Precision plays a fundamental role in the production of wheel hub motorcycle casting molds. The wheel hub is a critical component of the motorcycle, responsible for supporting the wheel and ensuring s...

Casting Wheel Hub Air-Cooled Low-Pressure Mold Suppliers

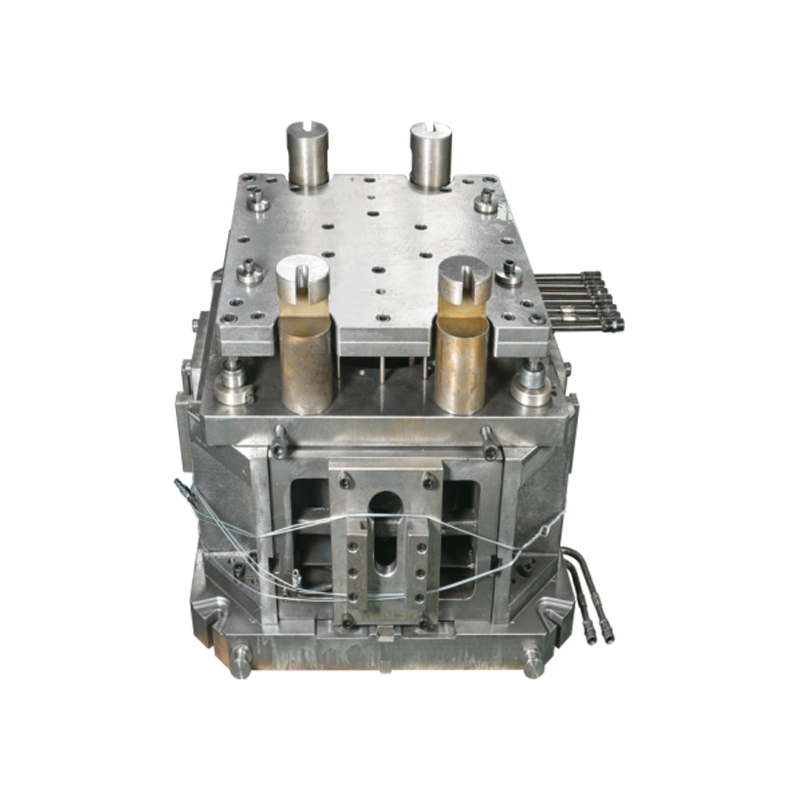

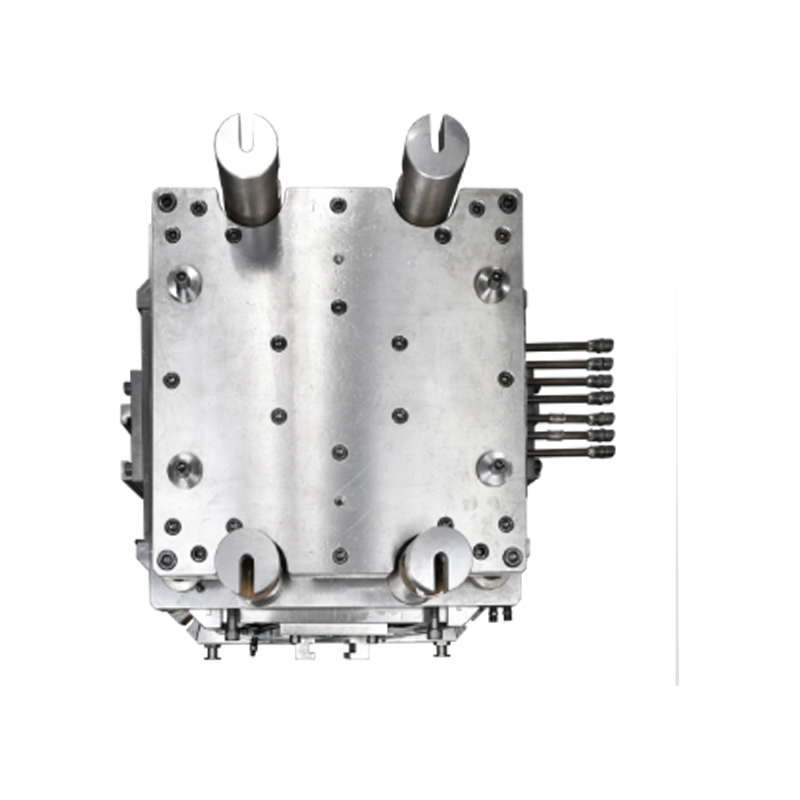

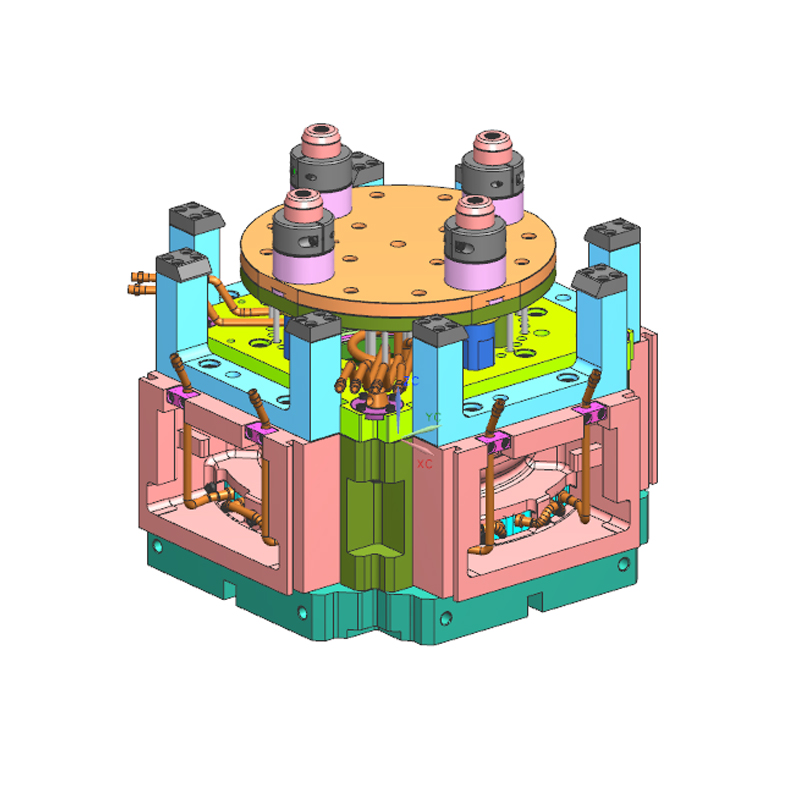

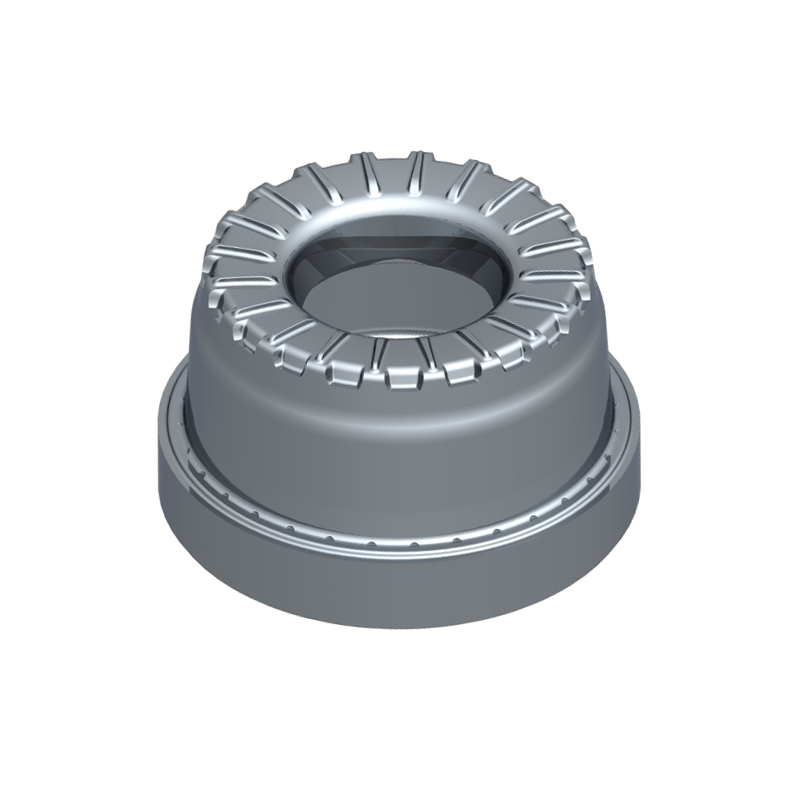

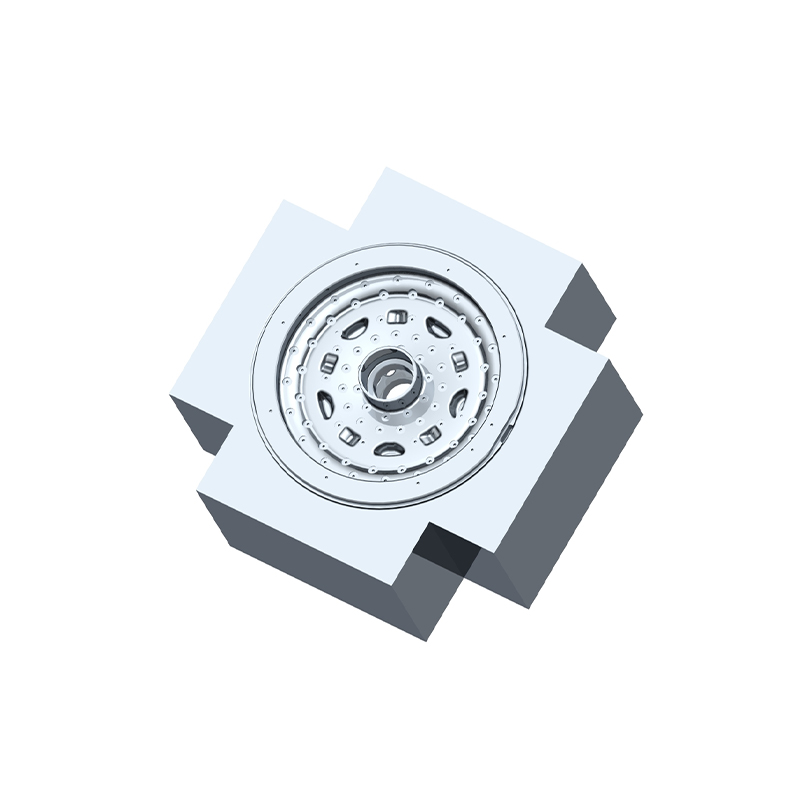

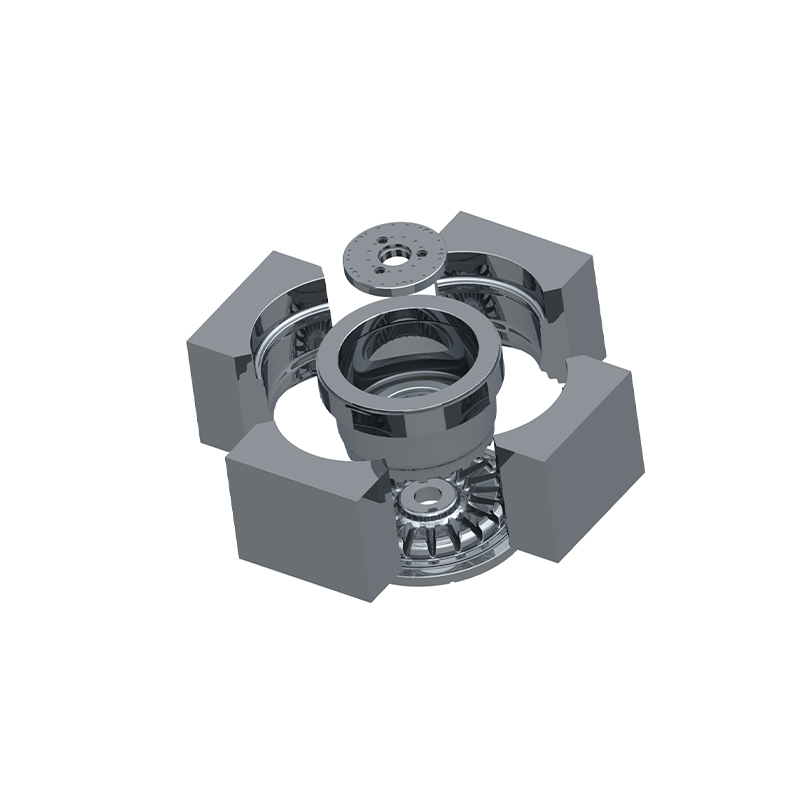

Casting Wheel Hub Air-Cooled Low-Pressure Mold is a low-pressure mold designed for casting wheels. It has a unique air cooling function, which can effectively improve the cooling efficiency and mold life during the casting process. The mold adopts low-pressure casting technology to ensure a smooth surface and uniform structure of the casting, and is suitable for casting aluminum alloys and other alloy materials. The air cooling system avoids casting defects caused by temperature fluctuations by controlling the cooling rate, ensuring that every cast wheel hub meets strict quality standards. This mold is widely used in the manufacturing of wheels for automobiles, motorcycles and other means of transportation, and is particularly suitable for industries that require high precision and high reliability. Our Casting Wheel Hub Air-Cooled Low-Pressure Mold is resistant to high temperatures and corrosion, and can withstand long-term high-load work, ensuring a stable and efficient production process.

Zhejiang Xinfeng Machinery Co., Ltd. is professional China Casting Wheel Hub Air-Cooled Low-Pressure Mold Suppliers and Custom Casting Wheel Hub Air-Cooled Low-Pressure Mold Manufacturers.Zhejiang Xinfeng Machinery and Shengzhou Yuanfeng Mold are subsidiaries of Yongfeng Mold Group, with over 380 employees and annual sales of 550 million. Xinfeng specializes in aluminum wheel hub and structural casting molds, covering 30 acres, with a 16,000+ sqm plant, outputting 1,800 sets of molds annually, employing over 130 staff, including 30 skilled technicians and designers using CAD, UG, CATIA, etc. The company focuses on customer needs, innovation, and quality, implementing a mold production progress system and equipped with advanced machinery like CNC centers.

Yuanfeng Mold Co., Ltd. was established in Yongfeng Group, focusing on mold steel forging products, with multiple forging and electro slag remelting production lines, mainly producing mold raw materials such as H13 series and 35CrMo. The company actively promotes technological innovation and brand innovation, strengthens quality management, enhances corporate image, complies with ISO9001:2015 international quality system standards, and has won the titles of Shengzhou City's "30 Best" Enterprises, Integrity Enterprises, and National High-tech Enterprises.

Xinfeng Machinery actively participates in the "waste-free factory construction" and became a member of the "waste-free factory" in October 2022. It maintains long-term strategic cooperation with nearly 40 wheel hub factories and aluminum casting manufacturers, ranks among the top three in the aluminum alloy casting mold industry, leads the casting process industry, and produces 2,000 sets of molds annually. It is committed to using technology to improve product quality and using craftsmanship to create each product.

-

-

A wheel hub motorcycle casting mold is an essential tool in the manufacturing process of motorcycle wheel hubs. It plays a key role in shaping the molten metal into the precise dimensions required for...

-

A wheel hub differential pressure casting mold is a specialized mold used in the casting process to produce wheel hubs, commonly found in vehicles. The “differential pressure casting” technique involv...

1.What is a Wheel Hub Air-Cooled Low-Pressure Mold and How Does It Work?

A Wheel Hub Air-Cooled Low-Pressure Mold is a specialized casting mold used in the production of automobile wheels, leveraging advanced casting technology to achieve superior results. This mold employs air-cooled low-pressure casting techniques to enhance the quality and efficiency of wheel hub production.

The primary feature of this mold is its integrated air-cooling system, which includes cooling channels or cooling fins situated at the bottom of the mold. During the casting process, molten metal is introduced into the mold under low pressure, allowing for precise control over its flow and filling. As the metal fills the mold, the air-cooling system rapidly dissipates heat, thus accelerating the solidification process.

This rapid cooling is essential for improving casting quality. By quickly and evenly solidifying the metal, the mold helps to reduce defects such as porosity and inclusions, which can compromise the integrity of the final product. The even solidification also ensures that the wheel hub maintains consistent density and structural strength.

The precise control offered by this technology allows for the production of complex and precise wheel hub designs, meeting the high standards required in the automotive industry. Zhejiang Xinfeng Machinery Co., Ltd., a prominent manufacturer in this field, specializes in producing and supplying these advanced molds. Their expertise and customized solutions cater to the specific needs of their clients, ensuring top-quality outcomes.

2.How Does Air Cooling Improve the Quality of Wheel Hub Castings?

The air-cooled low-pressure casting technology employed in wheel hub molds provides several critical advantages that enhance the quality of the castings. One of the most significant benefits is the reduction of internal defects, such as pores and inclusions.

The rapid cooling effect of the air-cooled system is crucial for improving the density and mechanical properties of the casting. As the molten metal solidifies quickly and uniformly, the likelihood of defects like gas bubbles and impurities is minimized. This results in a casting with a more uniform structure and greater durability, essential for high-performance wheel hubs.

Additionally, the air-cooled mold technology allows for precise control over the casting dimensions and surface finish. The rapid solidification helps to maintain the desired shape and size, reducing the need for additional finishing work. This precision is particularly valuable in the automotive sector, where wheel hubs must meet stringent quality and safety standards.

The capability to produce complex and detailed designs is another advantage of air-cooled low-pressure casting. The technology enables the accurate reproduction of intricate features and geometric shapes, ensuring that the final product aligns perfectly with design specifications. Zhejiang Xinfeng Machinery Co., Ltd., with its expertise in air-cooled low-pressure molds, ensures that these technological advantages are realized in the wheel hub manufacturing process, delivering high-quality results to their clients.

3.What Are the Advantages of Using Wheel Hub Air-Cooled Low-Pressure Molds in Automotive Manufacturing?

The use of wheel hub air-cooled low-pressure molds in automotive manufacturing offers numerous advantages that enhance both production efficiency and product quality. Zhejiang Xinfeng Machinery Co., Ltd., a leading supplier in this field, highlights several key benefits of this technology:

Enhanced Production Efficiency: The integration of low-pressure casting with air cooling significantly boosts production efficiency. The rapid cooling process reduces cycle times, allowing for quicker production rates. This efficiency is vital in automotive manufacturing, where high-volume production is often necessary. By shortening solidification times, manufacturers can increase output and reduce lead times, resulting in a more streamlined operation.

Improved Casting Quality: Air-cooled low-pressure molds contribute to superior casting quality by minimizing internal defects and ensuring consistent material properties. The rapid and uniform cooling process helps eliminate porosity and inclusions, producing wheel hubs with high density and strength. This quality enhancement is crucial for meeting the rigorous performance and safety standards required in automotive applications.

English

English 中文简体

中文简体