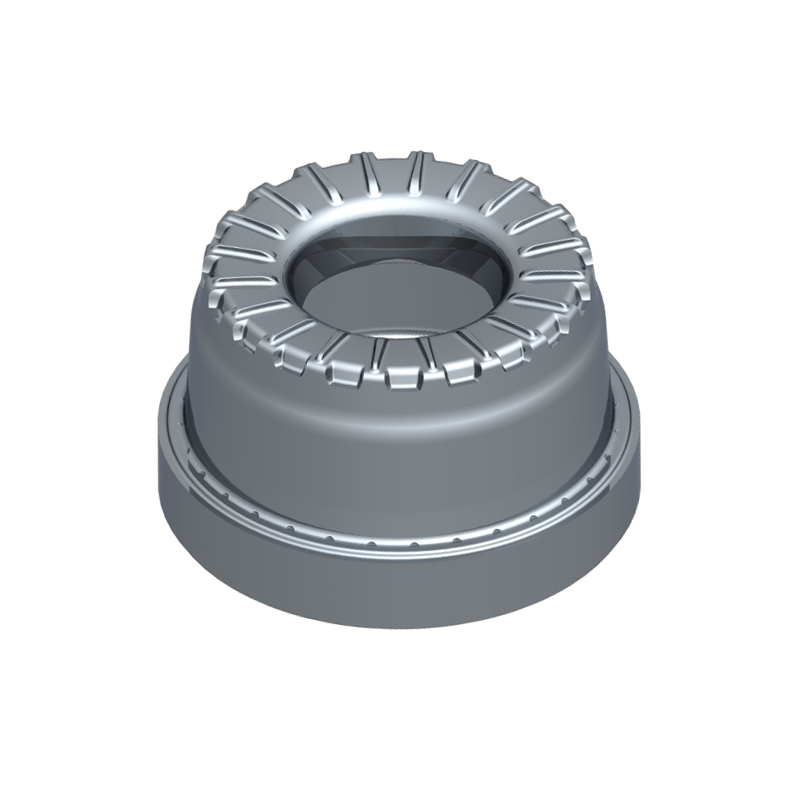

Precision plays a fundamental role in the production of wheel hub motorcycle casting molds. The wheel hub is a critical component of the motorcycle, responsible for supporting the wheel and ensuring s...

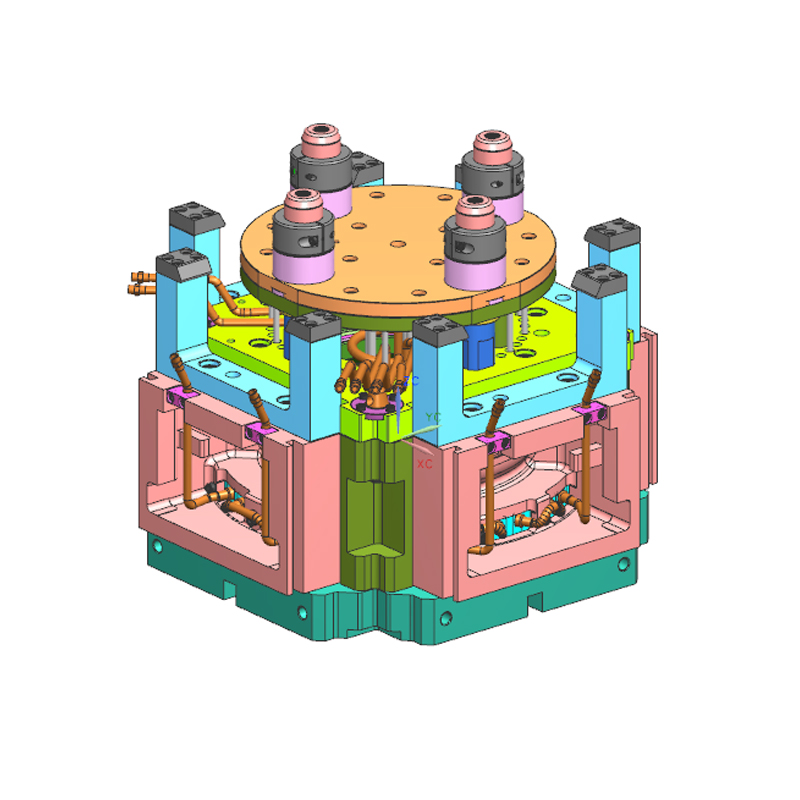

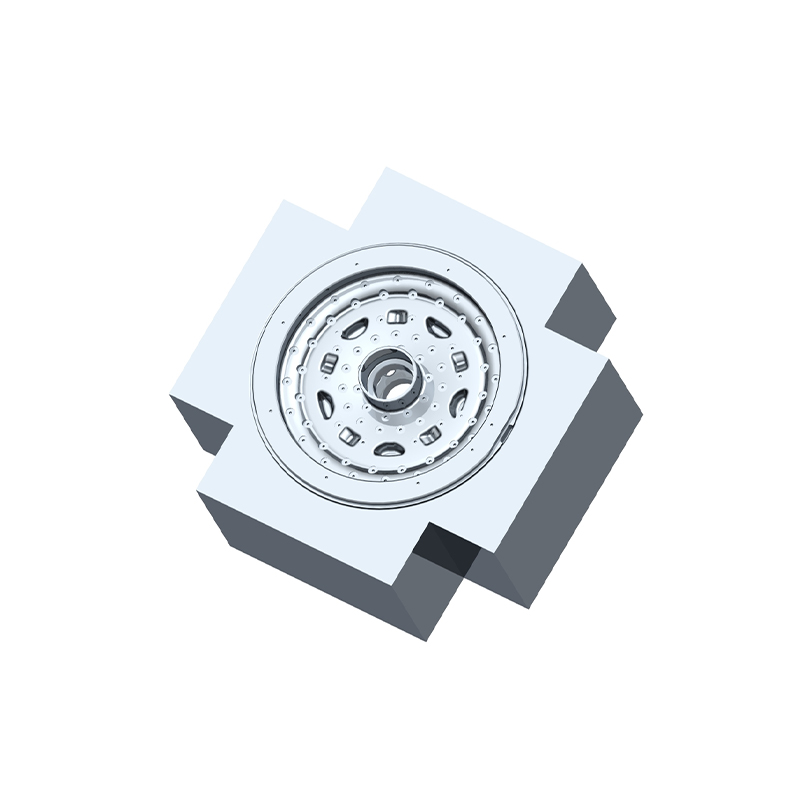

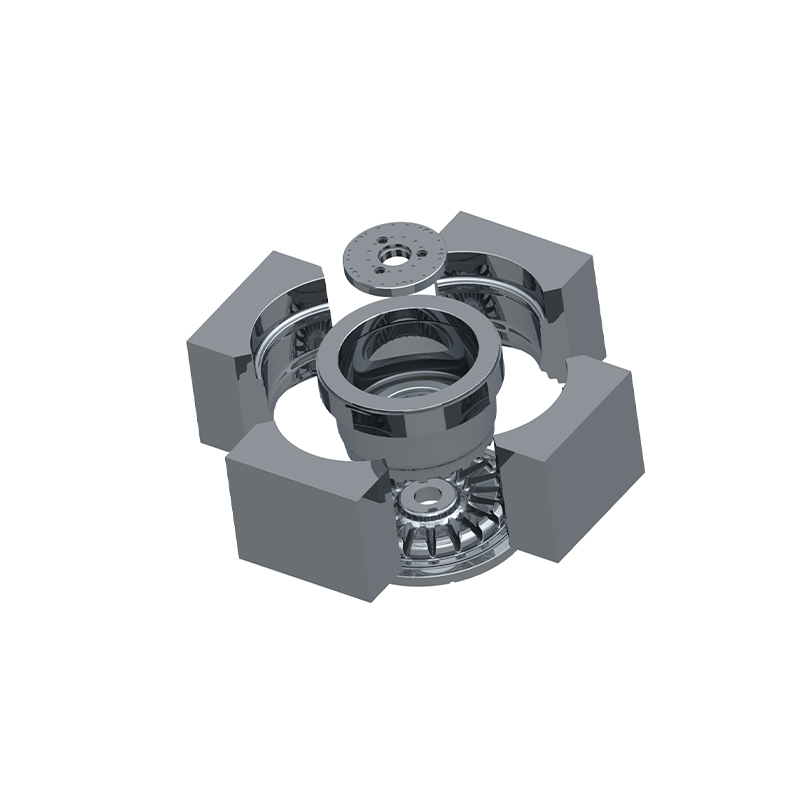

Casting Wheel Hub Water Mist-Cooled Low-Pressure Mold Suppliers

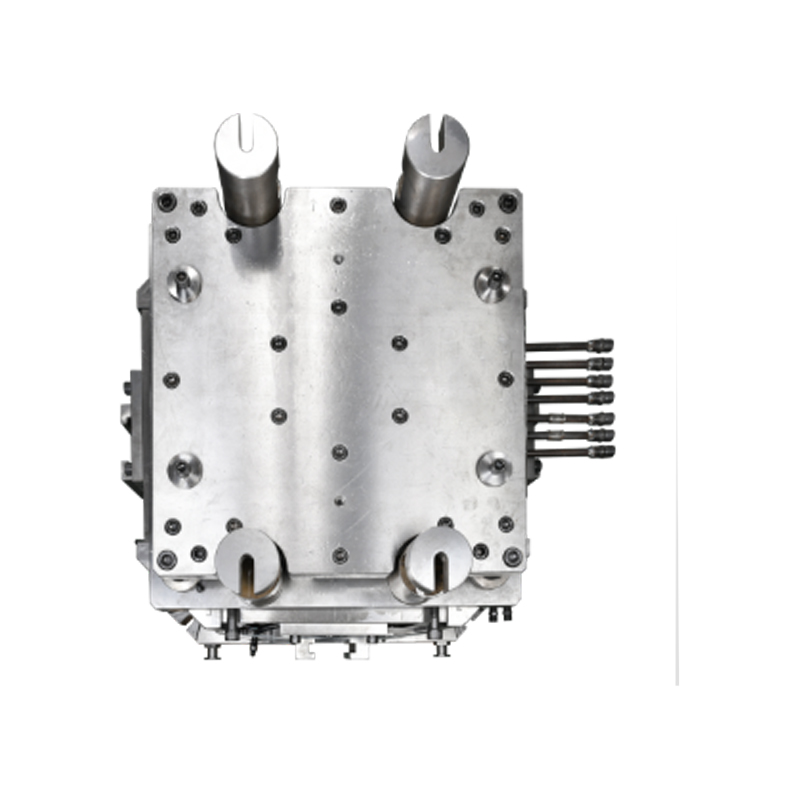

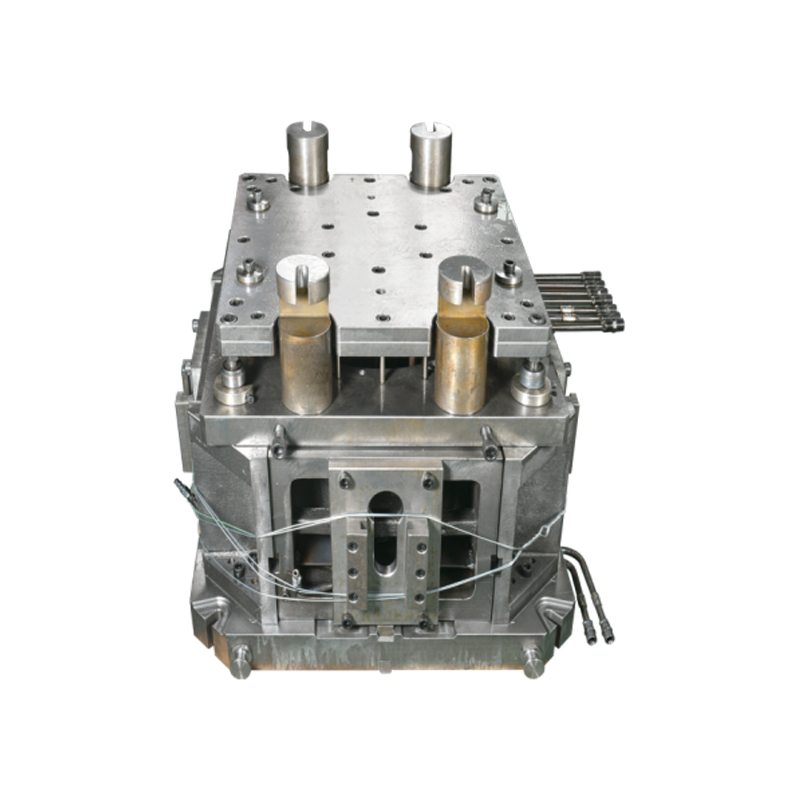

Wheel hub water mist-cooled low-pressure mold is a casting mold specially used for automobile wheel hub manufacturing, which adopts advanced water mist cooling low-pressure casting technology. This mold sprays tiny water mist particles on the surface of molten metal through high-pressure nozzles or micro nozzles during the casting process to quickly cool and solidify the casting. A special water mist cooling system is designed inside the mold, which can accurately spray fine water mist particles onto the surface of the casting to quickly absorb and take away the heat of the molten metal. Water mist cooling technology can achieve a faster and more uniform cooling process of the casting, which helps to reduce thermal stress and metal grain growth, thereby improving the density and mechanical properties of the casting. Compared with traditional cooling methods, water mist cooling low-pressure casting has lower energy consumption reduces the use of cooling medium, and has good environmental friendliness. Wheel hub water mist-cooled low-pressure mold is suitable for various types of automobile wheel hub manufacturing, especially in applications requiring high quality, complex structure, and precision casting. It is widely used in the production of wheels for various types of vehicles such as light vehicles, commercial vehicles, and high-performance racing cars.

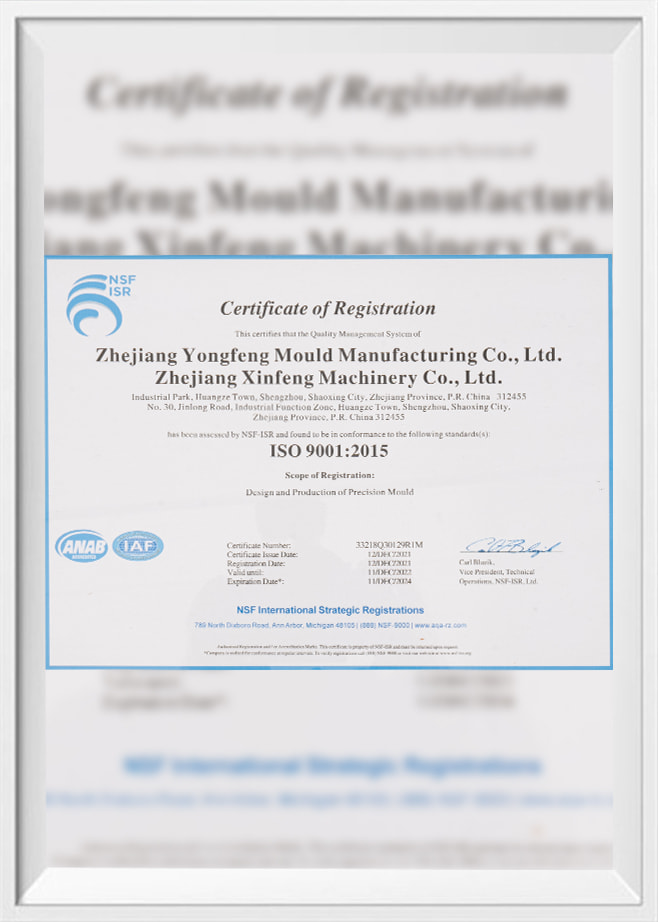

Zhejiang Xinfeng Machinery Co., Ltd. is professional China Casting Wheel Hub Water Mist-Cooled Low-Pressure Mold Suppliers and Custom Casting Wheel Hub Water Mist-Cooled Low-Pressure Mold Manufacturers.Zhejiang Xinfeng Machinery and Shengzhou Yuanfeng Mold are subsidiaries of Yongfeng Mold Group, with over 380 employees and annual sales of 550 million. Xinfeng specializes in aluminum wheel hub and structural casting molds, covering 30 acres, with a 16,000+ sqm plant, outputting 1,800 sets of molds annually, employing over 130 staff, including 30 skilled technicians and designers using CAD, UG, CATIA, etc. The company focuses on customer needs, innovation, and quality, implementing a mold production progress system and equipped with advanced machinery like CNC centers.

Yuanfeng Mold Co., Ltd. was established in Yongfeng Group, focusing on mold steel forging products, with multiple forging and electro slag remelting production lines, mainly producing mold raw materials such as H13 series and 35CrMo. The company actively promotes technological innovation and brand innovation, strengthens quality management, enhances corporate image, complies with ISO9001:2015 international quality system standards, and has won the titles of Shengzhou City's "30 Best" Enterprises, Integrity Enterprises, and National High-tech Enterprises.

Xinfeng Machinery actively participates in the "waste-free factory construction" and became a member of the "waste-free factory" in October 2022. It maintains long-term strategic cooperation with nearly 40 wheel hub factories and aluminum casting manufacturers, ranks among the top three in the aluminum alloy casting mold industry, leads the casting process industry, and produces 2,000 sets of molds annually. It is committed to using technology to improve product quality and using craftsmanship to create each product.

-

-

A wheel hub motorcycle casting mold is an essential tool in the manufacturing process of motorcycle wheel hubs. It plays a key role in shaping the molten metal into the precise dimensions required for...

-

A wheel hub differential pressure casting mold is a specialized mold used in the casting process to produce wheel hubs, commonly found in vehicles. The “differential pressure casting” technique involv...

1.Advanced Water Mist Cooling Technology

The Casting Wheel Hub Water Mist-Cooled Low-Pressure Mold represents a groundbreaking advancement in casting technology, particularly tailored for the production of automobile wheel hubs. This innovative mold, developed by Zhejiang Xinfeng Machinery Co., Ltd., utilizes an advanced water mist cooling system to optimize the casting process. Unlike traditional cooling methods that rely on ambient air or direct water cooling, this mold incorporates a sophisticated mechanism that sprays ultra-fine water mist particles directly onto the molten metal during the casting process.

The core of this technology lies in its precise cooling system, which uses high-pressure or micro nozzles to generate a fine mist of water. This mist is strategically directed onto the surface of the molten metal within the mold. The primary function of this water mist is to rapidly absorb and remove the heat from the molten metal, facilitating a more controlled and uniform solidification process. By employing this method, the mold ensures that the temperature of the molten metal is consistently managed throughout the casting cycle, which is crucial for achieving high-quality castings.

One of the significant advantages of this technology is its ability to enhance the cooling rate of the casting. Traditional cooling methods often result in uneven cooling, which can lead to defects such as warping or internal stresses in the final product. The water mist cooling technology, however, provides a more even and accelerated cooling effect, reducing the likelihood of such defects. This rapid cooling is particularly beneficial for complex and intricate casting designs, as it ensures that all areas of the mold are uniformly cooled, preventing issues related to differential cooling rates.

2.Benefits Over Traditional Cooling Methods

The shift from traditional cooling methods to the advanced water mist cooling technology used in the Wheel Hub Water Mist-Cooled Low-Pressure Mold brings with it a host of benefits that significantly enhance the casting process. This innovative technology, developed by Zhejiang Xinfeng Machinery Co., Ltd., offers several advantages over conventional cooling techniques, making it a preferred choice for high-quality wheel hub production.

One of the most notable benefits of water mist cooling is its ability to reduce thermal stress and control metal grain growth during the casting process. Traditional cooling methods often involve less precise cooling techniques, such as air cooling or direct water contact, which can lead to uneven cooling rates and thermal gradients within the casting. These inconsistencies can result in increased thermal stress and larger metal grains, negatively impacting the mechanical properties of the final product. In contrast, the water mist cooling system provides a more uniform and controlled cooling environment, which minimizes thermal stress and ensures a finer, more consistent metal grain structure. This results in castings with enhanced strength, durability, and overall mechanical performance.

Another significant advantage of water mist cooling technology is its energy efficiency. Traditional cooling methods typically require substantial amounts of water or air to achieve the desired cooling effect, which can lead to higher energy consumption and increased production costs. The water mist system, however, uses a fine mist of water that requires less cooling medium and energy to achieve effective cooling. This reduction in energy consumption not only lowers operational costs but also makes the process more environmentally friendly. By minimizing the use of cooling mediums and reducing energy requirements, the water mist cooling technology aligns with contemporary sustainability goals and reduces the environmental impact of the casting process.

The improved cooling efficiency also contributes to a more precise and accurate casting process. With traditional methods, variations in cooling rates can lead to inconsistencies in the final product, such as dimensional inaccuracies or surface defects. The water mist cooling system, with its precise control over cooling rates, ensures that the casting is uniformly cooled and solidified, resulting in a higher-quality finished product with fewer defects. This level of precision is particularly important for manufacturing high-performance wheel hubs, where exacting standards and tolerances must be met.

3.Versatile Applications in Wheel Hub Manufacturing

The Casting Wheel Hub Water Mist-Cooled Low-Pressure Mold, developed by Zhejiang Xinfeng Machinery Co., Ltd., is designed to cater to a wide range of applications in automobile wheel hub manufacturing. This versatile mold is suitable for producing wheel hubs for various types of vehicles, including light vehicles, commercial trucks, and high-performance racing cars. Its advanced cooling technology and precision casting capabilities make it an ideal choice for meeting the diverse demands of the automotive industry.

One of the key applications of this mold is in the production of high-quality wheel hubs for light vehicles. These vehicles, which include passenger cars and SUVs, require wheel hubs that meet stringent performance and safety standards. The water mist cooling technology ensures that the wheel hubs are cast with a high degree of precision and consistency, resulting in components that exhibit excellent mechanical properties and durability. This is crucial for light vehicles, where the performance of the wheel hub directly impacts vehicle handling, safety, and overall driving experience.

In addition to light vehicles, the water mist-cooled mold is also well-suited for manufacturing wheel hubs for commercial trucks and heavy-duty vehicles. These applications often involve larger and more complex wheel hub designs that must withstand higher loads and stresses. The advanced cooling technology provided by the mold ensures that these larger castings are uniformly cooled, reducing the risk of defects and improving the overall strength and reliability of the wheel hubs. This is particularly important for commercial vehicles, where the wheel hubs play a critical role in ensuring the safe and efficient operation of the vehicle under demanding conditions.

English

English 中文简体

中文简体