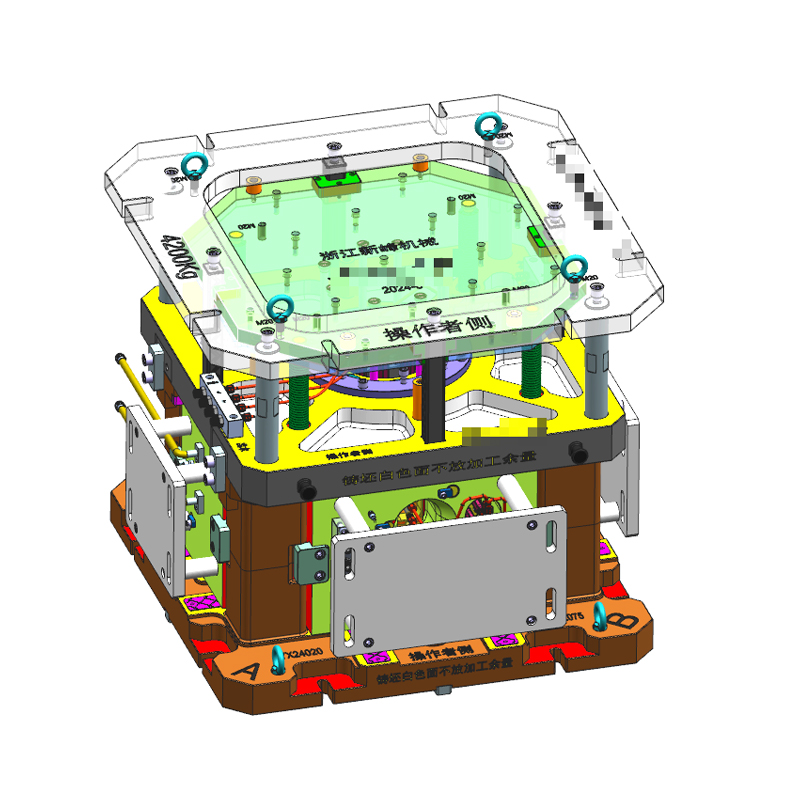

We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

How Structural Parts Casting Molds Improve Manufacturing Efficiency

Structural parts casting molds have revolutionized manufacturing by offering various advantages that improve both the speed and quality of production processes. In industries such as automotive, aerospace, and heavy machinery, casting molds are invaluable tools for creating complex, high-precision parts.

1. Reduction in Production Time

One of the key benefits of using structural parts casting molds is the significant reduction in production time. Once a mold is designed and produced, it can be reused to produce identical parts for a long period without requiring much additional work. This "repeatability" is a massive time-saver in manufacturing processes.

For instance, in die casting, the molten metal is poured into a reusable metal mold and allowed to cool, forming a part. This process is much faster than traditional methods like forging or machining, which often require separate processes for each individual part. The cycle time for casting can be very short, with some molds able to produce a part in a matter of minutes.

By reducing the time it takes to produce each part, manufacturers can significantly increase their output and reduce the need for long setup times, making their production lines more efficient and cost-effective.

2. Cost Savings Through Material Optimization

Casting molds are designed to use material more efficiently compared to other manufacturing processes, such as machining or subtractive manufacturing. The casting process creates parts in a shape that is very close to the final design, meaning less material is wasted.

In traditional machining, large blocks of material are cut down to shape, resulting in a lot of waste material, which can be costly. With casting, the material is typically poured into the mold in a liquid state, filling only the cavity where it is needed, reducing scrap significantly.

For example, in sand casting, after the mold is made, the sand is reused multiple times, minimizing waste. In die casting, molten metal is injected into the mold under high pressure, ensuring that only the exact amount needed for the part is used.

Scrap from defective parts can often be melted down and reused for future castings, further reducing material costs. This ability to optimize material use directly contributes to cost savings, making casting molds an attractive option for many industries.

3. Consistency and Quality Control

A primary challenge in manufacturing is maintaining consistent quality across large volumes of parts. Structural parts casting molds provide a high level of consistency because the molds themselves are designed with extremely tight tolerances. Once the mold is produced, the same part can be produced repeatedly with minimal variation.

Casting molds ensure that each part is nearly identical to the others, reducing the need for extensive quality control or rework. This consistency is particularly important in industries such as aerospace, where parts must meet very specific standards for safety and performance. Small variations in part dimensions can lead to poor fit or functionality, which can be dangerous.

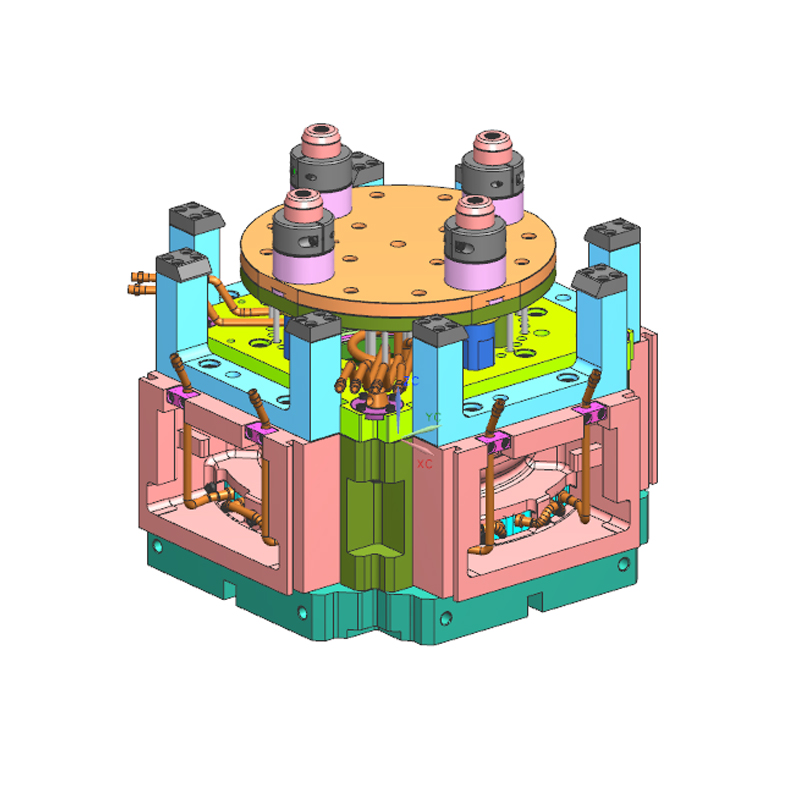

Automated casting systems reduce the potential for human error, as much of the process is controlled by machines. For instance, in die casting, the molten metal is injected into the mold using automated systems that ensure accurate flow and pressure. This automated process enhances precision and reduces the chances of defects.

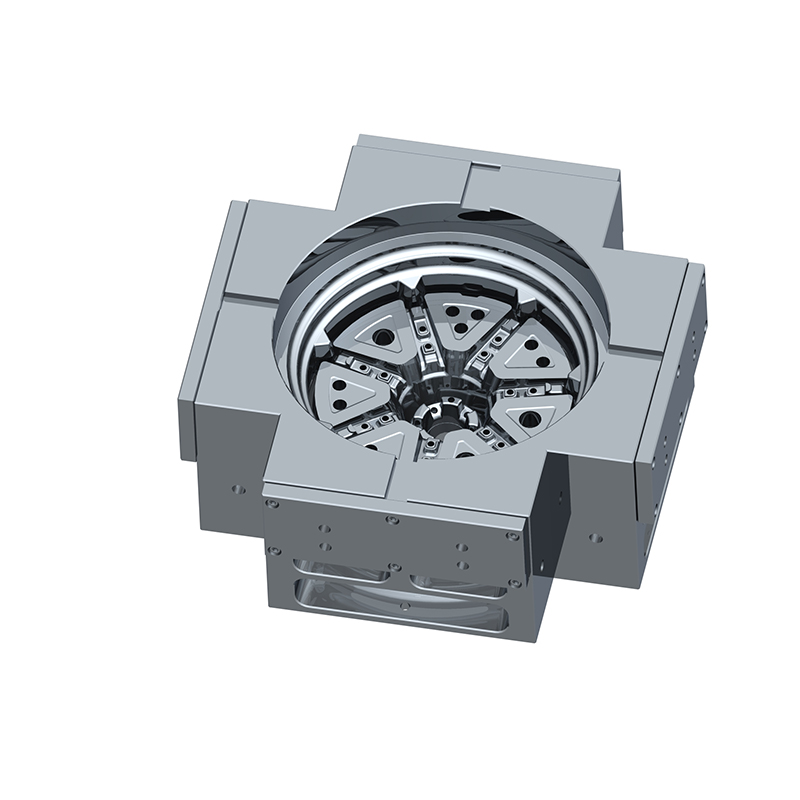

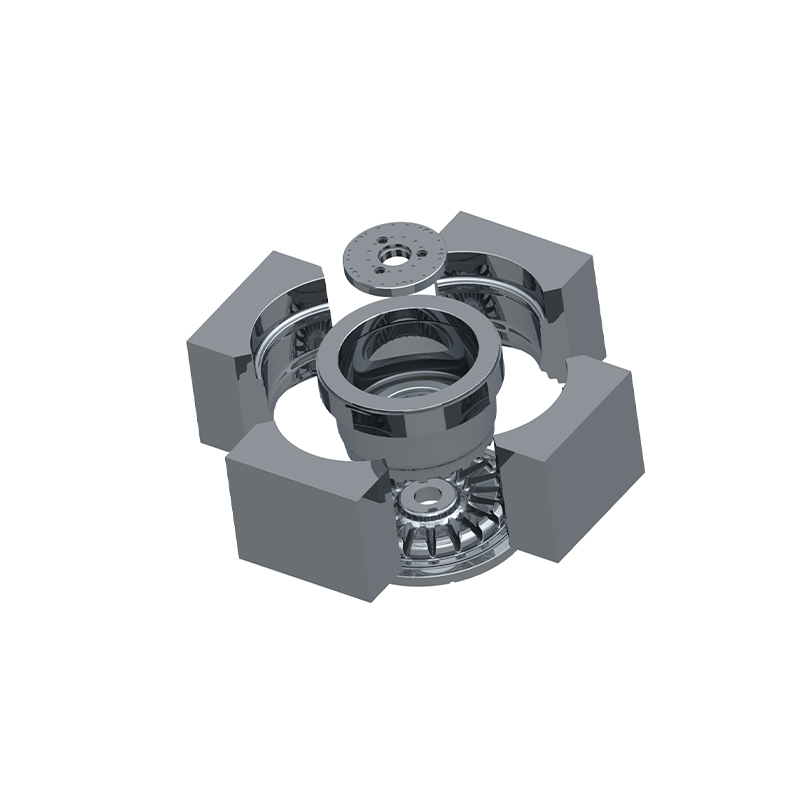

4. Complex Geometries with Minimal Tooling

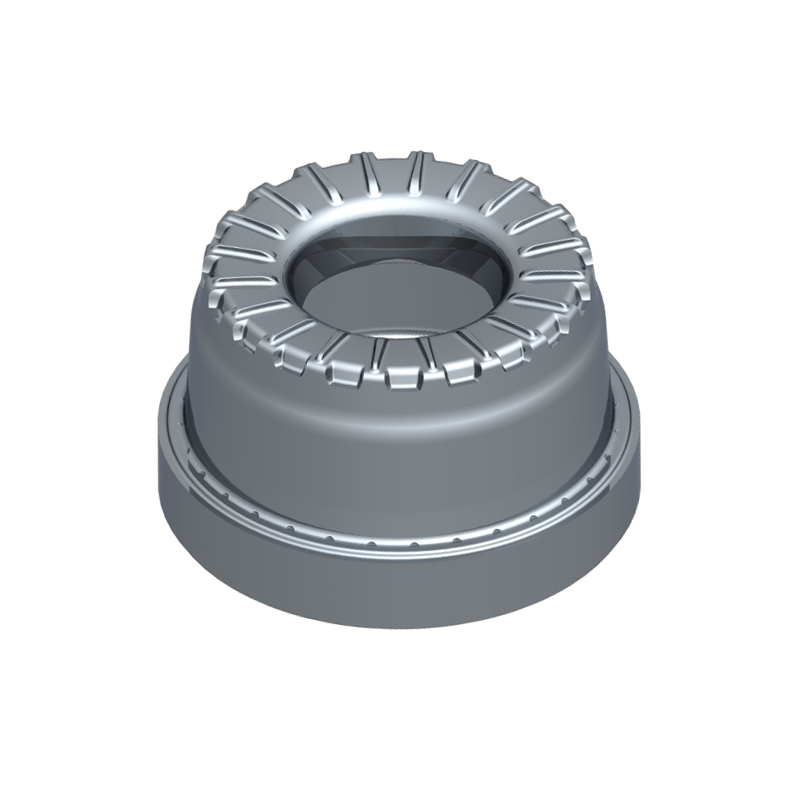

One of the key advantages of casting molds is their ability to create parts with complex shapes, which may be difficult or impossible to achieve with traditional manufacturing methods. Structural parts casting allows manufacturers to produce intricate geometries, such as internal cavities, undercuts, and detailed patterns, with minimal additional tooling.

For example, in sand casting, the mold is made by packing sand around a pattern, which can be easily shaped to include very complex features. Similarly, in die casting, molds can be designed with multiple cavities and cores to produce multi-featured parts in a single step.

This capability to produce complex designs in one process reduces the need for additional machining or assembly steps that would typically be required with other manufacturing techniques. By consolidating multiple steps into one casting operation, manufacturers can save both time and money, further increasing efficiency.

5. Versatility in Material Options

Casting molds are highly versatile in terms of the types of materials they can work with. This versatility allows manufacturers to select the best material for each application based on factors such as strength, weight, corrosion resistance, and cost.

Common materials used in structural parts casting include metals such as aluminum, steel, iron, and more specialized alloys like titanium or magnesium. Each of these materials offers different benefits, making casting molds suitable for a wide range of applications across various industries.

For instance, in the aerospace industry, lightweight but high-strength alloys are often used, while in automotive manufacturing, steel or aluminum might be chosen for their durability and cost-effectiveness.

6. Scalability for Mass Production

Casting molds are particularly advantageous when it comes to scaling up production for mass manufacturing. Once the mold is created, it can be used to produce thousands or even millions of parts with minimal additional setup. This makes casting molds ideal for industries that require high-volume production, such as the automotive or consumer goods industries.

The ability to rapidly scale up production is crucial for meeting market demand and keeping up with competition. For example, in die casting, the mold can be designed to accommodate a large number of parts in a single cycle, increasing the production rate while maintaining the consistency of each part.

Casting molds can be used to produce parts with high throughput, making them a critical tool in ensuring that supply chains are not disrupted by bottlenecks in production. As demand increases, manufacturers can increase the speed of casting cycles, leading to faster turnaround times and reduced lead times.

7. Energy Efficiency

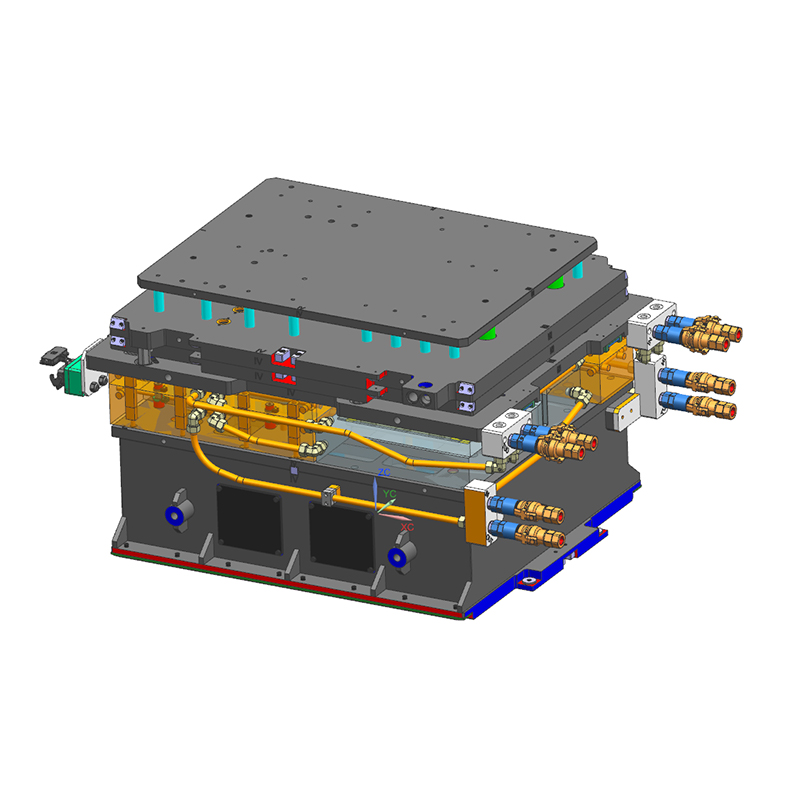

In casting processes such as sand casting and die casting, the molds are often designed to optimize the use of energy. For instance, preheating the mold or utilizing molds that retain heat for longer periods helps reduce the energy required to heat up the material each time it is poured.

In die casting, the mold itself can be designed with cooling channels that ensure rapid and uniform cooling, which not only speeds up the solidification process but also helps optimize the energy used. This energy efficiency not only reduces operating costs but also contributes to sustainability by lowering energy consumption.

As energy costs continue to rise, manufacturers increasingly rely on energy-efficient casting molds to reduce production costs and minimize their environmental impact.

8. Reduced Post-Processing Requirements

One of the major advantages of casting is that it often requires less post-processing compared to other manufacturing methods. Because casting molds can be made to very tight tolerances, the parts produced are often close to their final shape and size. This means less need for finishing processes such as machining, grinding, or polishing.

For example, in precision casting, the parts may only need to be cleaned and tested before being sent to the next stage of production. In contrast, parts made by machining often require additional steps to achieve the desired surface finish or dimensional accuracy.

This reduction in post-processing saves both time and money, allowing manufacturers to focus resources on other aspects of production. In some cases, it may even eliminate the need for costly secondary operations altogether, further improving efficiency.

9. Improved Supply Chain Efficiency

Casting molds help streamline the supply chain by providing manufacturers with the ability to quickly produce large batches of identical parts. By having a consistent and repeatable process, manufacturers can maintain inventory levels that are well-aligned with market demand.

This leads to shorter lead times and faster response to market changes, as manufacturers can produce parts on demand. Because casting molds reduce the need for multiple processes, parts can be produced more efficiently, helping to eliminate delays caused by lengthy production times.

In industries that require just-in-time (JIT) manufacturing or rapid prototyping, casting molds offer a way to meet production schedules with greater accuracy and reliability.

10. Customization and Flexibility in Design

Finally, casting molds provide manufacturers with greater flexibility in part design. Engineers can create customized features and complex shapes without worrying about tooling limitations. This flexibility allows designers to test new concepts and modify part designs without incurring significant additional costs or delays.

For example, in die casting, the mold design can be easily modified to include additional features such as internal cooling channels, ribs for strength, or mounting points for assembly. This adaptability is crucial in fast-moving industries where product designs evolve quickly.

With casting molds, manufacturers can meet specific customer demands and stay ahead of competitors by producing customized parts efficiently.

English

English 中文简体

中文简体