We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

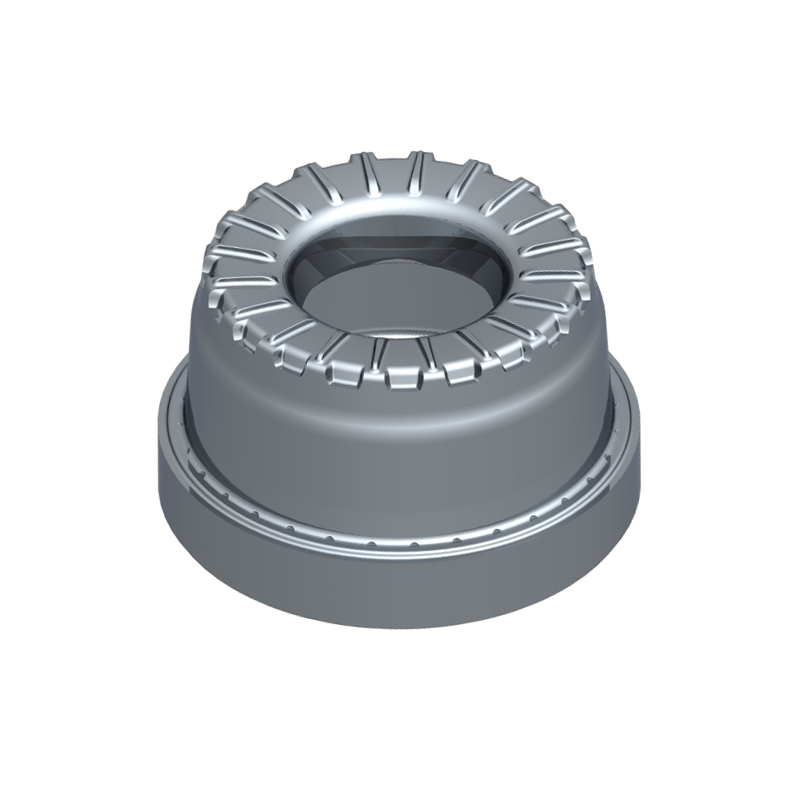

Wheel Hub Motorcycle Casting Mold: Key Features and Benefits Explained

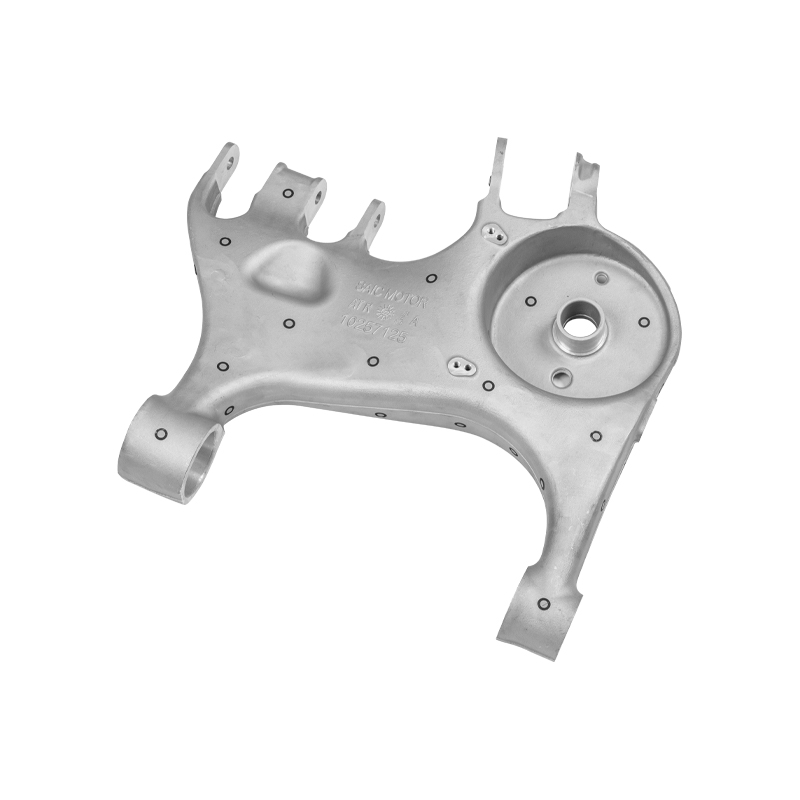

In the highly competitive motorcycle manufacturing industry, producing top-quality components is non-negotiable. One of the most critical parts that directly affect performance and safety is the wheel hub. Behind every precision-made wheel hub lies a high-performance wheel hub motorcycle casting mold—a specialized tool designed to create flawless, durable wheel hubs efficiently and consistently.

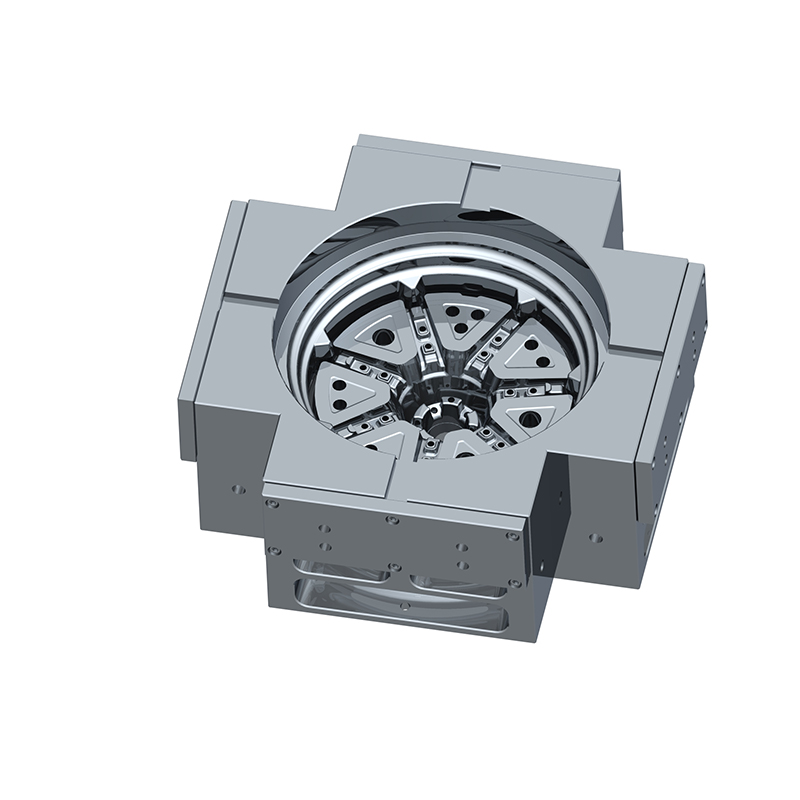

What Exactly Is a Wheel Hub Motorcycle Casting Mold?

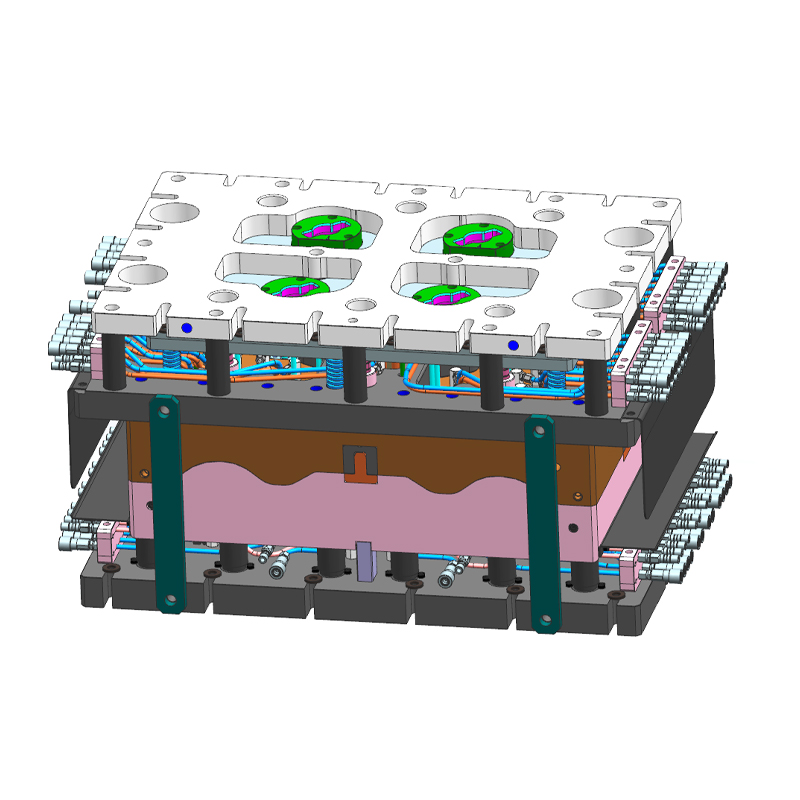

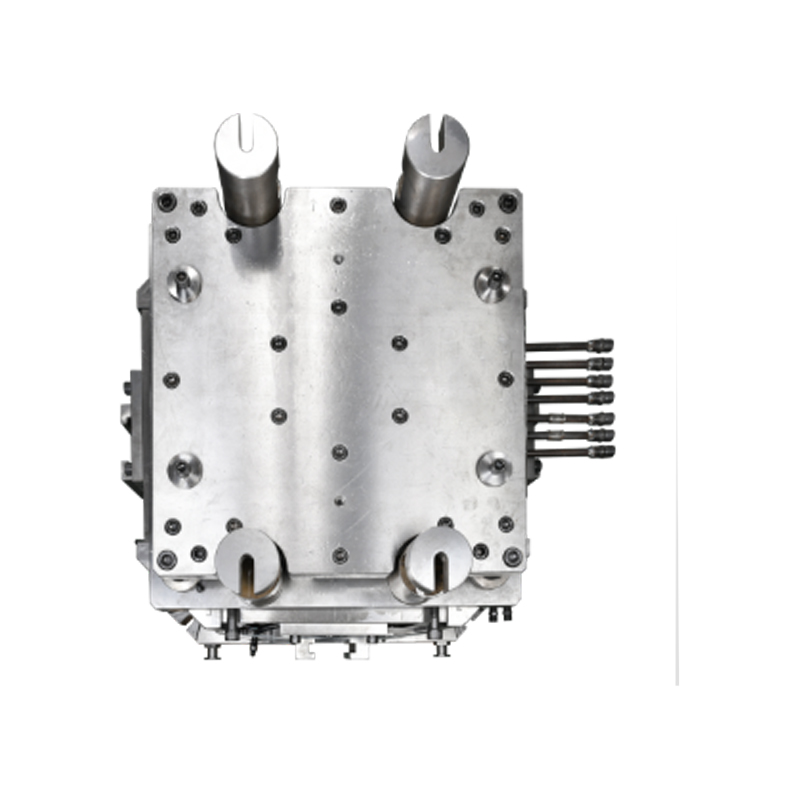

A wheel hub motorcycle casting mold is a precision-engineered mold used during the metal casting process. It shapes molten metal into the exact dimensions and specifications needed to produce reliable motorcycle wheel hubs. Typically made from high-strength steel alloys or other heat-resistant materials, these molds are built to endure the extreme conditions of molten metal casting.

Key Features That Set Quality Wheel Hub Casting Molds Apart

1. Exceptional Precision and Accuracy

In motorcycle manufacturing, every millimeter counts. High-quality molds are designed using advanced CAD/CAM software to achieve tight dimensional tolerances. This precision ensures the wheel hub fits perfectly with other components such as bearings, brakes, and spokes, minimizing the need for costly rework.

2. Robust and Heat-Resistant Materials

Casting molds must withstand extreme temperatures and repeated thermal cycling. Premium molds use durable steel alloys and special surface treatments to resist wear, corrosion, and thermal fatigue—extending the mold’s service life and reducing downtime.

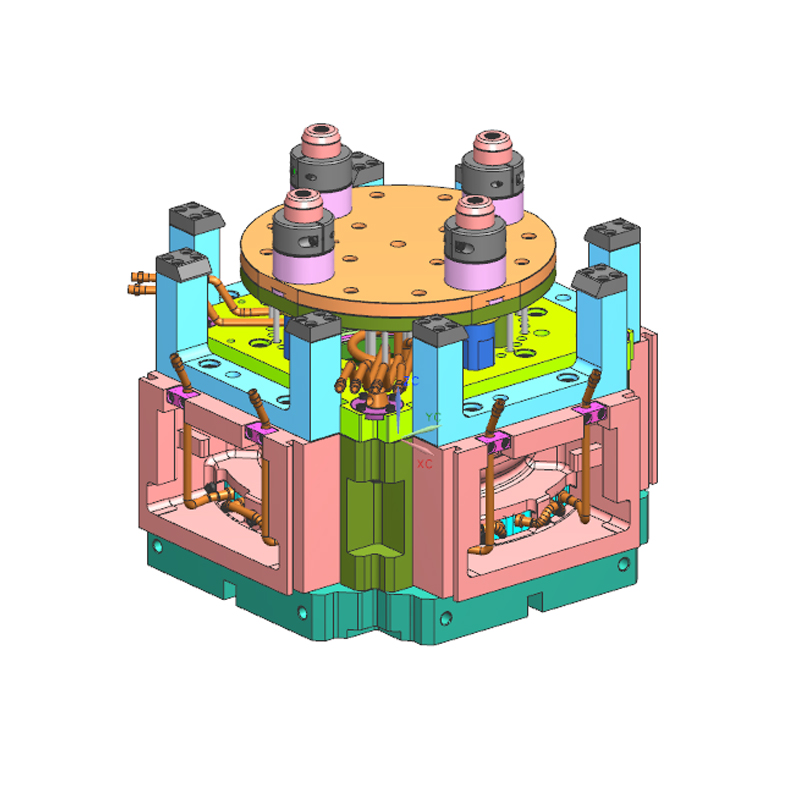

3. Advanced Cooling System Integration

Efficient cooling channels incorporated into the mold design help dissipate heat quickly, preventing defects like warping, porosity, and shrinkage in the finished wheel hubs. Faster cooling times also translate into increased production speed and higher output.

4. Modular and Maintainable Construction

Some molds feature modular components, allowing manufacturers to replace only worn sections rather than the entire mold. This modularity cuts maintenance costs and keeps production running smoothly.

5. Versatility Across Casting Techniques

Whether you specialize in sand casting, die casting, or investment casting, molds can be tailored to suit your preferred process, production volume, and material choices—ensuring you achieve the best balance of quality and cost-efficiency.

Why Invest in High-Quality Wheel Hub Motorcycle Casting Molds?

1. Superior Product Quality

Reliable molds consistently produce wheel hubs with excellent surface finishes and dimensional accuracy. This reduces the need for secondary machining, saving time and money while delivering a premium end product.

2. Boosted Production Efficiency

Durable molds with optimized thermal management allow faster cycle times and minimize mold-related production delays, helping manufacturers meet tight deadlines and large order volumes.

3. Long-Term Cost Savings

While high-quality molds may come with a higher upfront cost, their durability, ease of maintenance, and reduced scrap rates lead to significant savings over the product lifecycle.

4. Customization and Design Flexibility

Manufacturers can tailor mold designs to produce wheel hubs for different motorcycle models or customize features based on client requirements—enabling more diverse product lines and meeting market demands.

5. Enhanced Safety and Performance

Accurate casting molds ensure that wheel hubs maintain structural integrity and fit precisely, directly contributing to motorcycle safety, reliability, and rider confidence.

How to Choose the Right Wheel Hub Motorcycle Casting Mold Supplier?

Selecting a trusted supplier with proven expertise in casting mold design and manufacturing is crucial. Look for a partner who offers:

Technical support and consultation on mold design and material selection

Customization capabilities to meet your specific production needs

Strict quality control during mold manufacturing

After-sales support and maintenance services

English

English 中文简体

中文简体