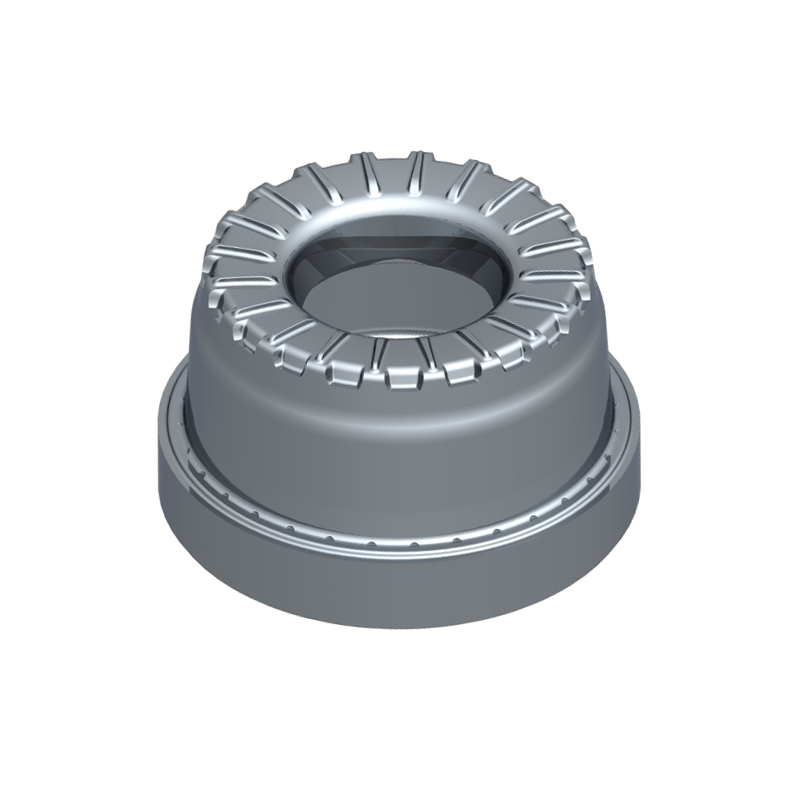

Precision plays a fundamental role in the production of wheel hub motorcycle casting molds. The wheel hub is a critical component of the motorcycle, responsible for supporting the wheel and ensuring s...

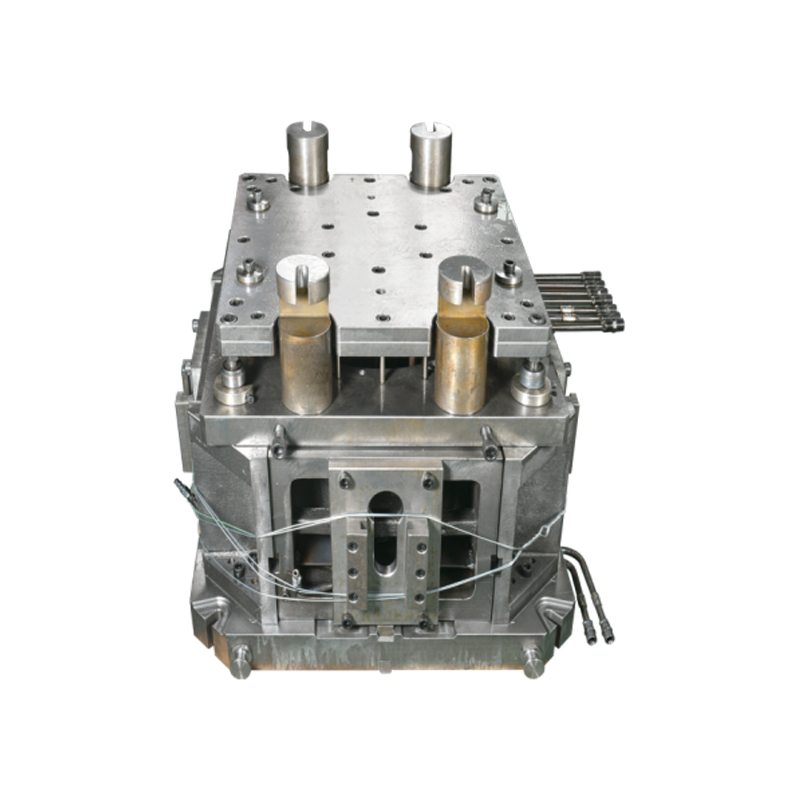

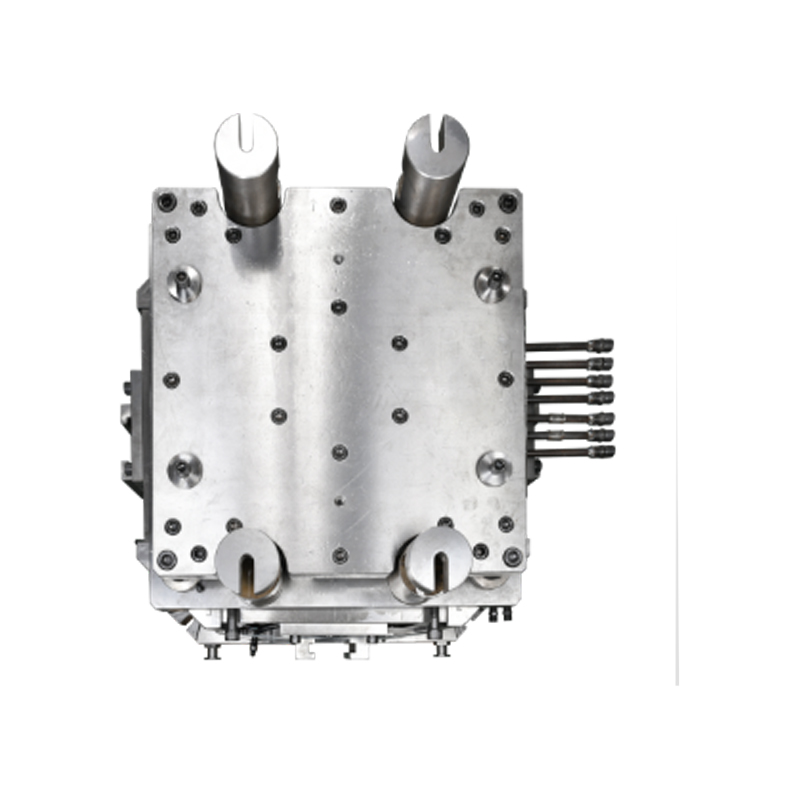

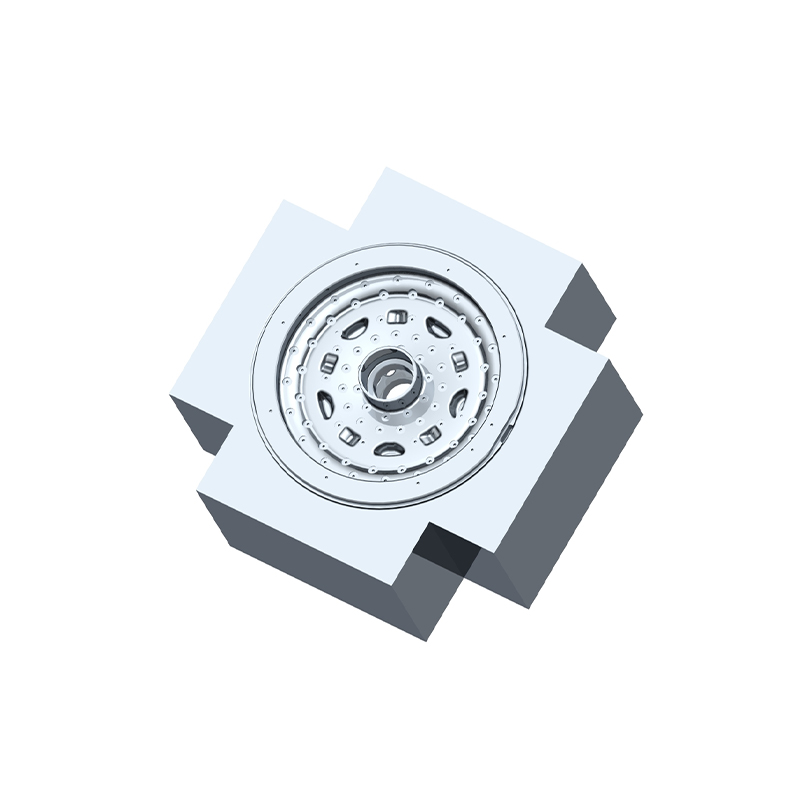

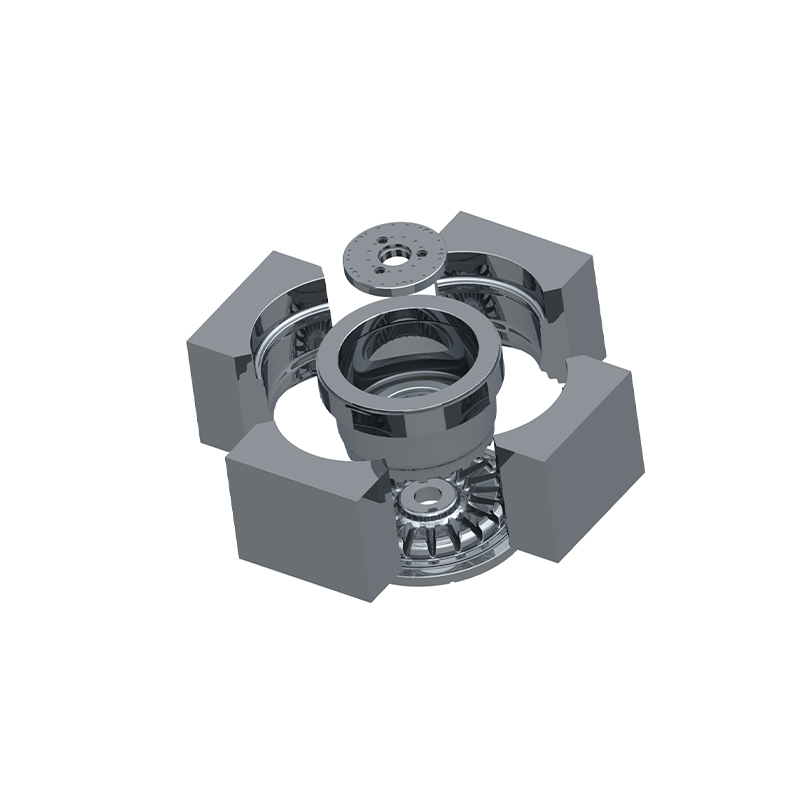

Casting Wheel Hub Point-Type Water-Cooled Low-Pressure Mold Suppliers

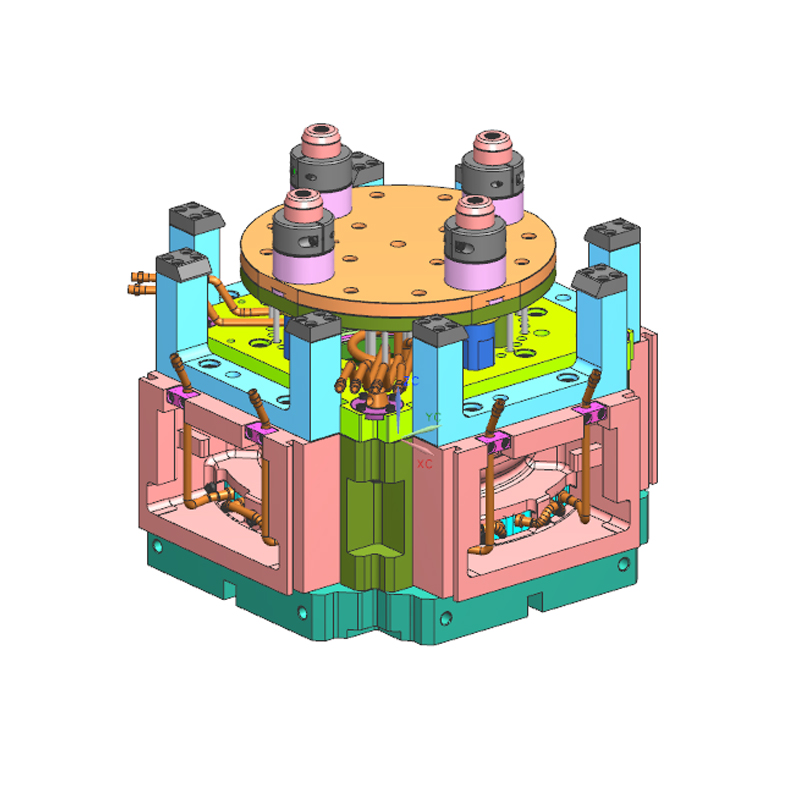

Casting Wheel Hub Point-Type Water-Cooled Low-Pressure Mold is a type of advanced mold specially designed for high-performance wheel hub manufacturing. This type of mold combines point water cooling technology with low-pressure casting technology. The precision cooling system inside the mold adopts point water cooling design. By accurately controlling the layout of cooling points and the flow of coolant, it achieves efficient and uniform control of the mold temperature. . This design not only significantly increases the solidification speed of the molten metal and ensures the optimal microstructure and mechanical properties of the wheel hub, but also effectively avoids problems such as deformation and cracking caused by overheating of the mold, thereby greatly improving the product's quality. Yield and consistency. The application of low-pressure casting technology allows the molten metal to slowly fill the mold under lower pressure, reducing the involvement of gas and inclusions, and further improving the compactness and surface quality of the wheel hub. The combination of this process with point-type water-cooled molds enables the production of wheel hubs with higher strength, better toughness and longer service life. Casting Wheel Hub Point-Type Water-Cooled Low-Pressure Mold also offers the advantages of easy maintenance and simple operation. The cooling system of the mold adopts a modular design, which facilitates cleaning and maintenance, reducing production costs and downtime.

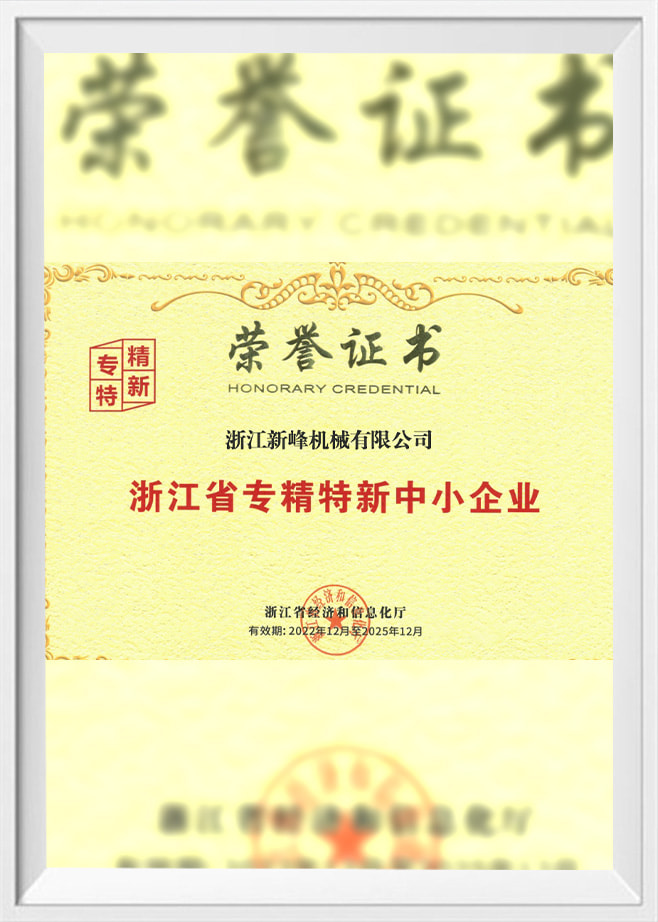

Zhejiang Xinfeng Machinery Co., Ltd. is professional China Casting Wheel Hub Point-Type Water-Cooled Low-Pressure Mold Suppliers and Custom Casting Wheel Hub Point-Type Water-Cooled Low-Pressure Mold Manufacturers.Zhejiang Xinfeng Machinery and Shengzhou Yuanfeng Mold are subsidiaries of Yongfeng Mold Group, with over 380 employees and annual sales of 550 million. Xinfeng specializes in aluminum wheel hub and structural casting molds, covering 30 acres, with a 16,000+ sqm plant, outputting 1,800 sets of molds annually, employing over 130 staff, including 30 skilled technicians and designers using CAD, UG, CATIA, etc. The company focuses on customer needs, innovation, and quality, implementing a mold production progress system and equipped with advanced machinery like CNC centers.

Yuanfeng Mold Co., Ltd. was established in Yongfeng Group, focusing on mold steel forging products, with multiple forging and electro slag remelting production lines, mainly producing mold raw materials such as H13 series and 35CrMo. The company actively promotes technological innovation and brand innovation, strengthens quality management, enhances corporate image, complies with ISO9001:2015 international quality system standards, and has won the titles of Shengzhou City's "30 Best" Enterprises, Integrity Enterprises, and National High-tech Enterprises.

Xinfeng Machinery actively participates in the "waste-free factory construction" and became a member of the "waste-free factory" in October 2022. It maintains long-term strategic cooperation with nearly 40 wheel hub factories and aluminum casting manufacturers, ranks among the top three in the aluminum alloy casting mold industry, leads the casting process industry, and produces 2,000 sets of molds annually. It is committed to using technology to improve product quality and using craftsmanship to create each product.

-

-

A wheel hub motorcycle casting mold is an essential tool in the manufacturing process of motorcycle wheel hubs. It plays a key role in shaping the molten metal into the precise dimensions required for...

-

A wheel hub differential pressure casting mold is a specialized mold used in the casting process to produce wheel hubs, commonly found in vehicles. The “differential pressure casting” technique involv...

1. Advanced Cooling Technology: Enhancing Casting Quality

The point-type water-cooled low-pressure mold represents a breakthrough in the field of casting technology, specifically tailored for the production of automobile wheel hubs. This mold employs a cutting-edge cooling mechanism that enhances the overall quality of the cast product. Unlike traditional casting methods, which often rely on more generalized cooling techniques, this mold features a precise point water-cooling system. This system is designed to target specific areas of the mold with controlled water flows, utilizing small holes or channels strategically placed within the mold.

The primary advantage of this advanced cooling technology is its ability to regulate the cooling rate and solidification process of the metal more effectively. By directing water precisely where it is needed, the mold can achieve a more uniform cooling rate across different regions of the casting. This precision helps to mitigate common casting defects such as porosity, which occurs when gas bubbles become trapped within the solidifying metal, or inclusions, which are foreign particles embedded within the metal. Both defects can compromise the structural integrity and performance of the wheel hub.

The targeted cooling process enhances the density and mechanical properties of the cast wheel hub. With a more controlled solidification process, the metal forms a more consistent microstructure, leading to improved strength and durability of the final product. This is particularly important in automotive applications, where wheel hubs must endure significant stress and strain during operation. By reducing internal defects and improving material properties, the point-type water-cooled low-pressure mold ensures that the wheel hubs meet stringent quality standards and perform reliably under demanding conditions.

2. Efficiency and Cost-Effectiveness: Benefits Over Traditional Methods

The Casting Wheel Hub Point-Type Water-Cooled Low-Pressure Mold offers considerable benefits in terms of efficiency and cost-effectiveness compared to traditional cooling methods. Traditional casting techniques often involve more generalized cooling processes that do not adequately address the specific needs of different regions of the mold. This can result in uneven cooling rates, longer solidification times, and increased likelihood of defects, all of which contribute to higher production costs and lower overall efficiency.

The point water cooling system integrated into these molds allows for a more controlled and accelerated solidification process. By targeting specific areas of the mold with precise water flows, the system ensures that the metal cools rapidly and evenly. This not only speeds up the overall production cycle but also reduces the likelihood of defects that can necessitate costly rework or scrapping of defective parts. As a result, manufacturers can achieve higher throughput and better utilization of their production resources.

The enhanced efficiency of the point-type water-cooled low-pressure mold translates into significant cost savings. Faster solidification times mean that production cycles are shortened, allowing for more efficient use of equipment and labor. Additionally, the reduced incidence of defects decreases the need for costly inspections and repairs. The combination of these factors leads to lower manufacturing costs and improved profitability for producers.

The cost-effectiveness of this mold technology is further supported by its ability to maintain consistent quality and reduce waste. By minimizing defects and ensuring a higher yield of usable parts, manufacturers can maximize their return on investment. This makes the point-type water-cooled low-pressure mold an attractive option for companies seeking to optimize their casting operations and achieve a competitive edge in the market.

3. Versatility and Adaptability: Meeting Diverse Production Needs

One of the most compelling advantages of the point-type water-cooled low-pressure mold is its remarkable versatility and adaptability. This mold technology is designed to handle a wide range of wheel hub types, sizes, shapes, and complex structures, making it highly suitable for various applications in the automotive industry. The ability to accommodate diverse casting requirements allows manufacturers to produce a broad spectrum of wheel hub designs with ease.

The adaptability of the mold is particularly valuable in a dynamic and evolving automotive market, where the demand for different wheel hub specifications can vary significantly. Whether manufacturing standard wheel hubs for common vehicle models or producing specialized components for high-performance or custom applications, the point-type water-cooled low-pressure mold provides the flexibility needed to meet these diverse production needs.

In addition to its adaptability in terms of product types, the mold also offers flexibility in production volumes. It is capable of handling both large-scale manufacturing runs and smaller, customized production batches. This versatility makes it an ideal choice for manufacturers who need to balance high-volume production with the ability to quickly respond to changes in market demand or customer specifications.

The mold's design allows for easy integration into existing production lines, minimizing the need for extensive modifications or additional investments in equipment. This ease of integration enhances the overall efficiency of the production process and supports a seamless transition to the new technology.

English

English 中文简体

中文简体