Precision plays a fundamental role in the production of wheel hub motorcycle casting molds. The wheel hub is a critical component of the motorcycle, responsible for supporting the wheel and ensuring s...

Wheel Hub Motorcycle Casting Mold Manufacturers

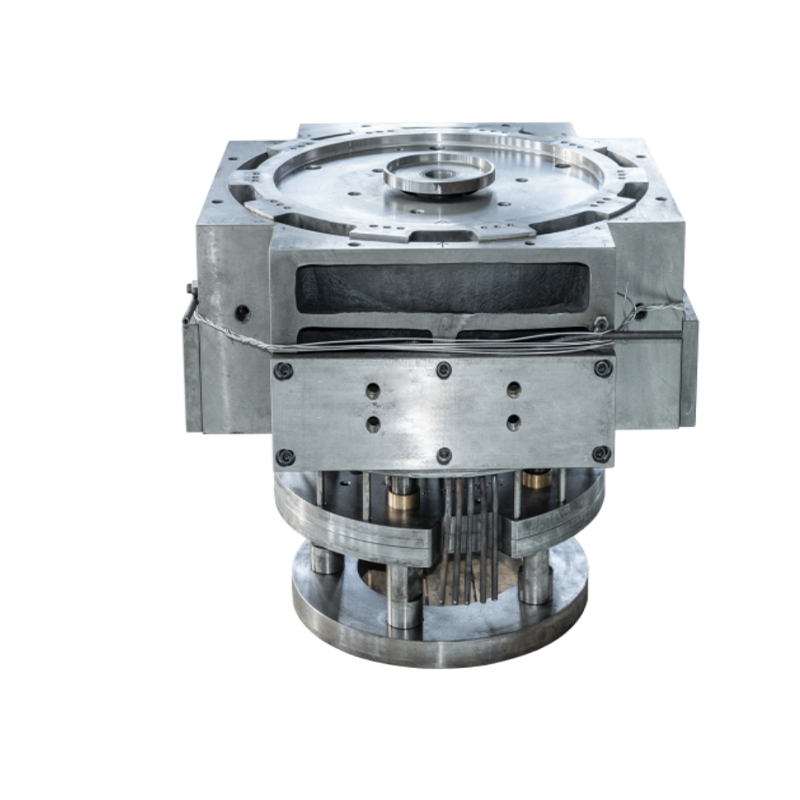

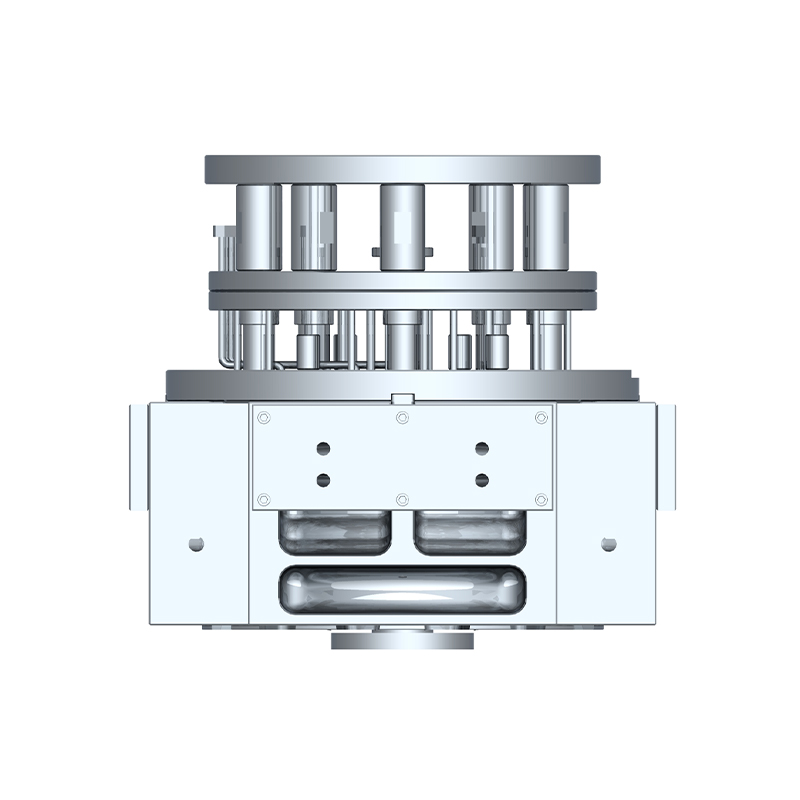

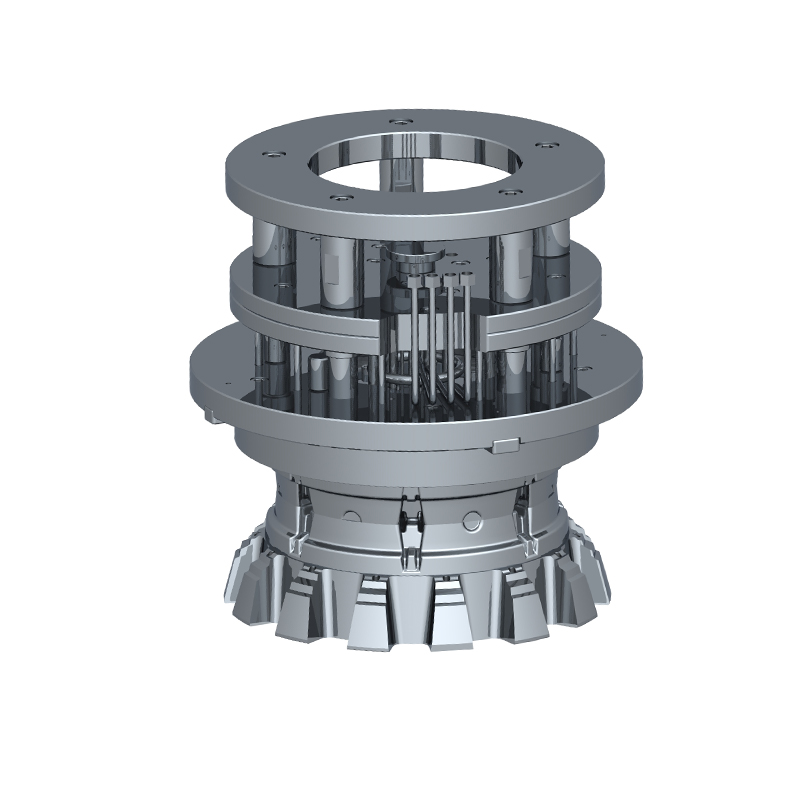

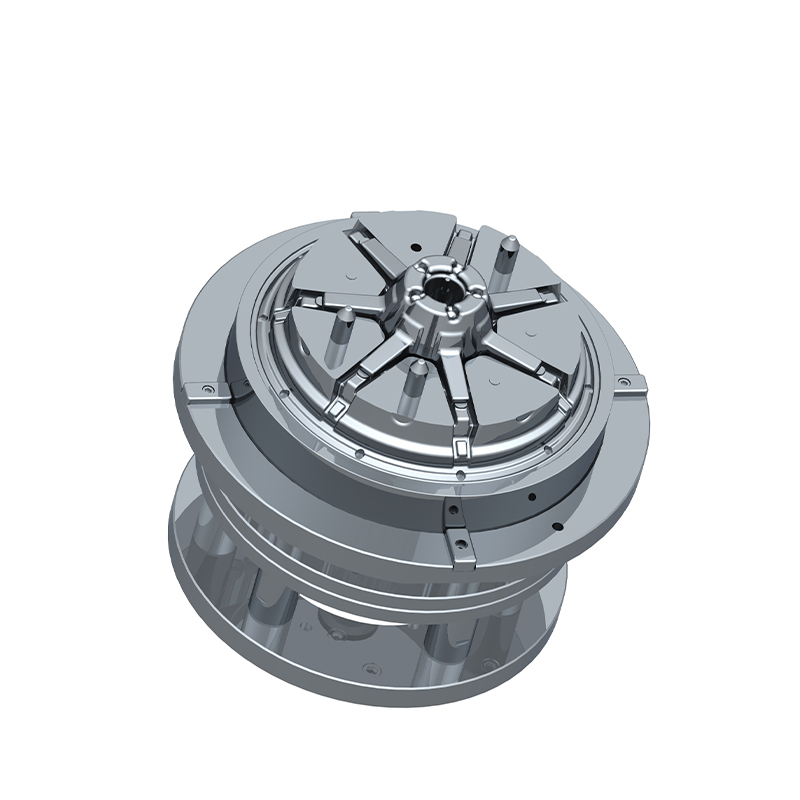

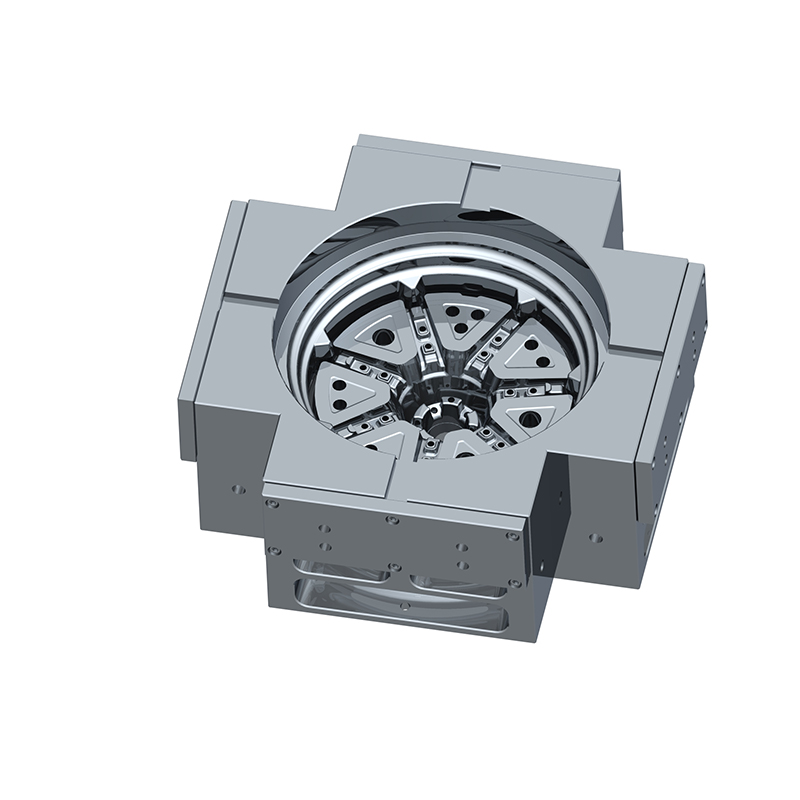

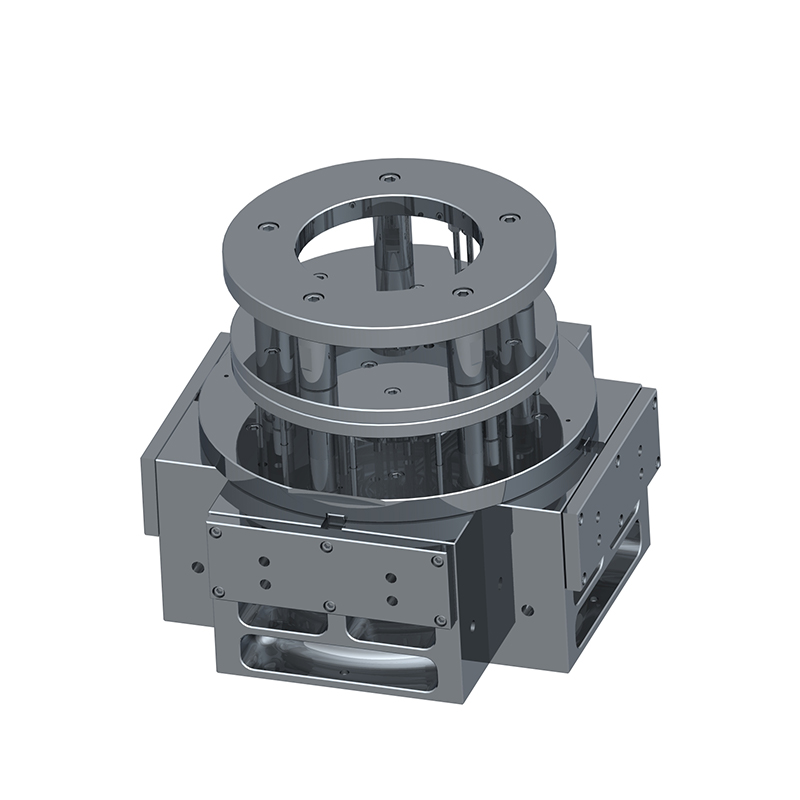

Wheel Hub Motorcycle Casting Mold is a high-precision mold used to manufacture motorcycle wheels. As an important part of a motorcycle, the wheel has a vital impact on the performance and safety of the vehicle. Motorcycle wheel hub casting molds are widely used in the motorcycle manufacturing industry to produce various types of motorcycle wheels, which play a key role in vehicle driving and directly affect the stability, handling, and safety of the motorcycle. Motorcycle wheel hub casting molds provide key support for the motorcycle manufacturing industry through their high-precision design, optimized cooling system, and lightweight characteristics. It not only ensures the high quality and precision of the wheel but also meets the motorcycle industry's strict requirements for high strength and durability. It is one of the key tools to improve motorcycle performance and safety.

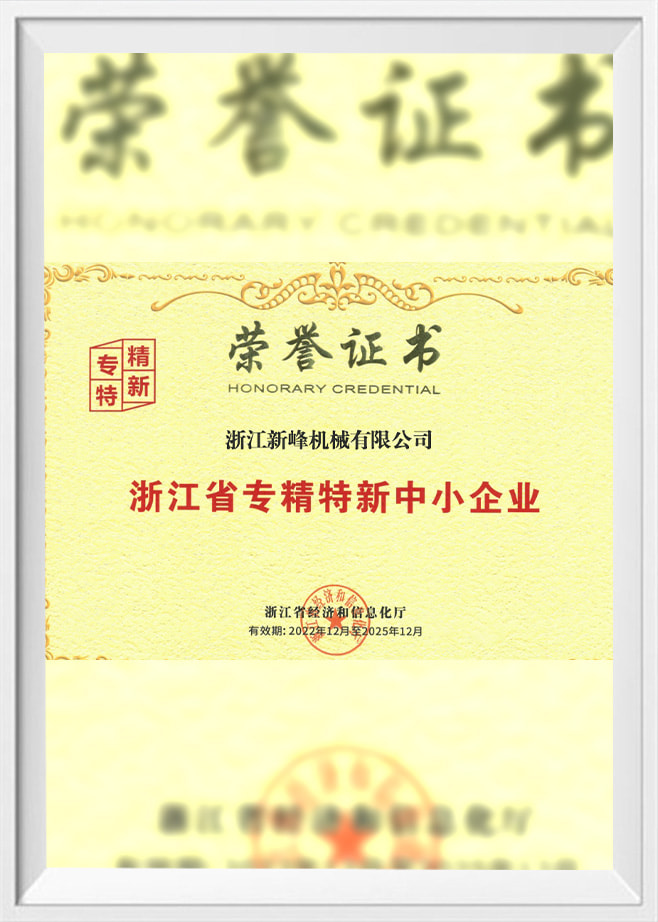

Zhejiang Xinfeng Machinery Co., Ltd. is professional China Wheel Hub Motorcycle Casting Mold Manufacturers and Custom Wheel Hub Motorcycle Casting Mold Factory.Zhejiang Xinfeng Machinery and Shengzhou Yuanfeng Mold are subsidiaries of Yongfeng Mold Group, with over 380 employees and annual sales of 550 million. Xinfeng specializes in aluminum wheel hub and structural casting molds, covering 30 acres, with a 16,000+ sqm plant, outputting 1,800 sets of molds annually, employing over 130 staff, including 30 skilled technicians and designers using CAD, UG, CATIA, etc. The company focuses on customer needs, innovation, and quality, implementing a mold production progress system and equipped with advanced machinery like CNC centers.

Yuanfeng Mold Co., Ltd. was established in Yongfeng Group, focusing on mold steel forging products, with multiple forging and electro slag remelting production lines, mainly producing mold raw materials such as H13 series and 35CrMo. The company actively promotes technological innovation and brand innovation, strengthens quality management, enhances corporate image, complies with ISO9001:2015 international quality system standards, and has won the titles of Shengzhou City's "30 Best" Enterprises, Integrity Enterprises, and National High-tech Enterprises.

Xinfeng Machinery actively participates in the "waste-free factory construction" and became a member of the "waste-free factory" in October 2022. It maintains long-term strategic cooperation with nearly 40 wheel hub factories and aluminum casting manufacturers, ranks among the top three in the aluminum alloy casting mold industry, leads the casting process industry, and produces 2,000 sets of molds annually. It is committed to using technology to improve product quality and using craftsmanship to create each product.

-

-

A wheel hub motorcycle casting mold is an essential tool in the manufacturing process of motorcycle wheel hubs. It plays a key role in shaping the molten metal into the precise dimensions required for...

-

A wheel hub differential pressure casting mold is a specialized mold used in the casting process to produce wheel hubs, commonly found in vehicles. The “differential pressure casting” technique involv...

1. Why has Wheel Hub Motorcycle Casting Mold become a key technology for electric vehicle innovation?

The reason why Wheel Hub Motorcycle Casting Mold has become a key technology for innovation in the field of electric vehicles is that it completely changes the power transmission method of traditional motorcycles. Traditional motorcycles transmit engine power to the rear wheels through chains or belts, while hub motors directly convert electrical energy into rotational force, reducing energy loss during transmission and significantly improving energy efficiency. In addition, the integrated design of the in-wheel motor simplifies the vehicle structure, reduces the weight of the vehicle body, and provides electric vehicles with longer cruising range and faster acceleration performance. More importantly, this technology responds to the urgent global need to reduce carbon emissions and promote green travel, opening up a new path for the sustainable development of the motorcycle industry. As consumers' acceptance of electric vehicles increases, Wheel Hub Motorcycle Casting Mold is gradually becoming a core technology that electric vehicle manufacturers are competing to develop, driving the transformation and upgrading of the entire industry.

2. How to ensure the accuracy and durability of Wheel Hub Motorcycle Casting Mold to meet high-performance requirements?

Ensuring the accuracy and durability of Wheel Hub Motorcycle Casting Mold is the key to ensuring stable performance of the wheel hub motor and extending the service life of electric vehicles. Mold design must fully consider the structural characteristics and working environment of the wheel hub motor, and use advanced computer-aided engineering (CAE) software for simulation analysis to optimize the mold structure, reduce stress concentration, and improve the overall strength of the mold. Secondly, the selection of mold materials is crucial. It is necessary to use high-strength, high-wear-resistant, and high-temperature-resistant alloy materials to ensure that the mold can maintain good stability and durability under harsh working conditions. Precision machining and heat treatment technology are also key links to ensure mold accuracy. By using high-precision CNC machine tools for processing, combined with scientific heat treatment technology, the internal stress of the material can be effectively eliminated and the dimensional accuracy and surface quality of the mold can be improved. Strict quality control and testing methods are also important guarantees to ensure the quality of molds.

3. How will Wheel Hub Motorcycle Casting Mold technology further promote the intelligent and personalized development of the motorcycle industry in the future?

In the future, Wheel Hub Motorcycle Casting Mold technology will be deeply integrated with intelligent technology to promote the development of the motorcycle industry in a more intelligent and personalized direction. On the one hand, as the core component of the electric vehicle power system, the in-wheel motor will achieve seamless connection with the on-board intelligent system. By integrating smart components such as sensors and controllers, in-wheel motors can monitor vehicle status in real time, adjust power output, and even realize autonomous driving functions. This intelligent integration will greatly improve the safety, comfort and convenience of motorcycles. On the other hand, as consumers' demand for personalization continues to grow, Wheel Hub Motorcycle Casting Mold technology will help motorcycle manufacturers provide more diverse appearance designs and more flexible configuration options. Through modular design, customized production and other methods, consumers can choose hub motors of different styles and performances and their supporting molds according to their own preferences and needs to create unique and personalized motorcycles. This trend of personalized customization will push the motorcycle industry to develop in a more diversified and differentiated direction.

English

English 中文简体

中文简体