We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

A Comprehensive Guide to Wheel Hub Motorcycle Casting Molds: Types and Materials

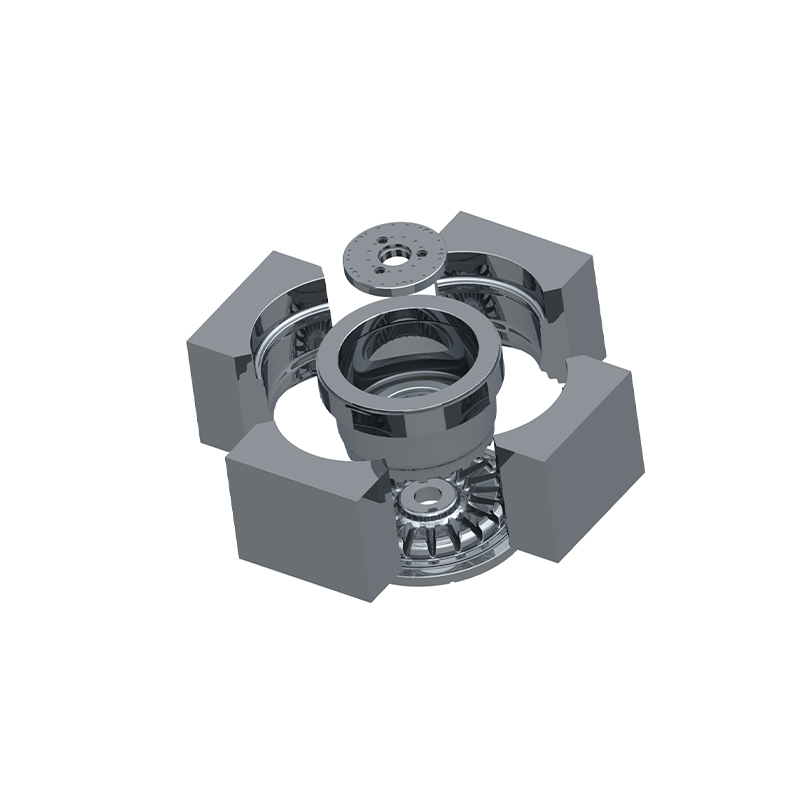

What is a Wheel Hub Motorcycle Casting Mold?

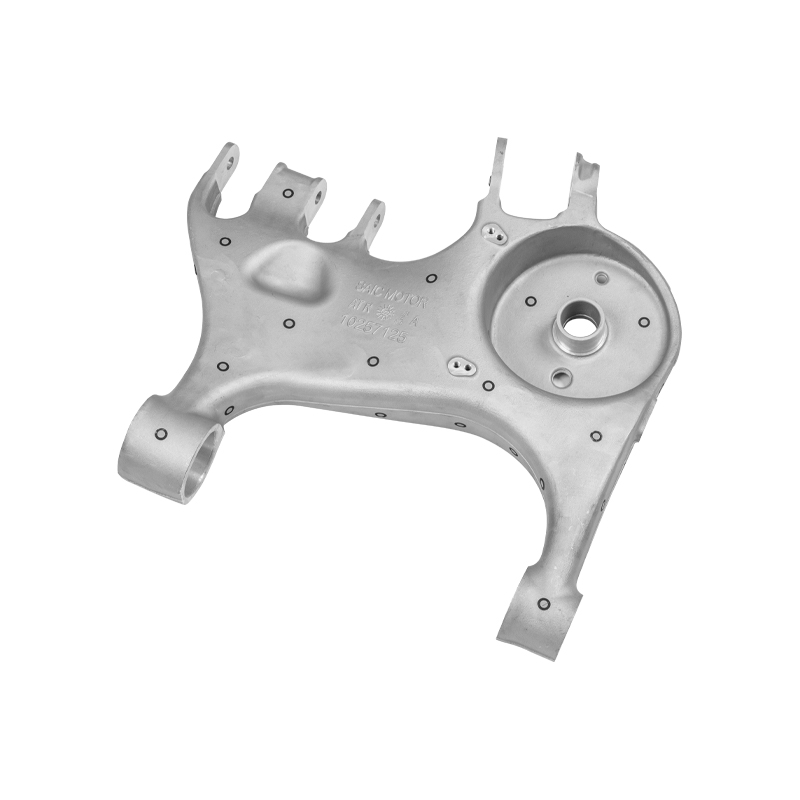

A wheel hub motorcycle casting mold is a tool used to cast molten metal (such as aluminum, magnesium or iron) into a motorcycle wheel hub. The design and selection of the casting mold is critical to the quality of the final product. The casting process forms a wheel hub with a predetermined shape and size by injecting molten metal into the mold. By precisely controlling the design and material of the mold, higher strength, better surface quality and lighter weight can be achieved.

Types of Wheel Hub Motorcycle Casting Molds

Sand Casting Molds

Lower cost: Suitable for small and medium batch production, especially for production projects with limited budgets.

Flexible design: Able to manufacture parts with complex shapes and suitable for a variety of design requirements.

Adaptable: Can be used for a variety of metal materials, such as aluminum alloys, copper alloys, cast iron, etc.

Easy to operate: The technology is simple to use and easy to operate, especially for small and medium-sized manufacturers.

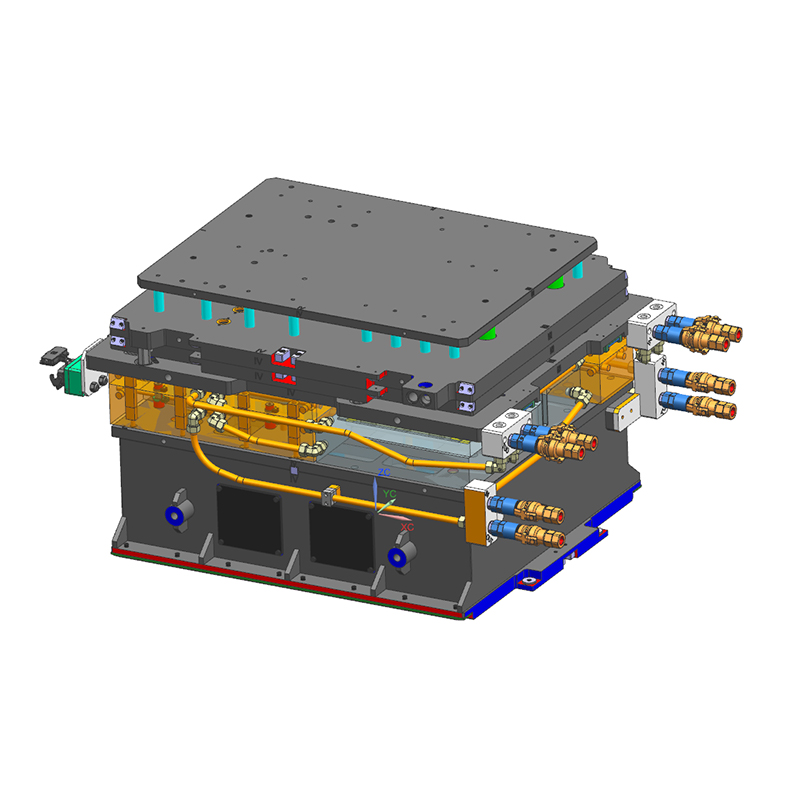

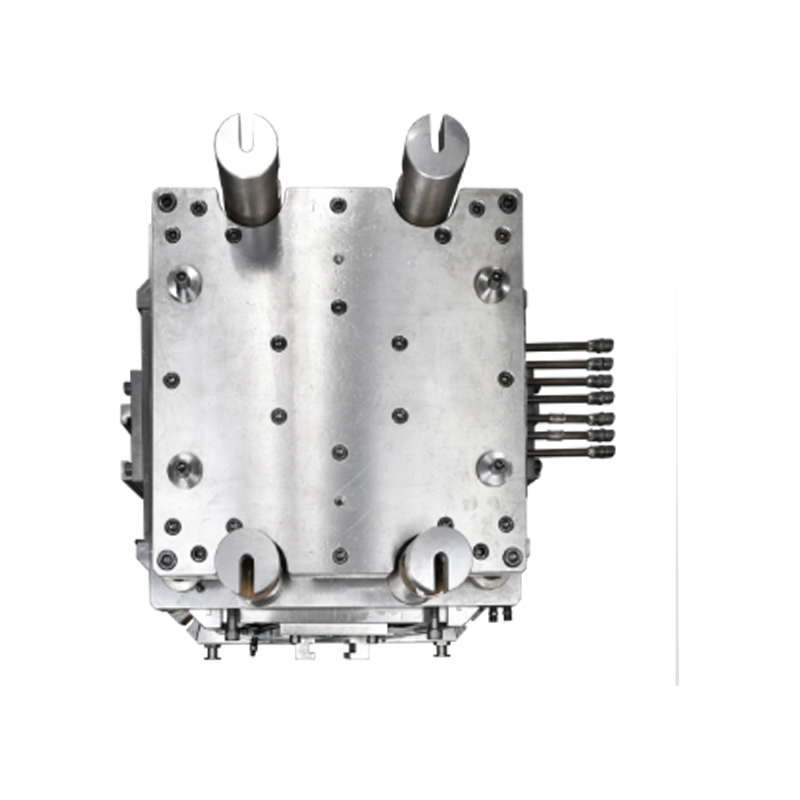

Die Casting Molds

High precision: Die casting can provide extremely high dimensional consistency and surface smoothness, reducing subsequent processing work.

Fast production speed: Suitable for large-scale production, high-precision parts can be manufactured quickly.

High strength: High-strength parts are formed by injecting molten metal at high pressure.

Good surface quality: The resulting parts have a smooth surface, reducing the need for subsequent surface treatment.

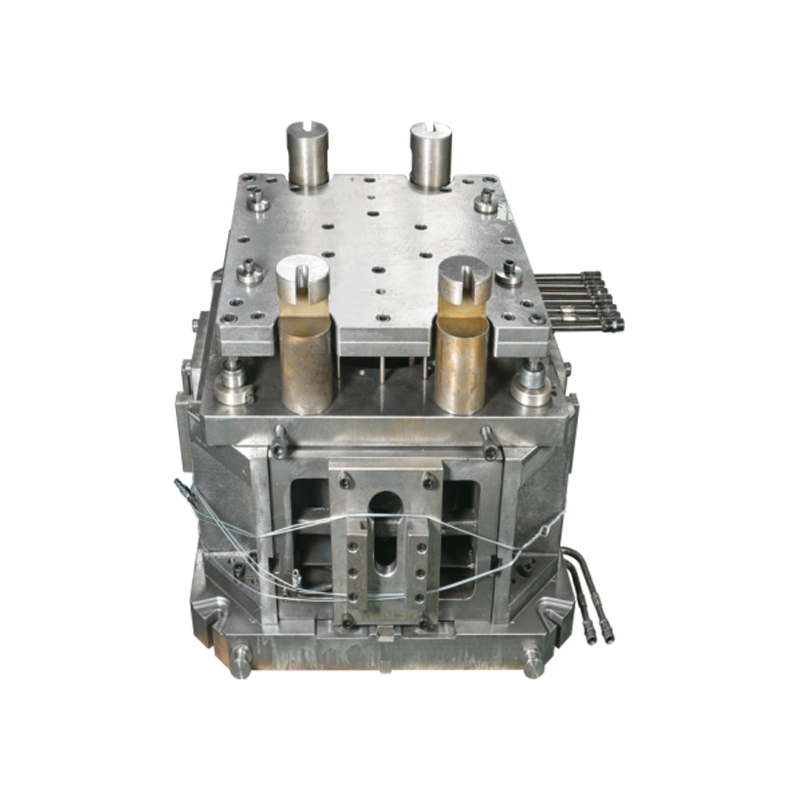

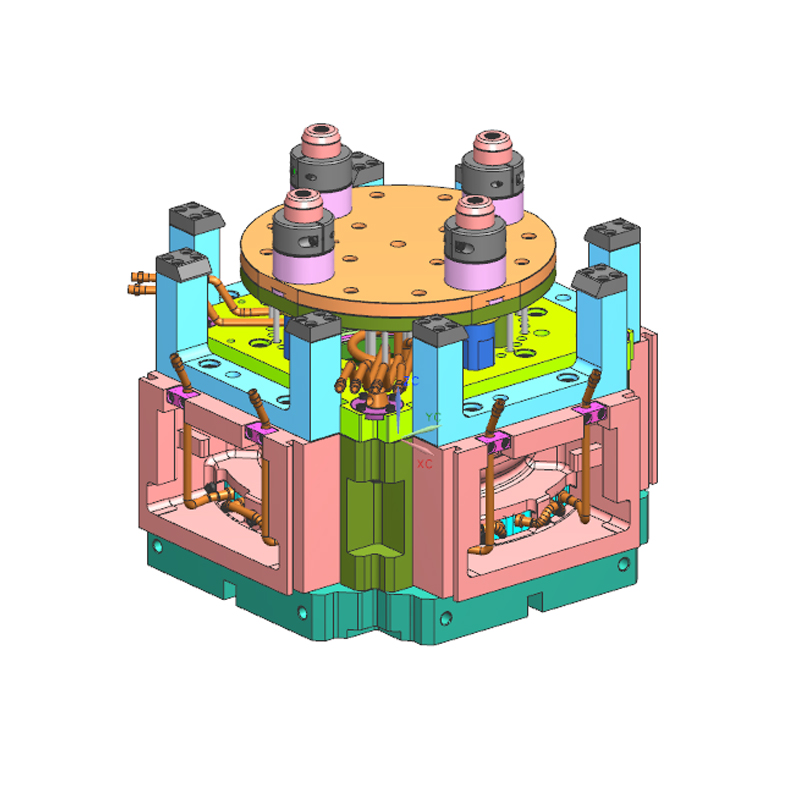

Investment Casting Molds

High precision: Precision casting can manufacture very complex and delicate parts with very high dimensional accuracy.

Smooth Surface: This technology requires almost no post-processing, saving time and money.

Complex Design: Able to cast complex geometries, suitable for high-end, custom and specialty parts.

High Performance: Able to produce high-performance, high-quality motorcycle parts, especially for high-end motorcycles.

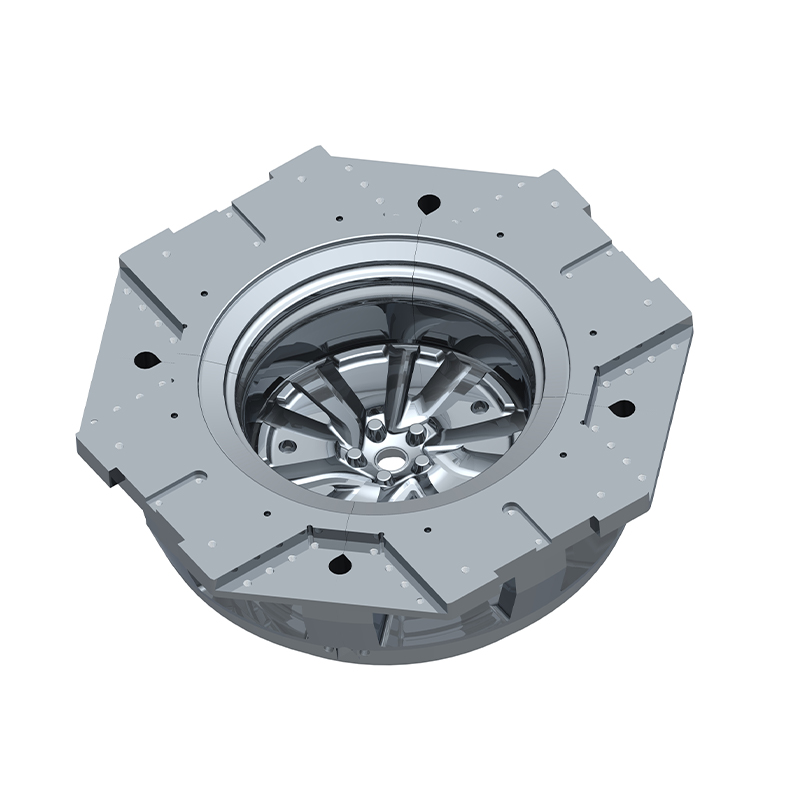

Permanent Mold Casting

Good Surface Quality: Permanent mold casting has a smoother surface and usually does not require much post-processing.

Durable Mold: Molds can be reused, which is very suitable for medium-scale production.

Medium-volume production: This casting method is very suitable for producing medium-volume parts.

Improved Production Efficiency: It can reduce the need for disposable molds in the production process and improve production efficiency.

Materials Used in Wheel Hub Motorcycle Casting Molds

Aluminum Alloys

Lightweight: Aluminum alloys have a low density, which helps to reduce the overall weight of the motorcycle and improve handling and performance.

Corrosion Resistance: Aluminum alloys have good oxidation and corrosion resistance and are suitable for use in various weather conditions.

Excellent Processability: Aluminum alloys are easy to process and can achieve precise dimensions and complex shapes.

Strength and toughness: With good strength and toughness, it provides stable performance in motorcycle wheels.

Magnesium Alloys

Extremely light: Magnesium alloys are the lightest materials of all metals, which can significantly reduce the weight of motorcycles, enhance speed and performance.

High strength: Although magnesium alloys are light, they are very strong and suitable for high-performance and racing motorcycles.

Corrosion resistance: After proper treatment, magnesium alloys can resist corrosion and increase the service life of components.

Good processability: It can be easily processed into various complex shapes and is suitable for high-precision requirements.

Cast Iron

High strength: Cast iron has very good hardness and impact resistance, which is suitable for motorcycles carrying large loads.

Strong wear resistance: It has very excellent wear resistance, which allows the motorcycle to maintain good performance during long-term use.

High temperature resistance: It can work at high temperatures and is suitable for some high-performance or heavy-load motorcycles.

Good stability: Cast iron can maintain high stability and strength even under extreme conditions.

Steel Alloys

Extreme Strength: Steel alloys have very high strength and are suitable for motorcycle parts that are subject to high loads and high impact.

Wear Resistance: Steel alloys are very resistant to wear and are suitable for motorcycle parts that require high durability.

High Temperature Tolerance: Steel alloys can withstand high temperatures without losing strength due to high temperatures, which is suitable for some high-performance motorcycles.

Good Processability: Steel alloys are stable during processing and are suitable for a variety of processing methods.

Composites

Ultra-light: Composites are much lighter than metals and can significantly reduce the overall weight of the motorcycle, improve acceleration performance and handling.

High Strength: Composites are generally very strong and can provide high-performance motorcycle parts.

High Corrosion Resistance: Composites have a natural ability to resist corrosion, which is particularly suitable for motorcycles exposed to moisture or salt water for a long time.

High Customization: Composites can be customized according to different needs and are suitable for the manufacture of high-end or special motorcycles.

English

English 中文简体

中文简体