We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

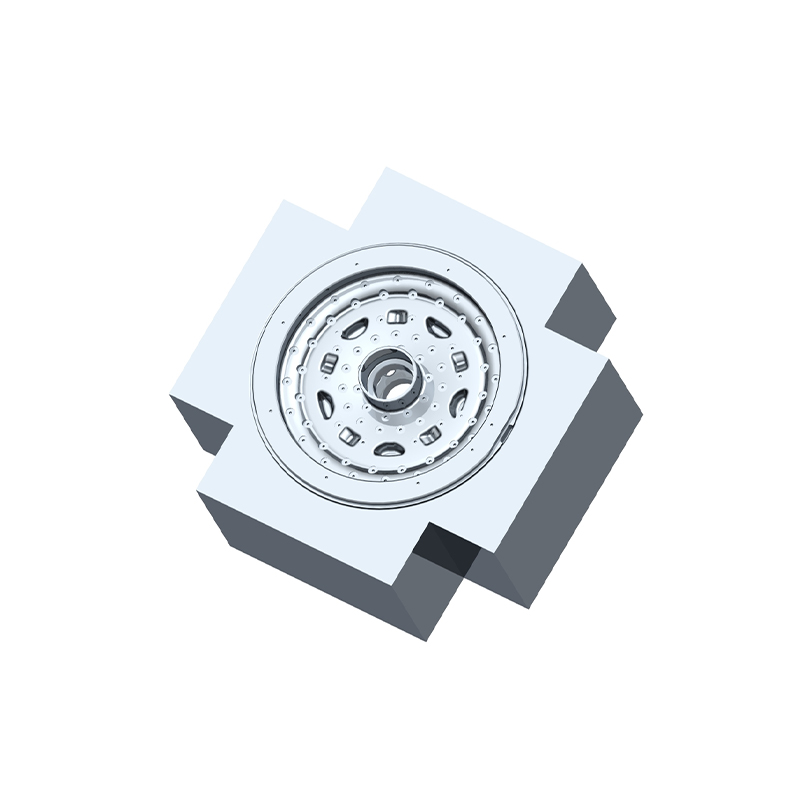

How Do Cooling Systems Impact the Life Cycle of Wheel Hub Differential Pressure Casting Molds?

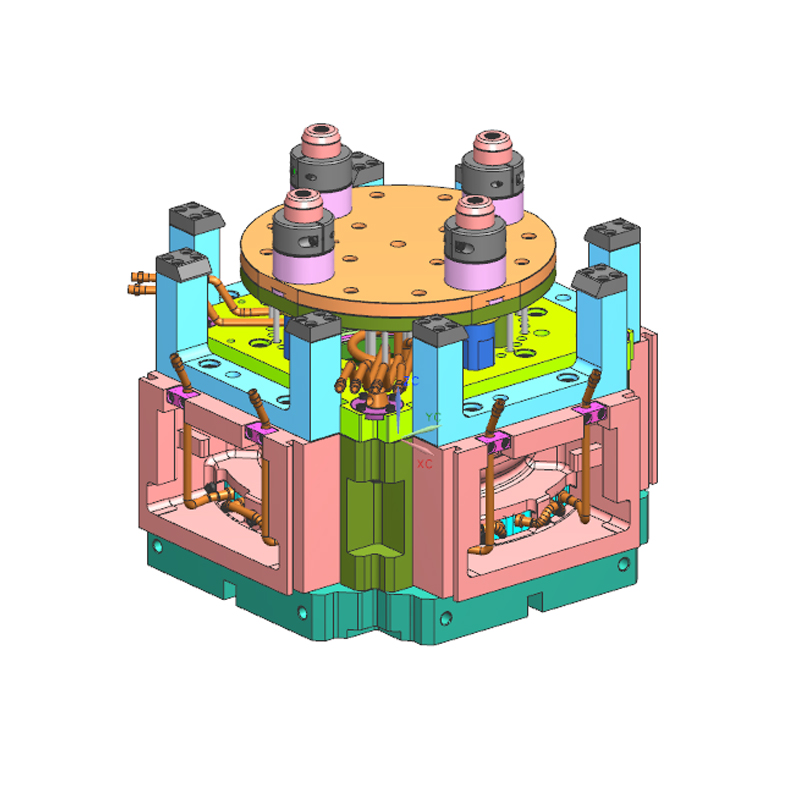

In wheel hub differential pressure casting, the cooling system of the mold not only affects the quality and production efficiency of the casting, but also directly determines the service life of the mold. Reasonable cooling design can delay the thermal fatigue of the mold, reduce the maintenance frequency, and improve economic benefits.

1. Thermal Stress and Mold Fatigue

During the casting process, the mold is subjected to repeated thermal shocks: when the high-temperature molten metal fills the cavity, the mold surface heats up rapidly, and then cools down rapidly after pouring is completed and the casting cools. The thermal cycle load caused by this alternating hot and cold will lead to:

The metal structure expands and contracts repeatedly, resulting in micro cracks;

The mold material has thermal fatigue cracks, which even penetrate the cavity;

The mold surface peels off, cracks and other early failure phenomena.

The cooling system can accurately adjust the local and overall temperature and achieve thermal stress relief by setting cooling water channels, oil cooling systems or gas circulation inside the mold. For example, arranging dedicated cooling channels in areas where heat loads are concentrated (such as wheel hub ribs and near the gate) can greatly reduce the risk of thermal fatigue in this area.

2. Cycle Time Optimization

The cooling efficiency of the mold is closely related to the entire casting cycle. A good cooling system brings the following benefits:

Fast solidification: Fast cooling speed helps aluminum alloy to solidify quickly and avoid coarse grains;

Reduced waiting time: Uniform cooling allows the mold to reach the safe mold opening temperature earlier and shortens the demolding time;

Reduced heat accumulation: Long-term use can prevent the overall temperature of the mold from rising and maintain a stable operating state.

Optimizing the cooling system can increase the number of castings (i.e., production capacity) per hour of the mold, while reducing the heat load of each mold, which means that the total number of thermal shocks the mold endures throughout its life cycle is reduced, thereby extending its service life.

3. Material Degradation and Oxidation

The high temperature working environment of the mold can easily cause oxidation, carburization or nitridation reactions on the material surface, especially in areas with poor heat dissipation such as ventilation grooves and corners. If the cooling is not timely or unevenly distributed, the following consequences will occur:

An oxide layer is formed on the mold surface, affecting the adhesion of the coating;

The hardness of the mold surface decreases, which is prone to wear;

The "ablation" phenomenon occurs, that is, the local metal is corroded or melted by the high-temperature metal liquid.

An efficient cooling system can control the mold surface temperature within a suitable range (such as between 200–350°C), ensuring metal filling while avoiding overheating, thereby slowing down material aging and extending the mold repair interval.

4. Hot Spot Management

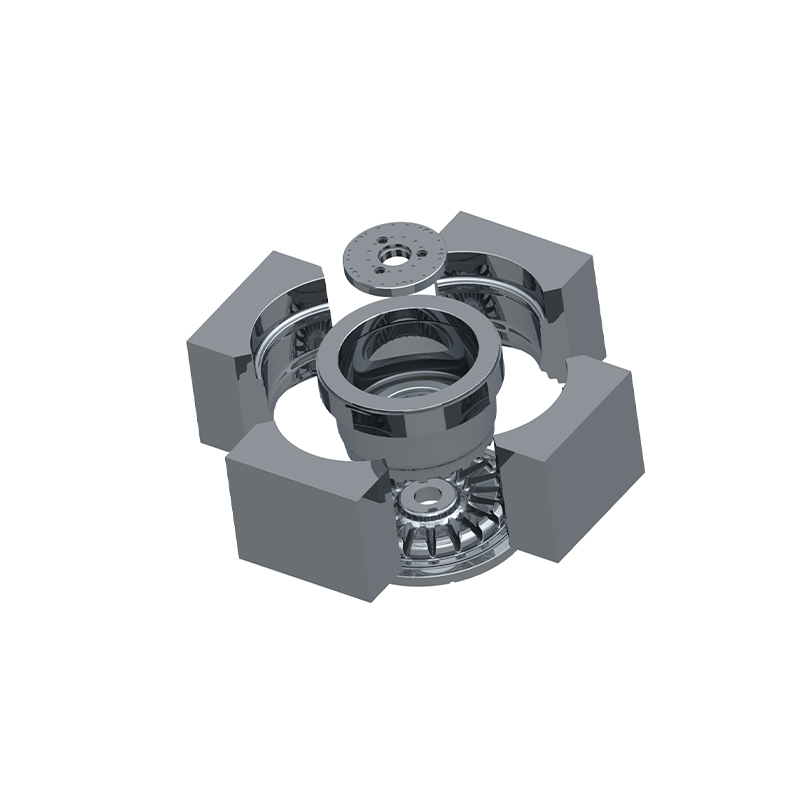

The "hot spots" in the mold are usually areas where heat is concentrated and difficult to dissipate, such as complex structural parts such as wheel hub reinforcement ribs and spoke roots. If these areas are not cooled enough, it will lead to:

Molding defects such as pores and shrinkage in the casting;

Repeated overheating of the mold locally leads to premature failure;

Thermal stress concentration forms deep cracks.

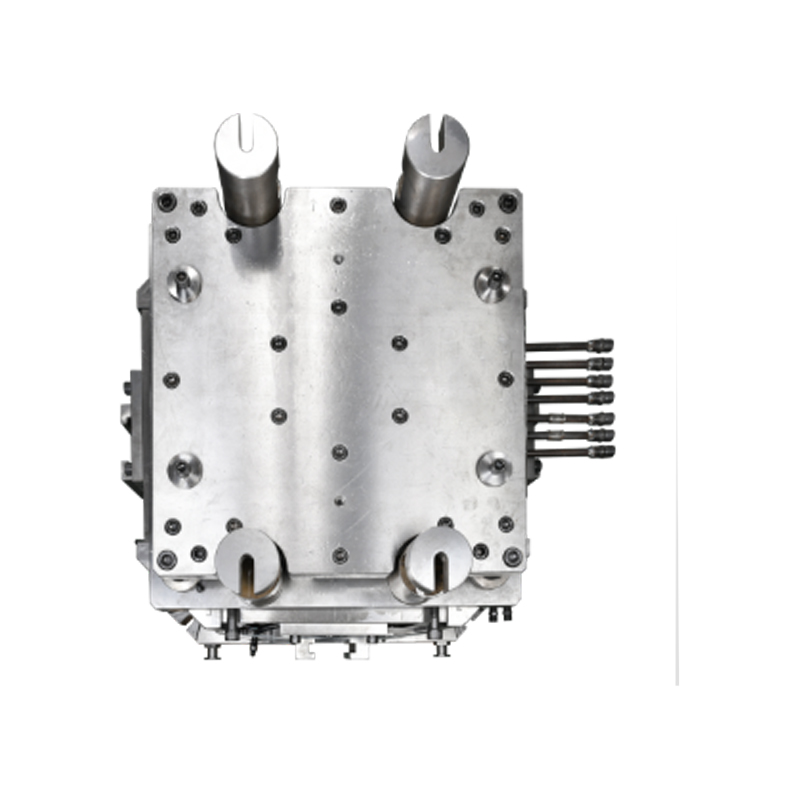

For these hot spots, modern cooling system designs use:

Conformal cooling channels (conformal cooling) fit the mold structure to ensure uniform cooling;

Zoned cooling control, using multiple independent circuits to accurately cool different areas;

Thermal simulation analysis (such as Magma, ProCAST, etc.) identifies high-risk areas in advance and optimizes cooling strategies.

This can extend the service life of the mold in the hot spot area and reduce the frequency of maintenance.

5. Lubrication and Coating Efficiency

The mold surface usually needs to be sprayed with lubricants and heat-insulating coatings to prevent aluminum liquid from sticking to the mold or mold corrosion, but these materials are sensitive to temperature:

If the mold temperature is too high, the lubricant will carbonize prematurely and lose its effect;

The coating is easily burned and peeled off, increasing mold wear;

When the mold temperature fluctuates greatly, the coating is difficult to adhere evenly, affecting the surface quality of the casting.

Effective cooling can keep the mold in a stable working temperature range, such as 220–280°C, so that the lubricant and coating can play the maximum effect, delay local mold wear, improve the durability of surface treatment, and reduce the frequency of mold renovation.

English

English 中文简体

中文简体