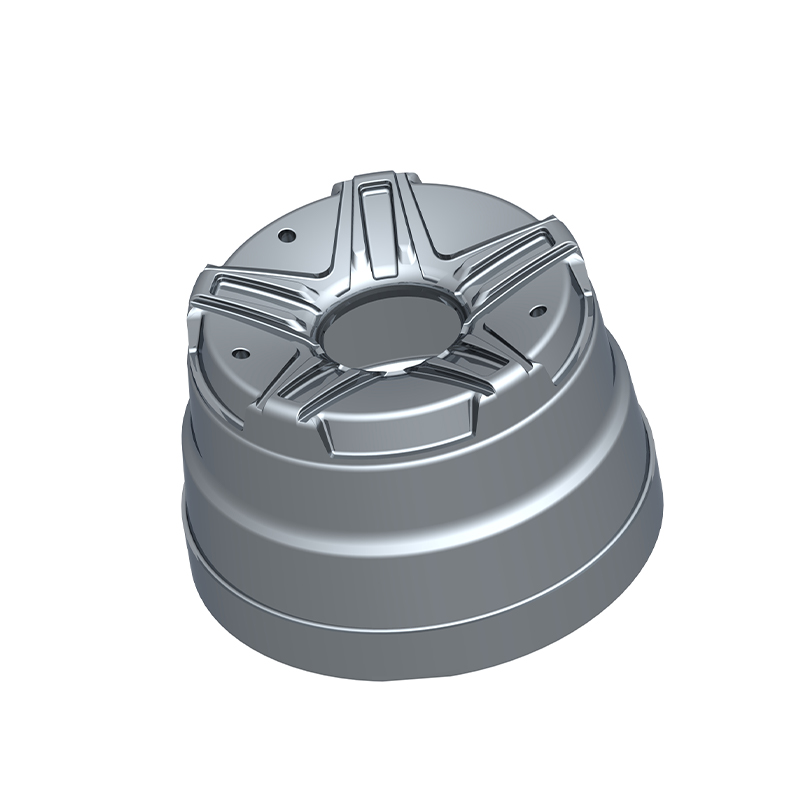

Wheel hub gravity casting mold is a casting mold used to manufacture automotive wheels using a gravity casting process. In this process, molten metal is introduced into a preheated mold to fill the mold cavity from top to bottom by the earth's gravity. As the metal cools and solidifies, a wheel hub casting with the desired shape and structure is formed. This casting method is simple and low-cost, suitable for small and medium-scale production and low-pressure casting needs. Due to its process characteristics, wheel hub castings can maintain good mechanical properties and surface quality and are widely used in the automotive industry. The versatility of gravity casting is not limited to automotive wheels but also includes a variety of other components in automotive manufacturing and other fields, such as engine components, brackets, and structural elements. Its ability to produce complex designs at relatively low production costs and energy consumption further enhances its appeal in industries where efficiency and economy are crucial.

Zhejiang Xinfeng Machinery Co., Ltd. is professional China Wheel Hub Gravity Casting Mold Manufacturers and Custom Wheel Hub Gravity Casting Mold Factory.Zhejiang Xinfeng Machinery and Shengzhou Yuanfeng Mold are subsidiaries of Yongfeng Mold Group, with over 380 employees and annual sales of 550 million. Xinfeng specializes in aluminum wheel hub and structural casting molds, covering 30 acres, with a 16,000+ sqm plant, outputting 1,800 sets of molds annually, employing over 130 staff, including 30 skilled technicians and designers using CAD, UG, CATIA, etc. The company focuses on customer needs, innovation, and quality, implementing a mold production progress system and equipped with advanced machinery like CNC centers.

Yuanfeng Mold Co., Ltd. was established in Yongfeng Group, focusing on mold steel forging products, with multiple forging and electro slag remelting production lines, mainly producing mold raw materials such as H13 series and 35CrMo. The company actively promotes technological innovation and brand innovation, strengthens quality management, enhances corporate image, complies with ISO9001:2015 international quality system standards, and has won the titles of Shengzhou City's "30 Best" Enterprises, Integrity Enterprises, and National High-tech Enterprises.

Xinfeng Machinery actively participates in the "waste-free factory construction" and became a member of the "waste-free factory" in October 2022. It maintains long-term strategic cooperation with nearly 40 wheel hub factories and aluminum casting manufacturers, ranks among the top three in the aluminum alloy casting mold industry, leads the casting process industry, and produces 2,000 sets of molds annually. It is committed to using technology to improve product quality and using craftsmanship to create each product.

-

-

A wheel hub motorcycle casting mold is an essential tool in the manufacturing process of motorcycle wheel hubs. It plays a key role in shaping the molten metal into the precise dimensions required for...

-

A wheel hub differential pressure casting mold is a specialized mold used in the casting process to produce wheel hubs, commonly found in vehicles. The “differential pressure casting” technique involv...

1. The Essence of Wheel Hub Gravity Casting Mold: Process & Benefits

Wheel Hub Gravity Casting Mold represents a straightforward yet sophisticated approach to metal casting. The process involves pouring molten metal into a preheated mold, where it is guided by gravity to fill the intricate cavities from top to bottom. As the metal cools and solidifies, it forms a wheel hub casting with precise dimensions, complex geometries, and desired mechanical properties. The simplicity of this method, coupled with its low-cost operation, makes it an ideal choice for small to medium-scale production runs and low-pressure casting requirements.

The benefits of Wheel Hub Gravity Casting Mold extend beyond its economic advantages. The castings exhibit excellent mechanical properties, such as high strength and durability, thanks to the gradual cooling process that reduces internal stresses and porosity. Moreover, the surface quality of the castings is remarkable, ensuring a smooth finish that requires minimal post-processing. These factors, combined with the ability to produce complex designs at low costs and energy consumption, make Wheel Hub Gravity Casting Mold a compelling choice for the automotive industry and beyond.

2. Zhejiang Xinfeng Machinery Co., Ltd.: Expertise and Innovation in Wheel Hub Casting

At the forefront of Wheel Hub Gravity Casting Mold manufacturing is Zhejiang Xinfeng Machinery Co., Ltd., a subsidiary of Yongfeng Mold Group. With over 380 employees and annual sales exceeding 550 million, Xinfeng is a force to be reckoned with in the industry. The company specializes in aluminum wheel hub and structural casting molds, leveraging its state-of-the-art facilities spanning 30 acres and a 16,000+ square meter plant.

Xinfeng's commitment to customer needs, innovation, and quality is evident in every aspect of its operations. The company annually produces 1,800 sets of molds, each crafted by a team of over 130 skilled professionals, including 30 experienced technicians and designers. Equipped with advanced software tools like CAD, UG, and CATIA, Xinfeng's designers are able to create highly precise and complex mold designs that meet the most demanding specifications. Furthermore, the company has implemented a robust mold production progress system, ensuring timely delivery and consistent quality throughout the production cycle.

3. Advancing Automotive Manufacturing with Wheel Hub Gravity Casting Mold

The versatility of Wheel Hub Gravity Casting Mold extends far beyond the production of automotive wheels. This technique is equally applicable to a wide range of automotive components, including engine parts, brackets, and structural elements. By leveraging the low-cost and high-efficiency benefits of gravity casting, automakers can optimize their production processes, reduce overall costs, and enhance product quality.

Zhejiang Xinfeng Machinery Co., Ltd.'s expertise in Wheel Hub Gravity Casting Mold is a testament to the continued evolution of automotive manufacturing. By staying at the forefront of technological advancements and prioritizing customer needs, Xinfeng is driving the industry forward, crafting precision components that meet the rigorous demands of the modern automotive landscape. With its focus on innovation, quality, and sustainability, Xinfeng is poised to continue leading the way in Wheel Hub Gravity Casting Mold manufacturing for years to come.

English

English 中文简体

中文简体