We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

What Is a Wheel Hub Differential Pressure Casting Mold and How Does It Work?

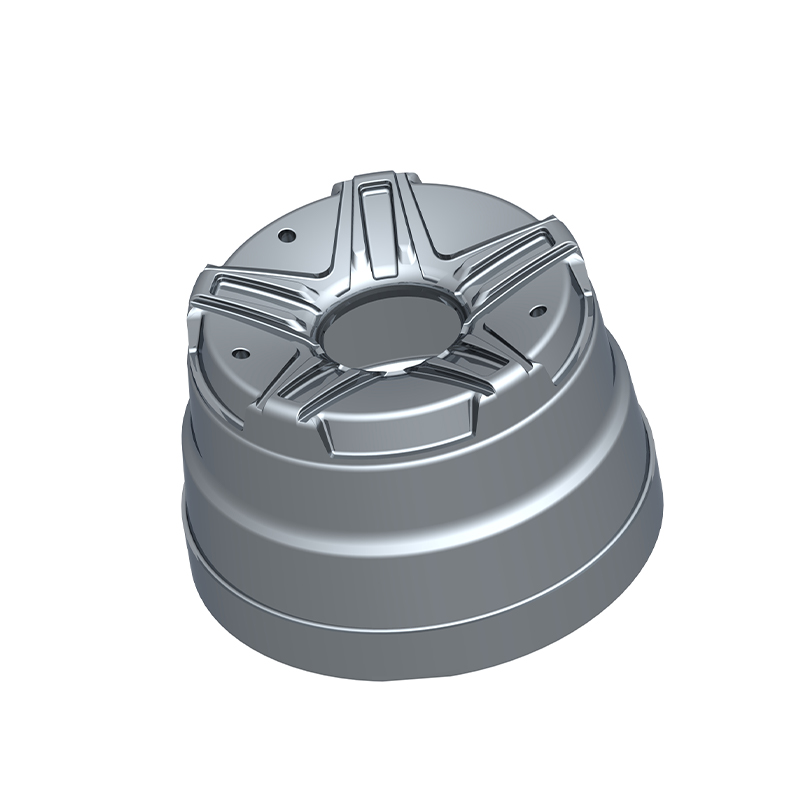

In the ever-evolving world of automotive manufacturing, precision engineering and cost-efficiency are vital. One of the most critical components in any vehicle’s suspension and wheel assembly is the wheel hub. The wheel hub serves as the connection point between the wheel and the vehicle, enabling smooth rotation and load transfer. As such, its design and manufacturing must meet strict performance and safety standards. To achieve this, modern manufacturing techniques like differential pressure casting have revolutionized the way wheel hubs are made.

What Is Differential Pressure Casting?

Before diving into the specifics of wheel hub differential pressure casting molds, it’s essential to understand what differential pressure casting (DPC) is.

Differential Pressure Casting Explained

Differential pressure casting is a specialized technique used to cast metals with high precision and excellent mechanical properties. In this process, molten metal is forced into a mold using pressure. The key differentiator of this method is that it involves a pressure differential—essentially a pressure difference between the mold cavity and the surrounding environment.

In traditional gravity casting methods, molten metal is poured into a mold, relying on gravity to fill the mold cavity. In contrast, differential pressure casting uses controlled air pressure (either positive or negative) to enhance the flow of molten metal, ensuring complete mold filling and reducing the likelihood of defects like air pockets, voids, and shrinkage.

How Differential Pressure Casting Works

The differential pressure casting process works as follows:

- Mold Preparation: The mold is placed inside a pressure chamber, where it is sealed to prevent air leaks.

- Molten Metal Injection: Molten metal is injected into the mold under pressure, which ensures that even the most intricate parts of the mold are filled evenly and without gaps.

- Solidification Under Pressure: As the metal cools and solidifies, the pressure inside the mold helps maintain uniform metal flow, preventing defects during the cooling process.

- Mold Removal: After the metal has solidified, the mold is opened, and the cast part is removed. The differential pressure ensures that the part is solid and of high quality.

The key benefits of differential pressure casting are its ability to create parts with high dimensional accuracy, fewer defects, and improved mechanical properties. These advantages make it particularly well-suited for manufacturing complex components like wheel hubs.

What Is a Wheel Hub Differential Pressure Casting Mold?

A wheel hub differential pressure casting mold is a specifically designed mold used for the differential pressure casting process to create wheel hubs. Wheel hubs are integral components in vehicles, providing the interface between the wheel and the axle. Since wheel hubs must withstand significant mechanical stresses, such as those caused by braking, turning, and acceleration, it is crucial that they are made from high-strength materials with precise geometries.

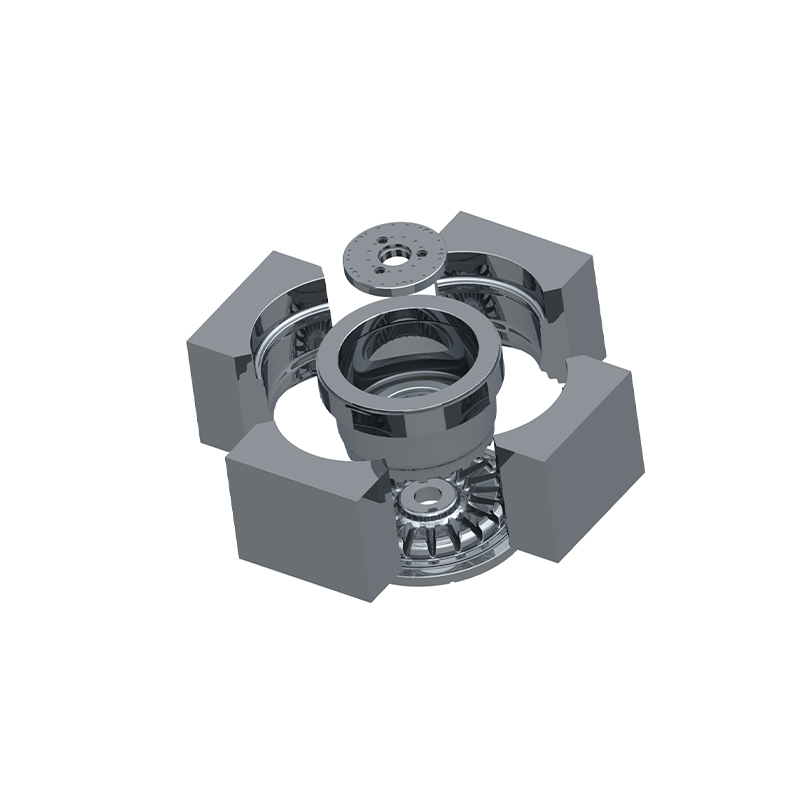

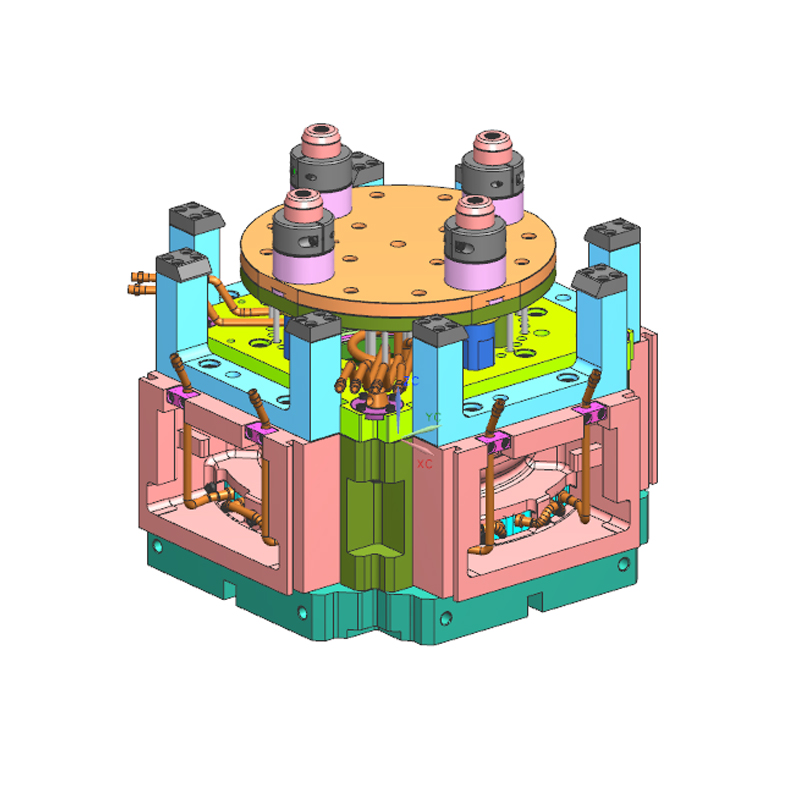

Design and Features of a Wheel Hub Mold

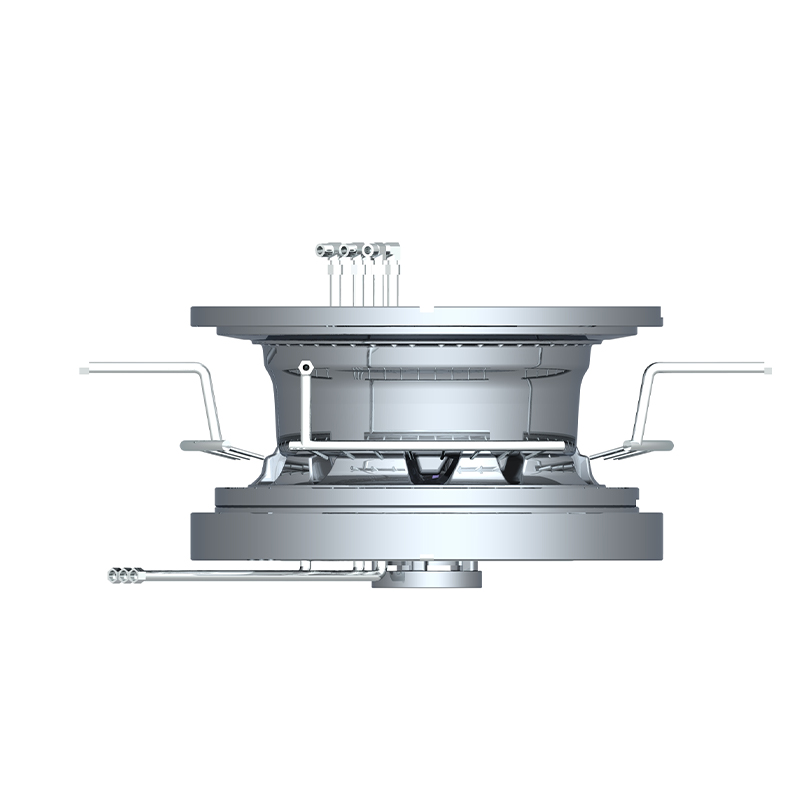

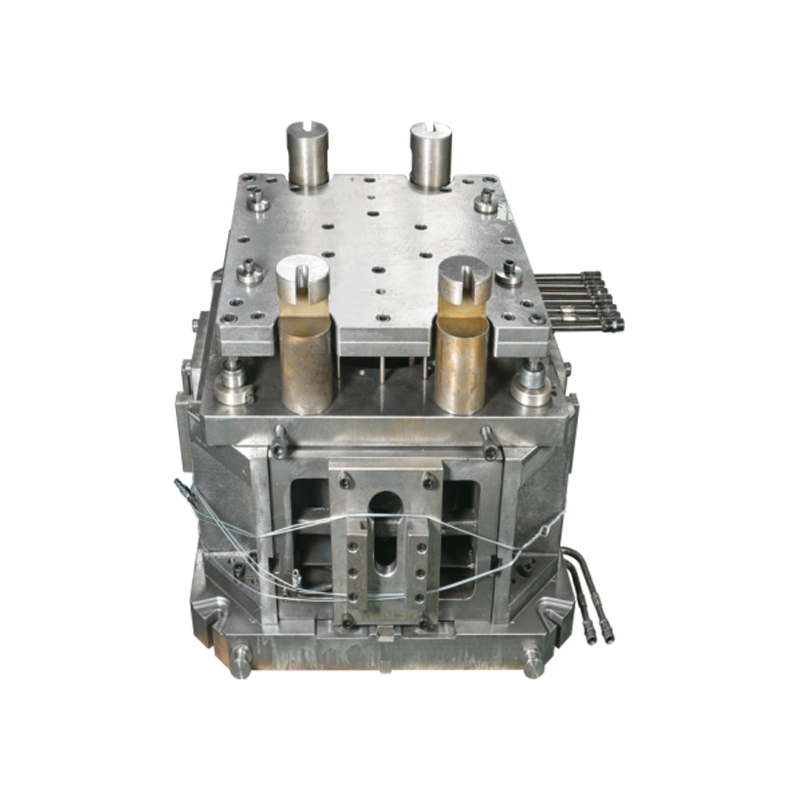

The mold used in differential pressure casting for wheel hubs is engineered with meticulous attention to detail. It is made of high-strength materials that can withstand both the high temperatures of molten metal and the pressures involved in the casting process. The design of the mold will typically reflect the final shape and size of the wheel hub, including bolt holes, intricate surfaces, and the central bearing interface.

Some important design features of a wheel hub differential pressure casting mold include:

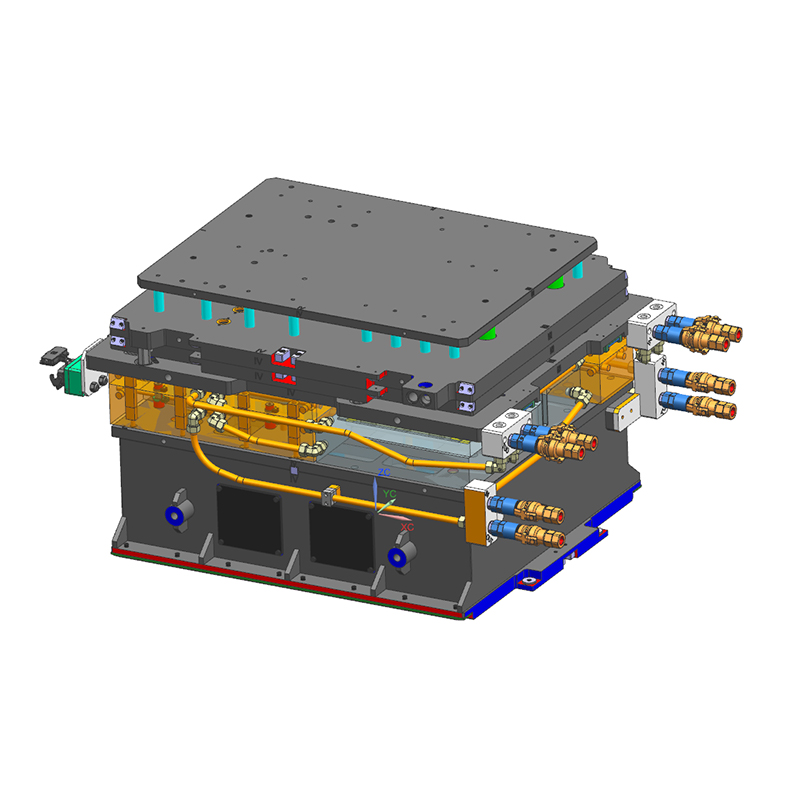

- Pressure Chamber: The mold is housed in a pressure chamber that can generate the necessary pressure differential to force the molten metal into the mold.

- Venting System: A carefully designed venting system ensures that gases and air are expelled from the mold cavity during the filling process, preventing defects.

- Cooling Channels: The mold will have embedded cooling channels that regulate the cooling process of the metal, which is vital to avoid defects like cracking or warping.

- Ejection Mechanism: Once the wheel hub has cooled and solidified, an ejection mechanism is used to remove the part from the mold without damaging it.

The mold is also designed with high precision, as wheel hubs often have tight tolerances that must be maintained for the parts to function correctly in the vehicle’s suspension system.

How Does a Wheel Hub Differential Pressure Casting Mold Work?

The operation of a wheel hub differential pressure casting mold follows a series of carefully controlled steps. These steps are essential to ensuring that the final wheel hub has the necessary strength, durability, and dimensional accuracy required for its application in vehicles. Let’s take a deeper dive into how the process unfolds.

1. Mold Preparation

Before the casting process begins, the mold must be properly prepared. This involves cleaning and inspecting the mold to ensure there are no defects that could interfere with the casting process. Additionally, the mold is coated with a release agent, which helps with the removal of the cast part after it has cooled. This coating also prevents any molten metal from sticking to the mold’s surfaces, reducing the chances of defects.

The mold is then placed inside the pressure chamber, where it is sealed tightly. This step is crucial for creating the pressure differential that will drive the molten metal into the mold cavity.

2. Injection of Molten Metal

Once the mold is secured in the pressure chamber, molten metal (usually an alloy like aluminum, magnesium, or other high-strength metals) is injected into the mold cavity. In the differential pressure casting process, the molten metal is pushed into the mold using controlled air pressure. This differential pressure is carefully managed to ensure that the molten metal flows evenly and fills all parts of the mold, including thin walls and complex geometries like bolt holes or grooves.

The pressure forces the metal to fill the mold completely and uniformly. This is a critical step, as incomplete mold filling can lead to defects like voids or weak spots in the final product. The controlled pressure ensures that these issues are minimized.

3. Solidification Under Pressure

Once the molten metal is injected into the mold, it begins to cool and solidify. The differential pressure maintained during solidification helps ensure that the metal cools evenly, preventing the formation of defects like cracks or warping. The pressure also keeps the metal tightly packed into the mold cavity, ensuring a dense, solid final product.

The cooling process is managed through the cooling channels embedded in the mold. These channels circulate coolant to control the rate at which the molten metal solidifies. Proper cooling is essential to avoid internal stresses or uneven solidification, which could compromise the strength and integrity of the wheel hub.

4. Mold Opening and Part Removal

Once the wheel hub has solidified, the mold is carefully opened, and the casting is removed. Depending on the mold design, an ejection system may be used to push the solidified wheel hub out of the mold without causing damage. The differential pressure applied during casting ensures that the wheel hub comes out with high dimensional accuracy, requiring minimal post-casting finishing.

At this stage, the wheel hub may undergo additional steps like cleaning, deburring, or surface treatment to ensure it meets the required specifications.

5. Final Inspection and Testing

After the casting has been removed from the mold, the wheel hub undergoes thorough inspection and testing. This may include visual inspection for surface defects, dimensional checks using coordinate measuring machines (CMM), and strength testing. For critical components like wheel hubs, non-destructive testing (NDT) methods, such as ultrasonic testing or x-ray inspection, may also be used to check for internal defects.

Benefits of Using Wheel Hub Differential Pressure Casting Molds

The use of differential pressure casting molds offers numerous advantages when manufacturing wheel hubs. Below are some of the key benefits:

| Benefit | Explanation |

|---|---|

| High Precision and Dimensional Accuracy | The pressure-driven metal flow ensures that even complex geometries are cast with high precision, reducing the need for post-processing. |

| Reduced Defects | The even filling of the mold reduces defects like air pockets, voids, and shrinkage, leading to a stronger, more reliable wheel hub. |

| Better Mechanical Properties | The controlled solidification process results in wheel hubs with superior tensile strength, fatigue resistance, and overall durability. |

| Increased Production Speed | The pressure-driven flow accelerates the filling process, reducing cycle times compared to traditional casting methods. |

| Cost-Effective | By minimizing material waste and defects, differential pressure casting offers a more efficient and cost-effective manufacturing process. |

Applications of Wheel Hub Differential Pressure Casting Molds

Wheel hubs manufactured using differential pressure casting molds are used in a wide range of applications, including:

- Passenger Vehicles: Lightweight and durable wheel hubs for everyday use in cars, SUVs, and crossovers.

- Commercial Vehicles: Heavy-duty wheel hubs for trucks, buses, and other commercial vehicles that require enhanced strength and performance.

- Racing and Performance Vehicles: Lightweight, high-strength wheel hubs for sports cars, racing vehicles, and high-performance applications.

- Electric Vehicles (EVs): Specialized wheel hubs for EVs, which require lighter components without sacrificing strength or durability.

English

English 中文简体

中文简体