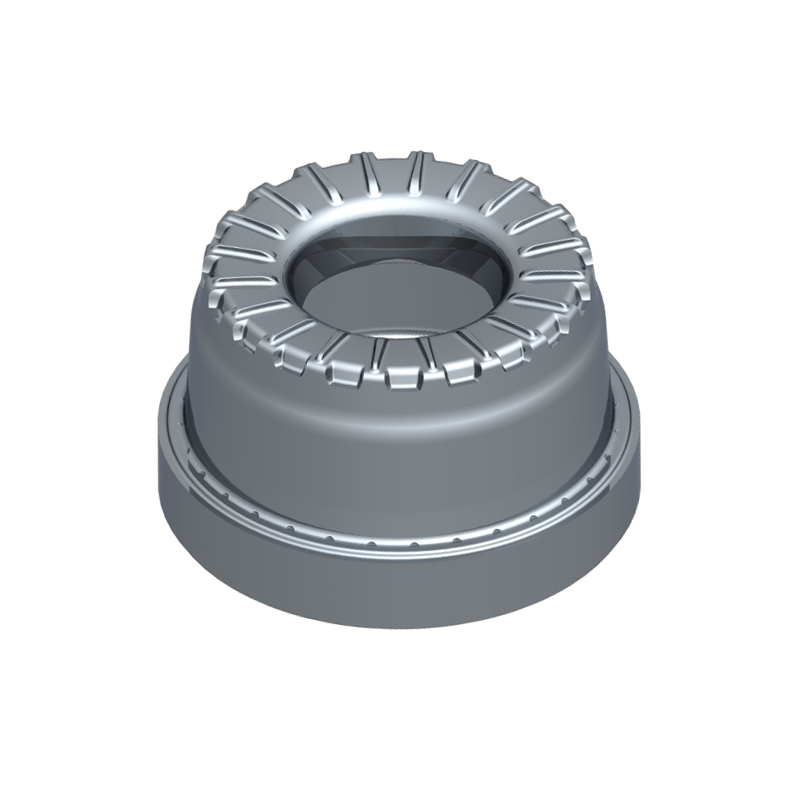

Precision plays a fundamental role in the production of wheel hub motorcycle casting molds. The wheel hub is a critical component of the motorcycle, responsible for supporting the wheel and ensuring s...

Casting Wheel Hub Body Water-Cooled Low-Pressure Mold Suppliers

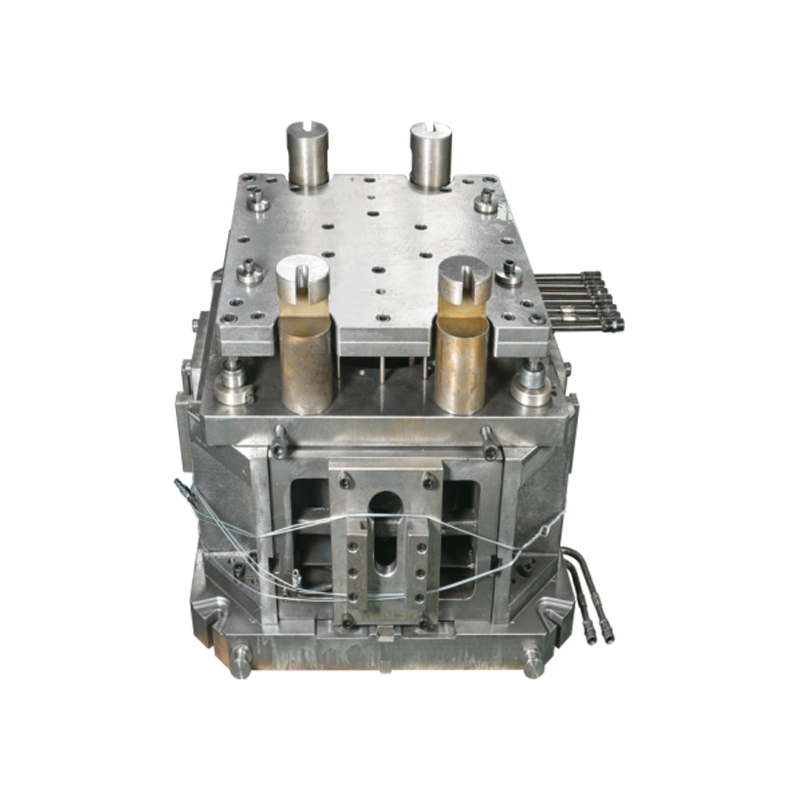

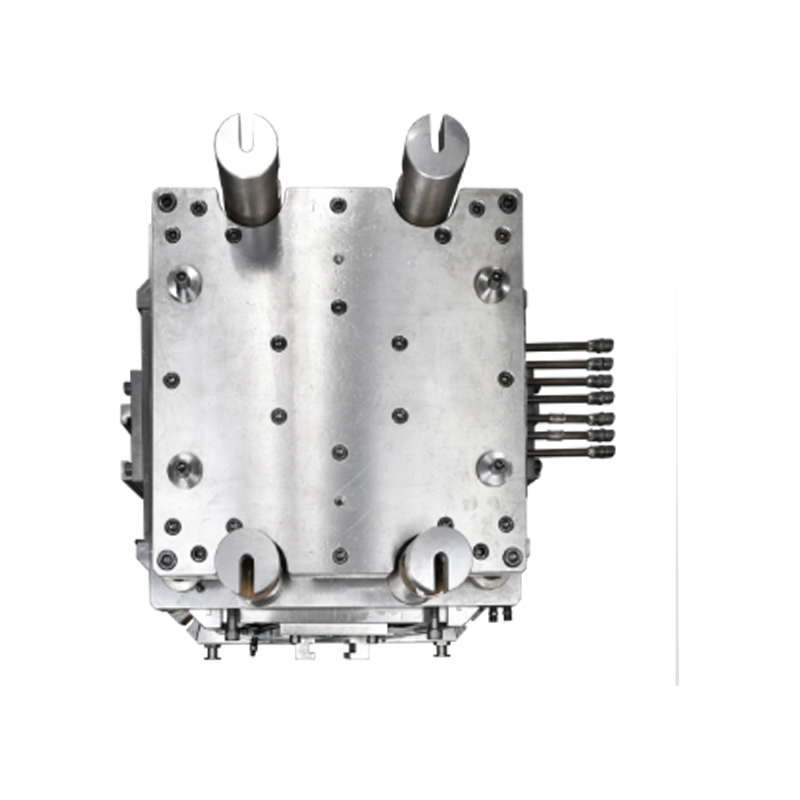

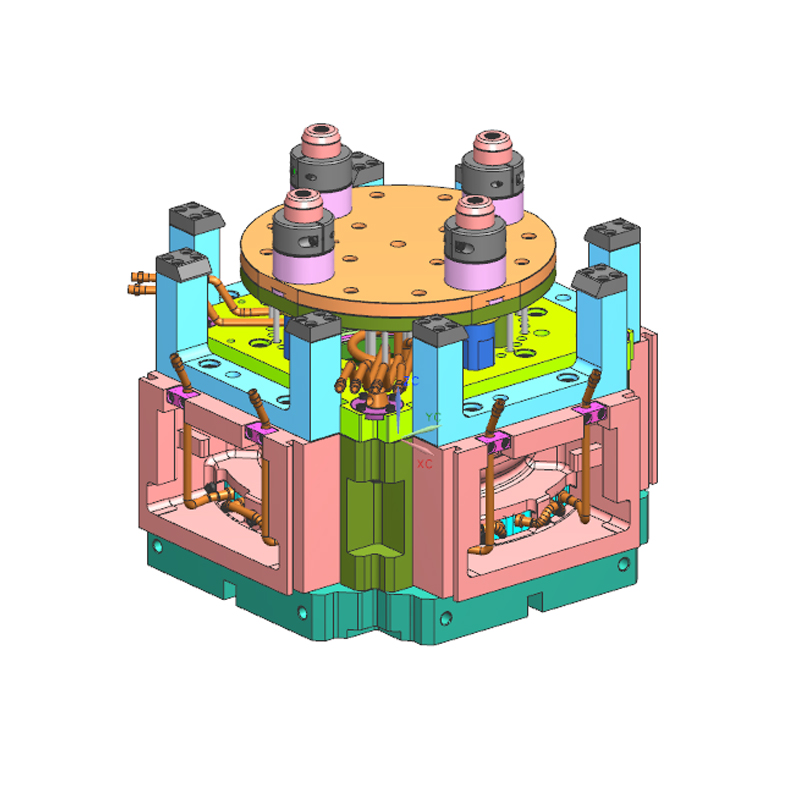

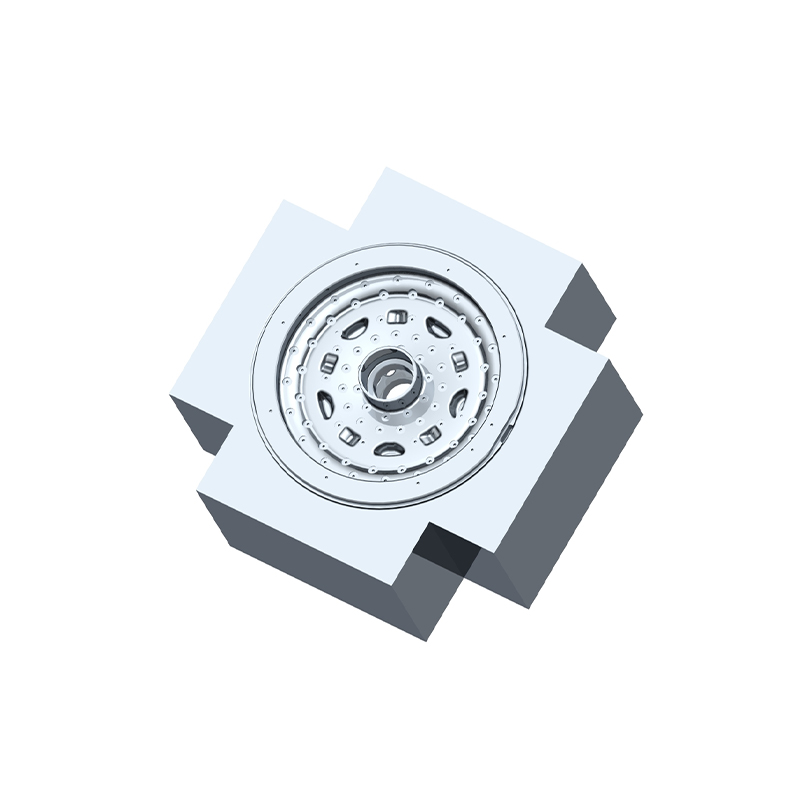

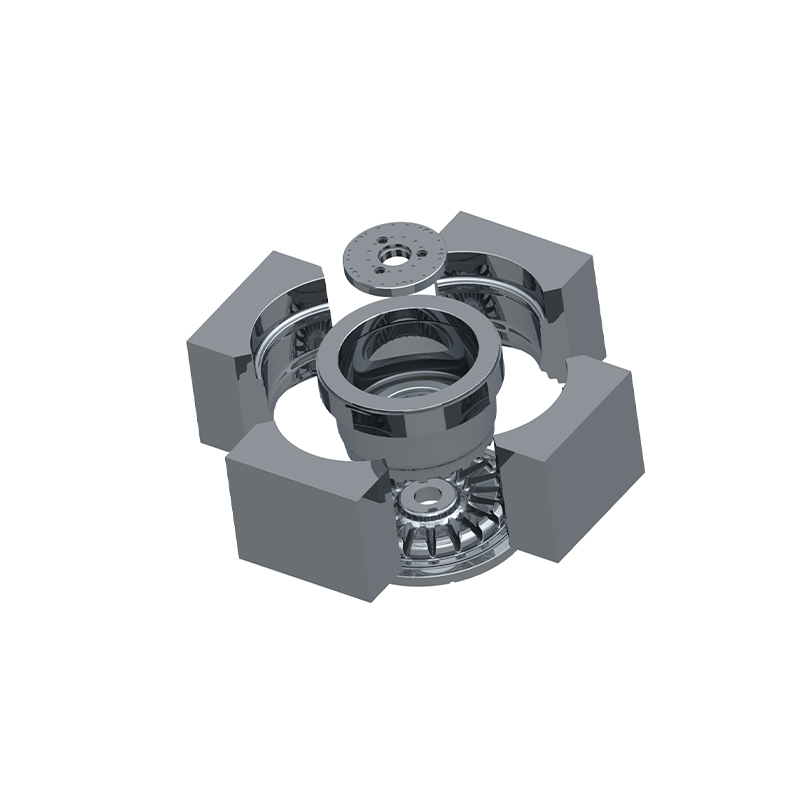

Casting Wheel Hub Body Water-Cooled Low-Pressure Mold adopts advanced low-pressure casting technology and is designed for the production of wheel hub bodies, ensuring high precision, high strength and excellent surface quality of the product. Through the integrated water cooling system, the mold can effectively control the temperature during the casting process, improve production efficiency, and extend the service life of the mold. Our water-cooled low-pressure mold combines low-pressure casting technology with an air cooling system to ensure accurate temperature control during the casting process and avoid casting defects caused by too fast cooling. Its stable performance makes the casting surface smoother and the structure denser, which is suitable for various alloy materials, especially in the automotive and motorcycle industries.

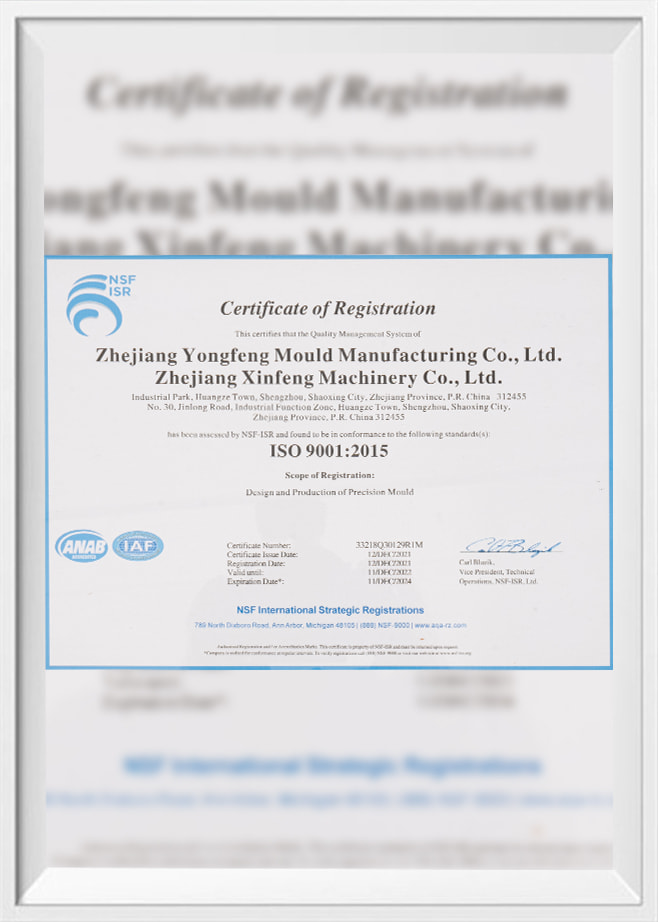

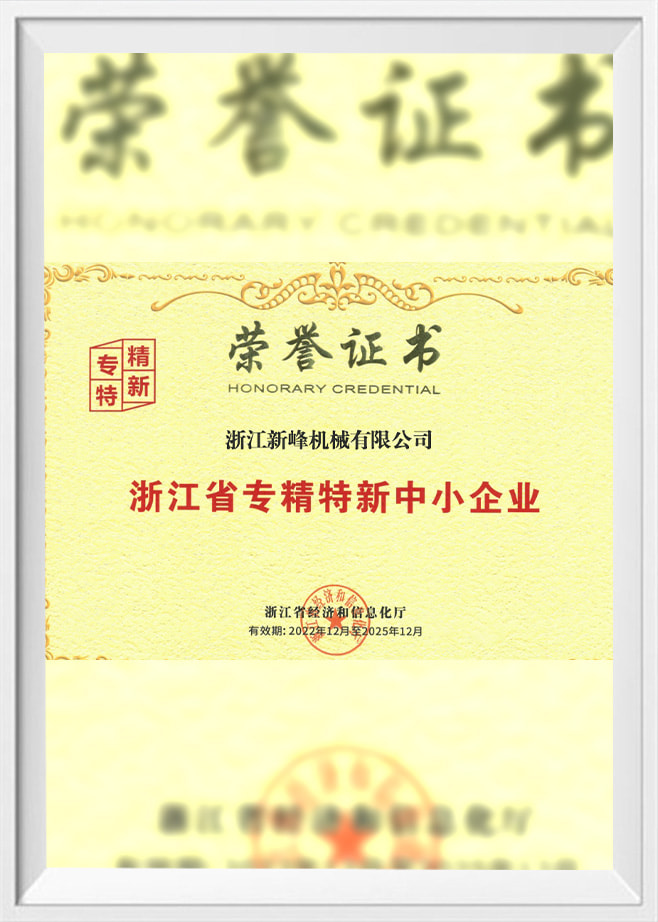

Zhejiang Xinfeng Machinery Co., Ltd. is professional China Casting Wheel Hub Body Water-Cooled Low-Pressure Mold Suppliers and Custom Casting Wheel Hub Body Water-Cooled Low-Pressure Mold Manufacturers.Zhejiang Xinfeng Machinery and Shengzhou Yuanfeng Mold are subsidiaries of Yongfeng Mold Group, with over 380 employees and annual sales of 550 million. Xinfeng specializes in aluminum wheel hub and structural casting molds, covering 30 acres, with a 16,000+ sqm plant, outputting 1,800 sets of molds annually, employing over 130 staff, including 30 skilled technicians and designers using CAD, UG, CATIA, etc. The company focuses on customer needs, innovation, and quality, implementing a mold production progress system and equipped with advanced machinery like CNC centers.

Yuanfeng Mold Co., Ltd. was established in Yongfeng Group, focusing on mold steel forging products, with multiple forging and electro slag remelting production lines, mainly producing mold raw materials such as H13 series and 35CrMo. The company actively promotes technological innovation and brand innovation, strengthens quality management, enhances corporate image, complies with ISO9001:2015 international quality system standards, and has won the titles of Shengzhou City's "30 Best" Enterprises, Integrity Enterprises, and National High-tech Enterprises.

Xinfeng Machinery actively participates in the "waste-free factory construction" and became a member of the "waste-free factory" in October 2022. It maintains long-term strategic cooperation with nearly 40 wheel hub factories and aluminum casting manufacturers, ranks among the top three in the aluminum alloy casting mold industry, leads the casting process industry, and produces 2,000 sets of molds annually. It is committed to using technology to improve product quality and using craftsmanship to create each product.

-

-

A wheel hub motorcycle casting mold is an essential tool in the manufacturing process of motorcycle wheel hubs. It plays a key role in shaping the molten metal into the precise dimensions required for...

-

A wheel hub differential pressure casting mold is a specialized mold used in the casting process to produce wheel hubs, commonly found in vehicles. The “differential pressure casting” technique involv...

1. How to choose the right Casting Wheel Hub Body Water-Cooled Low-Pressure Mold?

Zhejiang Xinfeng Machinery Co., Ltd. is your trusted partner when looking for a water-cooled low-pressure mold for casting hub body that suits your production needs. Choosing the right mold is a key step to ensure a smooth casting process. The right mold not only improves production efficiency, but also guarantees the quality and performance of the final product. Our mold design team has many years of experience in casting technology and is committed to providing customers with high-quality solutions.

You need to understand the material and structure of the mold. High-quality water-cooled low-pressure molds for casting hub body should be made of high-temperature and wear-resistant materials to ensure stable operation under high load and high temperature environments. Zhejiang Xinfeng Machinery Co., Ltd.'s molds use advanced casting technology and high-strength alloy materials, have excellent durability and heat resistance, and can adapt to various complex casting needs.

It is crucial to consider the cooling system of the mold. Water-cooled low-pressure molds require an efficient cooling system to ensure that the metal liquid is quickly cooled during the casting process and reduce casting defects. Our molds are equipped with an efficient water cooling system that can evenly distribute cooling water and quickly take away excess heat, thereby improving casting quality and production efficiency.

Choosing a reliable supplier is also key. Zhejiang Xinfeng Machinery Co., Ltd. has a complete after-sales service system, which can provide technical support and maintenance services during your use. Our professional team will provide customized mold solutions according to your production needs, and provide full technical support during production and use.

2.What unique advantages can Zhejiang Xinfeng Machinery Co., Ltd.’s molds provide?

When choosing a water-cooled low-pressure mold for cast hub bodies, it is critical to understand its unique advantages. Zhejiang Xinfeng Machinery Co., Ltd.'s molds have obvious competitive advantages in the industry and can bring many significant benefits to customers. These advantages are not only reflected in the performance of the mold, but also include its overall improvement in production efficiency and product quality.

Our molds use the latest casting technology and materials. Zhejiang Xinfeng Machinery Co., Ltd. uses high-strength alloy materials and precision processing technology to ensure that the mold has excellent wear resistance and high temperature resistance. This material selection not only extends the service life of the mold, but also maintains stable performance under high-load working conditions, reducing production shutdowns and maintenance costs caused by mold wear.

Our water cooling system design offers unique advantages. The cooling system of the mold is one of the key factors affecting casting quality. Zhejiang Xinfeng Machinery Co., Ltd. uses advanced water cooling technology to achieve uniform and stable cooling effects and avoid casting defects caused by uneven cooling. This efficient cooling system not only improves the quality of cast products, but also shortens the production cycle and improves production efficiency.

The molds provided by Zhejiang Xinfeng Machinery Co., Ltd. also have good compatibility and flexibility. We can provide tailor-made mold solutions based on customers' specific needs. This customized service can ensure that the mold is perfectly matched with the customer's production equipment and process flow, thereby achieving higher production efficiency and better product quality.

Our product quality control and after-sales service are also a big advantage. Zhejiang Xinfeng Machinery Co., Ltd. has a strict quality inspection system and a professional after-sales team, which can conduct all-round quality monitoring during the production process and provide timely technical support and maintenance services during use. This comprehensive service system can ensure the long-term stable operation of the mold and help customers solve various problems encountered during use.

3. How to ensure the long-term reliability of the Casting Wheel Hub Body Water-Cooled Low-Pressure Mold?

Ensuring the long-term reliability of the water-cooled low-pressure mold for casting wheel hub body is a crucial link in any production process. Zhejiang Xinfeng Machinery Co., Ltd. is committed to providing high-reliability products in the design, production and maintenance of molds to ensure the production stability and economic benefits of customers.

The material and process of the mold determine its reliability in long-term use. Zhejiang Xinfeng Machinery Co., Ltd.'s water-cooled low-pressure mold for casting wheel hub body uses high-quality alloy materials, which have excellent wear resistance and high temperature resistance. We also use advanced casting process and heat treatment technology to ensure that the mold will not suffer excessive wear or performance degradation during long-term use. This high-standard manufacturing process can effectively extend the service life of the mold and reduce production interruptions and maintenance costs caused by mold damage.

The design and maintenance of the mold also play an important role in its long-term reliability. Zhejiang Xinfeng Machinery Co., Ltd. fully considers the efficiency of the cooling system and the durability of the mold structure during the mold design process. The molds we provide are equipped with an efficient water cooling system, which can quickly and evenly cool the cast products, avoiding casting defects caused by uneven cooling. In addition, we also provide detailed use and maintenance guides to help customers use and maintain the mold correctly, thereby extending its service life.

Regular inspection and maintenance are also important measures to ensure the long-term reliability of the mold. The molds provided by Zhejiang Xinfeng Machinery Co., Ltd. will undergo strict quality inspections before delivery to ensure that their performance meets the highest standards. During use, we recommend that customers regularly check the wear of the mold and the working status of the cooling system, and perform necessary maintenance and repairs as needed. We also provide professional technical support to help customers solve problems encountered during use.

English

English 中文简体

中文简体