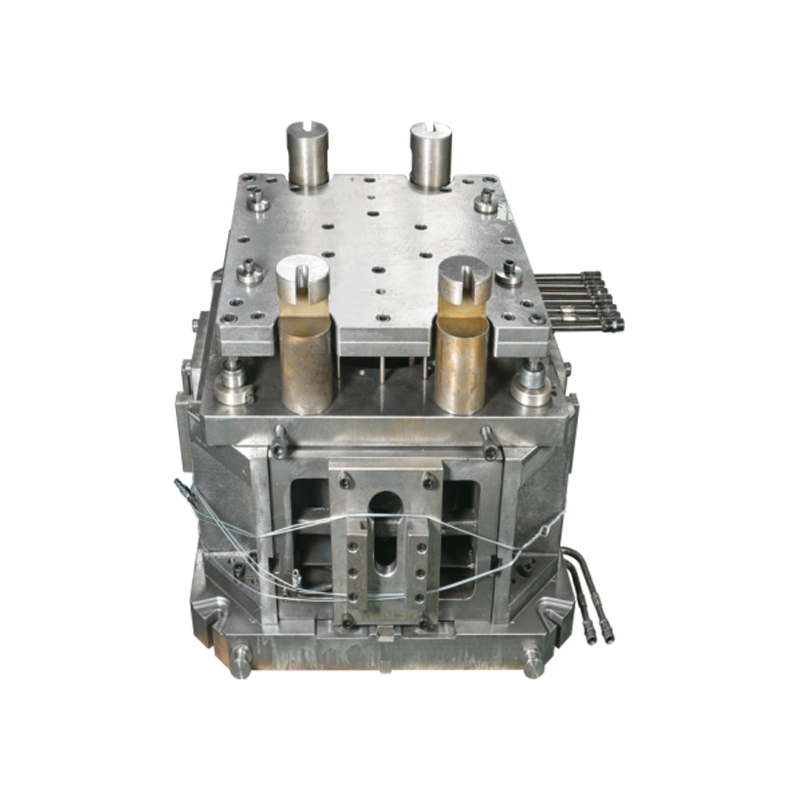

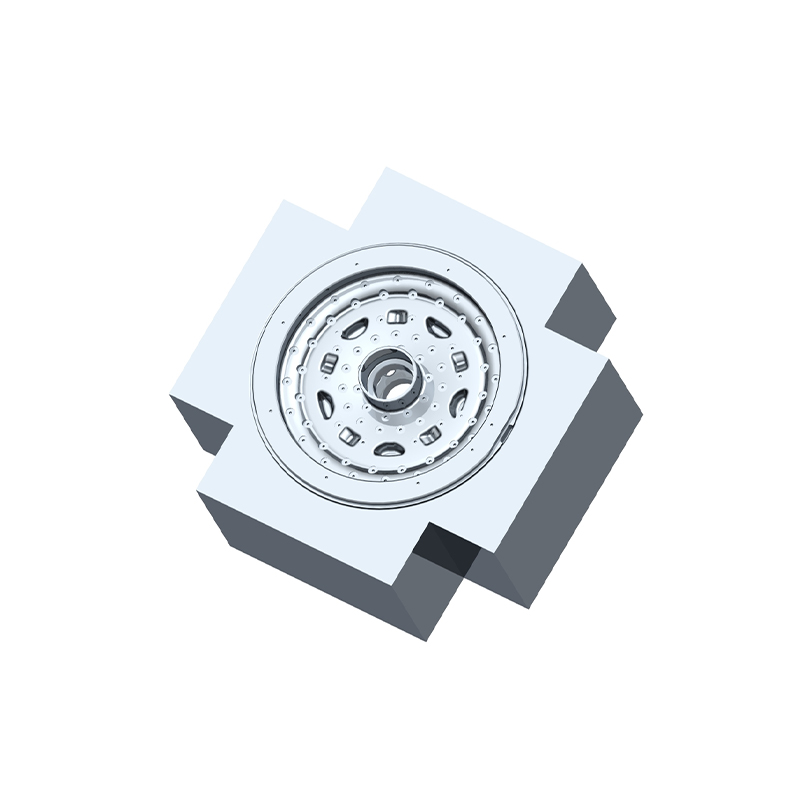

We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

Why Are Casting Tooling Fixture Molds Preferred Over Injection Molds for Certain Applications?

In manufacturing and metalworking, choosing the right tooling for a project is crucial to its success. Casting tooling fixture molds and injection molds are two commonly used production processes. While both processes are used to shape materials, there are several reasons why casting tooling fixture molds are preferred over injection molds for certain applications.

1. Complex Geometries and Intricate Designs

Casting tooling fixture molds offer significant advantages in producing complex geometries and intricate designs.

Casting Tooling Molds: Ideal for Complex Designs

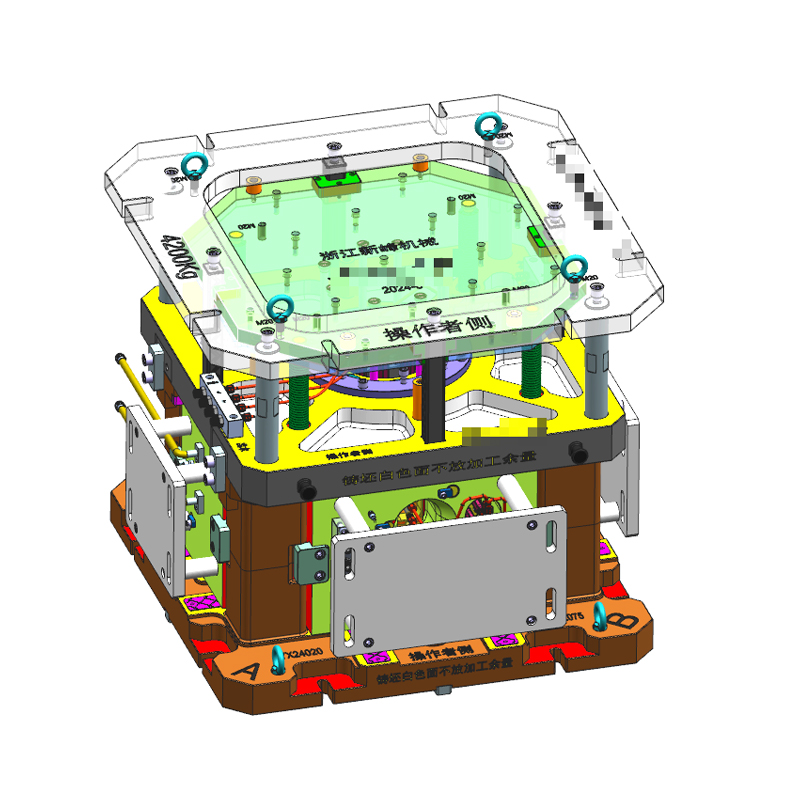

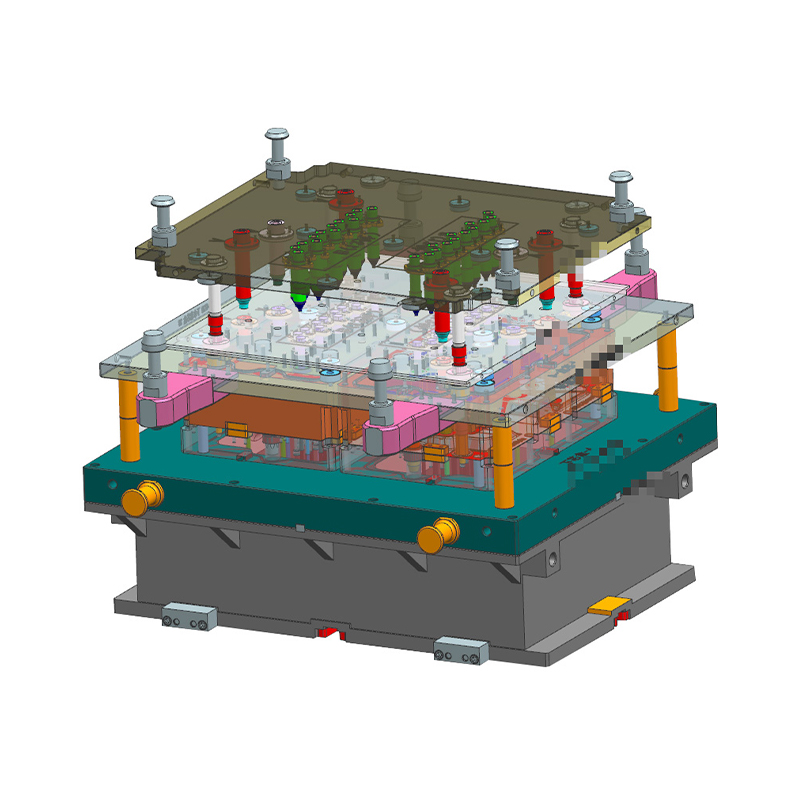

Casting tooling fixture molds are particularly excellent for producing components with complex geometries. Whether it is parts with internal cavities, designs with undercuts, or components requiring embedded holes, casting molds can easily handle these challenges. The casting process involves pouring molten material into a mold, which allows the material to fill every detail and crevice of the mold, ensuring precise designs. Even highly complex shapes, such as deep cavities, thin walls, or parts with curves, can be produced with higher accuracy using casting.

Injection Molds: Limited by Design Complexity

In contrast, injection molds face more challenges when producing complex components. Injection molding forces thermoplastic material into the mold under high pressure, which can create difficulties in forming intricate designs, especially when parts have deep cavities, undercuts, or internal features. Injection molds often require additional auxiliary tools, such as cooling channels and complex ejection mechanisms, to ensure the quality of the molded part.

Table: Suitability of Different Molds for Complex Designs

| Feature | Casting Tooling Molds | Injection Molds |

|---|---|---|

| Suitable for Complex Designs | Yes | No |

| Internal Cavity/Deep Designs | Easy to Achieve | Difficult to Achieve |

| Thin Wall Structures | Achievable | Limited |

| Complex Geometries | Flexible | Requires Special Design |

2. Material Flexibility

When it comes to material selection, casting tooling fixture molds generally offer greater material flexibility compared to injection molds.

Casting Tooling Molds: Wide Material Range

Casting can handle a wide range of materials, particularly in metalworking. For example, casting molds can be used for various metals, including cast iron, steel, aluminum, and brass. These materials often have high melting points or specialized physical and chemical properties, making them difficult to process with injection molding. Additionally, casting molds allow for adjustments in material formulations to optimize the properties of the final product.

Injection Molds: Limited Material Options

In contrast, injection molds are mainly used for thermoplastic and some thermosetting plastics. While material science has advanced to allow the use of special materials in injection molding, the range of materials that can be processed is still relatively limited. Especially when dealing with metals or applications requiring high strength, injection molds may not be suitable.

3. Cost-Effective for Low-Volume Production

For low-volume production, casting tooling fixture molds are typically more cost-effective than injection molds.

Casting Tooling Molds: Lower Initial Cost for Small Batches

One of the significant advantages of casting tooling fixture molds is their lower initial investment cost. Casting molds are generally cheaper to produce than injection molds, making them ideal for low-volume or small-batch production. In low-volume situations, the cost per part is spread over fewer units, resulting in a higher return on investment. Additionally, the maintenance and adjustment costs for casting molds are usually lower than those for injection molds.

Injection Molds: High Setup Cost for Small Quantities

Injection molds typically involve higher initial costs, particularly when producing small quantities. While injection molding can lower unit costs in high-volume production, the setup costs for small runs can make injection molds less economical for low-volume production. Additionally, maintaining and modifying injection molds can be expensive.

4. Less Material Waste

In terms of material utilization, casting tooling fixture molds are generally more efficient than injection molds, especially for certain types of metalworking and casting applications.

Casting Tooling Molds: More Efficient Material Use

The casting process involves pouring molten metal into a mold, which tends to result in less waste material. Excess material can often be recycled and reused in the next casting cycle, improving material efficiency. Because casting molds are more flexible in design, they can also be optimized to minimize waste, especially when producing complex parts.

Injection Molds: Potential for Material Waste

While injection molding is efficient in using material per part, there can be significant material waste generated during the process, especially when dealing with complex parts or high-viscosity materials. Additionally, material waste can occur during the setup process or when parts are rejected due to defects.

5. Improved Durability and Strength

For applications that require high strength and durability, casting tooling fixture molds offer superior material properties.

Casting Tooling Molds: Superior Strength for Metal Parts

The casting process produces parts with greater strength and durability, especially when dealing with metals. The cooling and solidification of metal in the mold results in a uniform structure and better mechanical properties. As a result, cast parts tend to have higher tensile strength and corrosion resistance, performing better in high-load and harsh environments.

Injection Molds: Material Properties May Be Limited

In contrast, injection molds are typically used to produce plastic parts, which may not offer the same strength or durability as metal parts. While modern injection molding technologies can improve the mechanical properties of plastics, for applications requiring high strength or extreme operating conditions, plastic parts may not be sufficient. Therefore, for high-strength applications, casting molds are usually the better choice.

6. Customization and Adaptability

Casting tooling fixture molds often provide greater customization and adaptability compared to injection molds.

Casting Tooling Molds: Flexibility for Custom Designs

Casting is particularly well-suited for producing custom-designed parts. Whether in the aerospace, automotive, or military sectors, custom components are often needed that meet specific performance or design requirements. Casting molds offer more flexibility and can easily be modified to accommodate unique needs. The production cycle for casting molds is also shorter, and they can be adjusted more easily to suit custom specifications.

Injection Molds: High Customization Cost

While injection molds can be customized, the cost of customization can be high. Especially when dealing with complex designs or requiring extremely precise details, modifying injection molds can lead to higher costs. Once an injection mold is created, there is limited room for modification, making it more challenging and expensive to adapt to changing requirements.

7. Fewer Limitations on Part Size

When it comes to part size, casting tooling fixture molds generally have fewer size constraints than injection molds.

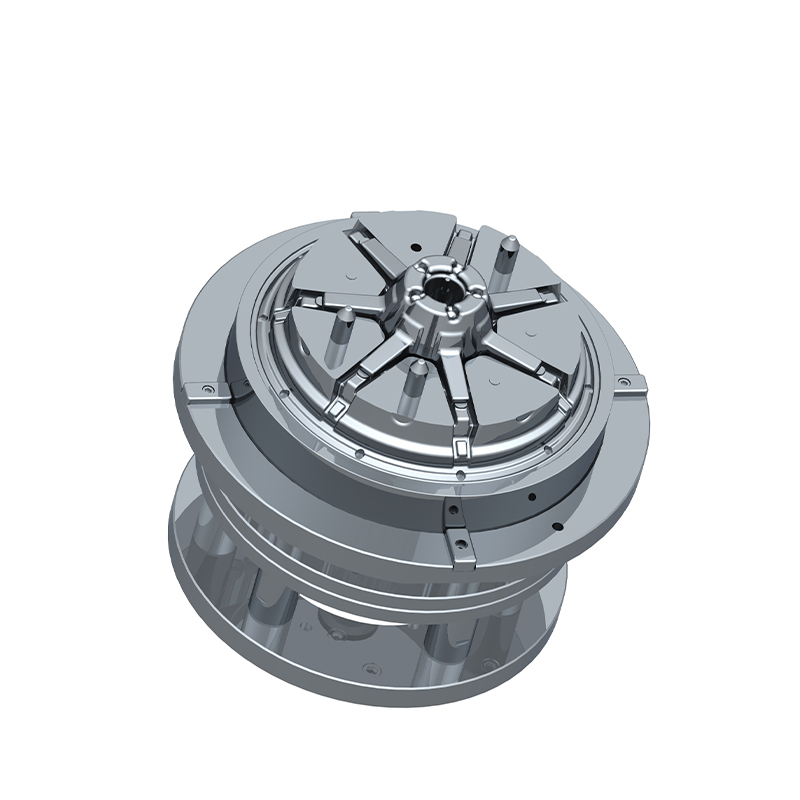

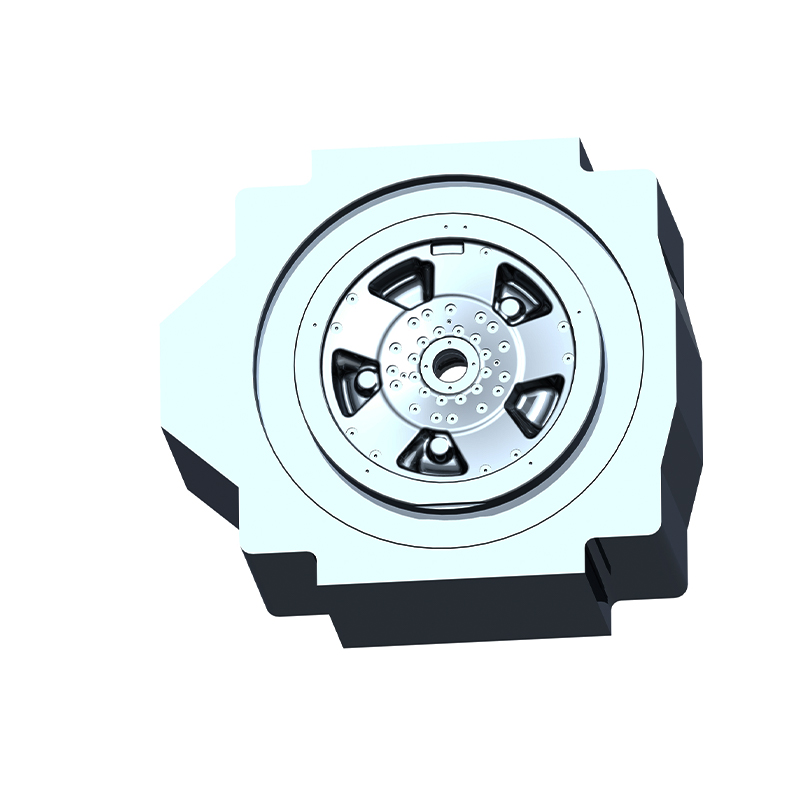

Casting Tooling Molds: Can Handle Larger Parts

Casting molds can handle larger parts, making them ideal for producing components for heavy machinery or industrial applications. The mold size can be adjusted to accommodate larger and heavier components. Unlike injection molds, which are limited by size, casting molds can be scaled to fit a variety of part sizes.

Injection Molds: Size Constraints

Injection molds have significant size limitations, especially when producing large parts. The cost of creating larger injection molds is high, and maintaining the quality of large parts can be challenging. As a result, injection molds are better suited for medium or small parts, while large parts may require more costly and complex tooling.

English

English 中文简体

中文简体