We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

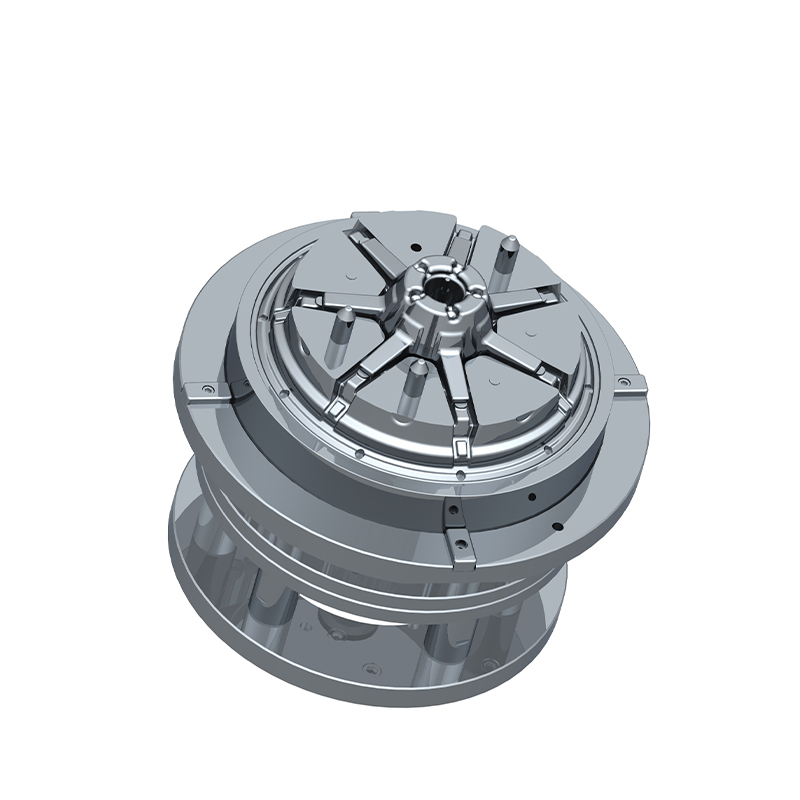

Aluminum Alloy Wheel Mold Manufacturing Process Full Analysis

Aluminum alloy wheels play an extremely important role in the modern automobile industry. With the acceleration of the trend of lightweight automobiles, aluminum alloys have gradually replaced traditional steel wheels and become the mainstream of the market due to their advantages such as light weight, high strength and corrosion resistance. To produce high-quality aluminum alloy wheels, the design and manufacture of molds are an indispensable core link. The mold not only determines the appearance accuracy and structural performance of the wheel hub, but also directly affects production efficiency and cost control. Mastering the mold manufacturing process is of vital importance to the entire aluminum alloy wheel industry chain.

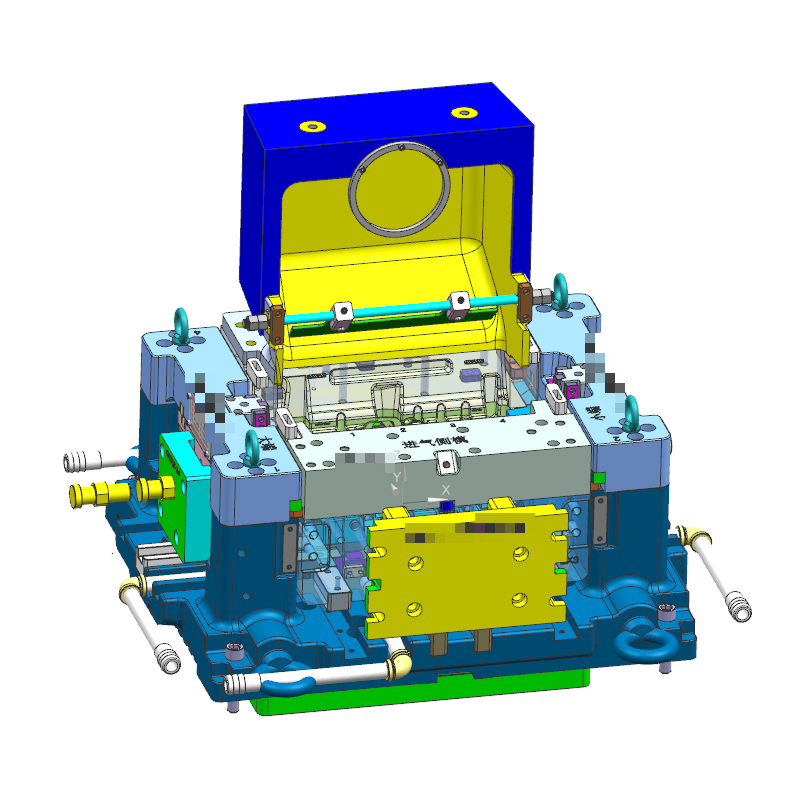

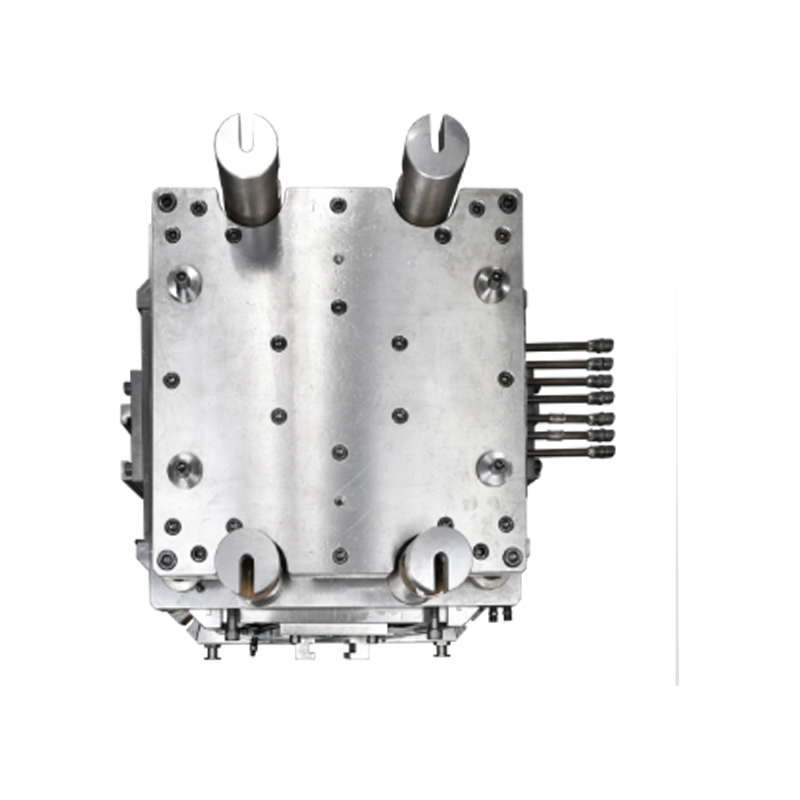

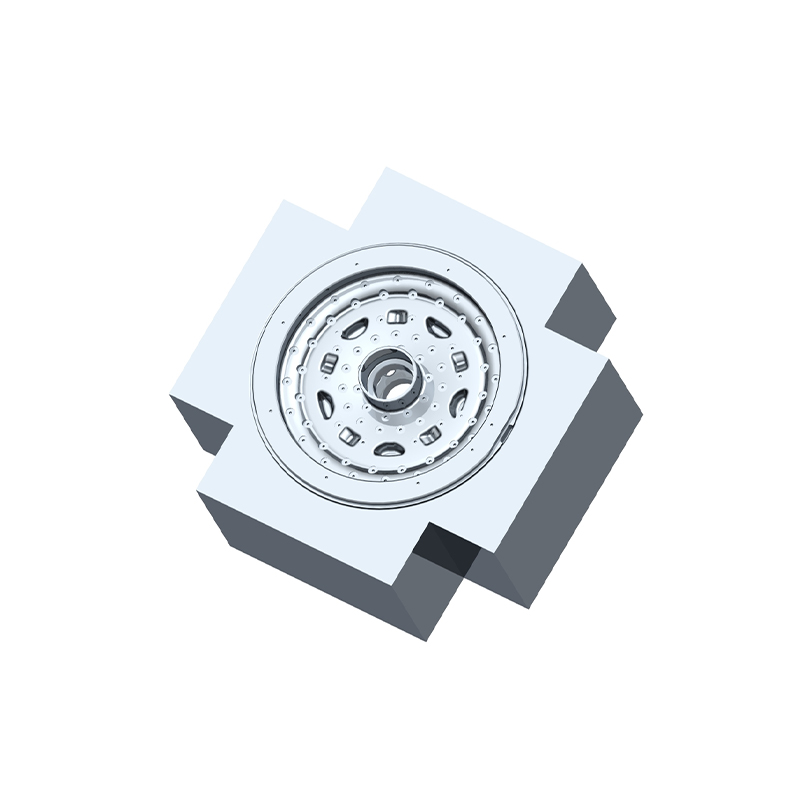

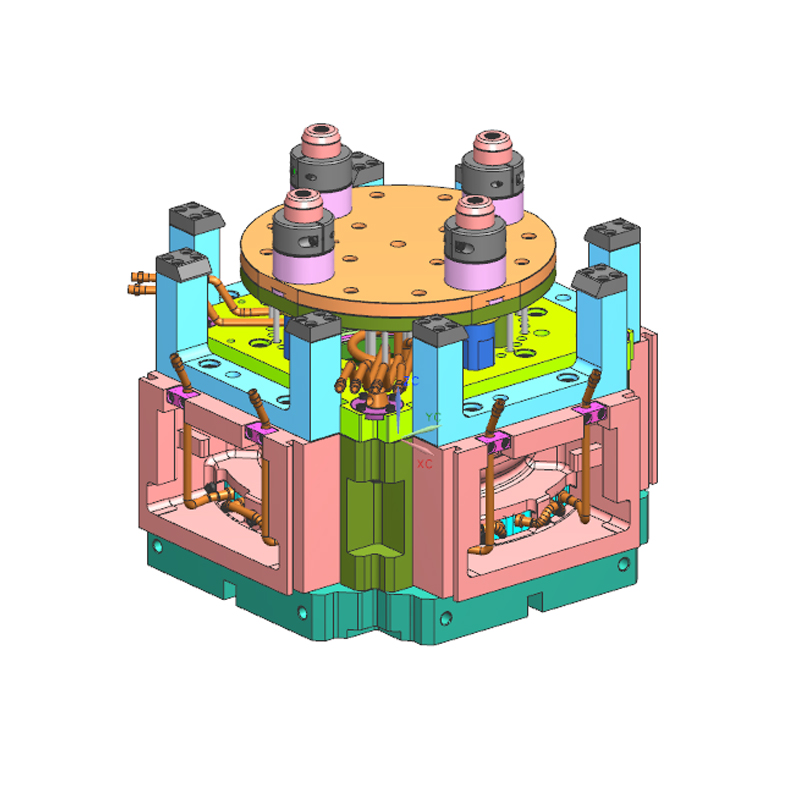

1. Structural characteristics of aluminum alloy wheel molds

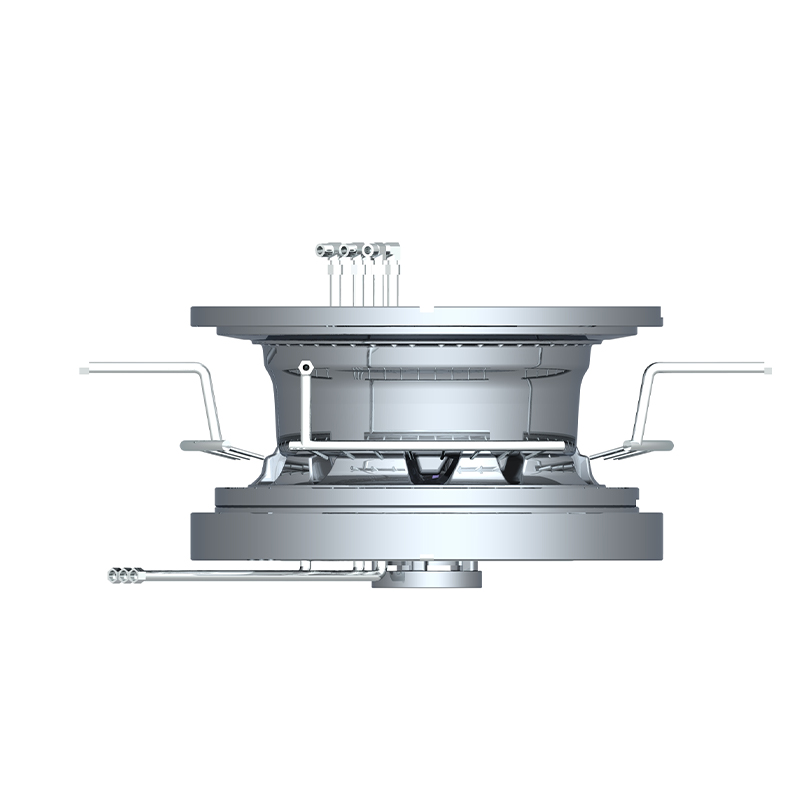

Aluminum alloy wheel molds are usually used for low-pressure casting or gravity casting processes, and their structural design must take into account strength, durability and precision. The mold is mainly composed of an upper mold, a lower mold, a core, a runner system, a cooling system and an exhaust system. Since aluminum liquid has strong fluidity at high temperatures, but is also prone to oxidation and shrinkage, the mold design must ensure that the casting is fully filled and minimize defects such as pores and shrinkage. In order to achieve a high-precision wheel hub shape, the cavity surface needs to be precisely processed and polished to ensure that the surface roughness meets industry standards. The layout of the cooling system is crucial, as it directly affects the cooling rate and internal structure performance of the casting. Reasonable cooling channels can prevent thermal cracking and deformation. The mold material generally uses high-strength hot working die steel (such as H13, SKD61), and is quenched and tempered to ensure wear resistance and thermal fatigue resistance. In general, the structure of the aluminum alloy wheel mold must not only meet the molding accuracy, but also have a long service life to reduce the frequency of mold replacement and production costs.

2. Manufacturing process

The manufacturing process of aluminum alloy wheel molds is complex and delicate, and usually includes the following steps:

Mold design: First, a three-dimensional model is established through CAD software (such as UG, SolidWorks), and CAE software is used to simulate fluidity and cooling to ensure that the pouring system is reasonable and the stress distribution is uniform.

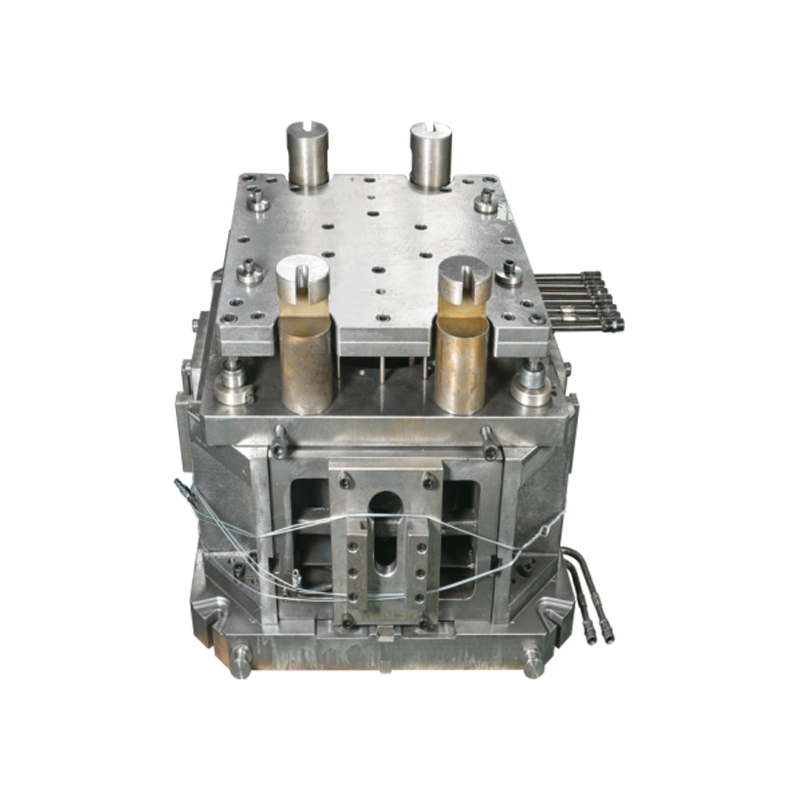

Material preparation: High-quality hot working die steel is selected, and forging and tempering treatment are performed to improve the material's structure density and mechanical properties.

Rough machining: The mold blank is rough machined using a CNC milling machine to form a basic cavity contour.

Heat treatment: Quench and temper the mold to achieve the required hardness (generally HRC44-48) and toughness.

Finishing: Complete the detailed structure through high-speed CNC machining and electrospark machining (EDM), and ensure that the tolerance is within ±0.02mm.

Surface treatment: Polishing, nitriding or chrome plating are used to improve surface hardness and oxidation resistance.

Assembly and debugging: Assemble the various parts and test the mold, detect the product size and surface quality, and correct the mold if necessary.

The entire process requires not only precise control of each step, but also advanced processing equipment and strict quality inspection methods to ensure the final mold performance.

3. Key technical points

The manufacturing of aluminum alloy wheel molds is not only a simple mechanical processing, but also includes many key technical control points. Dimensional accuracy control, the error of the mold cavity is usually required to be within ±0.02mm, otherwise it will directly affect the balance and safety of the wheel hub. The design optimization of the cooling system is particularly important. Reasonable cooling water channels can reduce mold thermal stress, prevent thermal fatigue cracking, and improve the grain structure of castings and mechanical properties. Mold surface treatment is also one of the core links. Through nitriding, PVD coating and other technologies, wear resistance can be improved and service life can be extended. Processing deformation control should also be considered in mold manufacturing. By reasonably arranging the rough and fine processing sequence and process parameters, dimensional deviation caused by stress release can be avoided. With the development of the industry, more and more companies are adopting digital manufacturing and online detection technology to achieve full-process monitoring and lean production to ensure that the mold achieves high precision and high stability.

4. Common problems and solutions

During the use of aluminum alloy wheel molds, a series of technical problems are often encountered. For example, mold cracking is one of the common faults, which is mainly caused by thermal stress concentration or poor material quality. The solution includes optimizing the cooling design, selecting high-toughness mold steel and performing reasonable heat treatment. Another type of problem is surface defects of castings, such as pores, cold shuts, shrinkage, etc., which are often caused by unreasonable design of the pouring system or poor exhaust. The solution is to optimize the runner through CAE simulation and add exhaust grooves. There is also the problem of mold wear too fast. Especially in high-pressure casting environment, the cavity surface is prone to failure due to erosion and oxidation. Nitriding or PVD coating can be used to enhance wear resistance. Mold size deformation is also a common problem, which needs to be avoided by reasonably arranging the processing technology and increasing stress release annealing. If these problems are not handled in time, they will directly affect the appearance and mechanical properties of aluminum alloy wheels, and even cause safety hazards.

5. Future development trend

With the continuous advancement of intelligent, lightweight and environmentally friendly automobile industry, aluminum alloy wheel mold manufacturing is also developing in the direction of high-end and intelligent. Digital manufacturing has become an industry trend. Through digital twin technology, virtual verification of the entire process of design, processing and testing can be achieved, which greatly shortens the development cycle. Intelligent monitoring and predictive maintenance are emerging. During the operation of the mold, sensors can be used to monitor temperature, pressure and other data in real time, and potential faults can be warned in advance to avoid downtime losses. The concept of green manufacturing is also widely used, such as the use of energy-saving processing equipment, environmentally friendly coating technology, and reducing processing waste. One of the most promising technologies is additive manufacturing (3D printing), which shows great potential in complex mold waterways, local repairs and rapid mold trials, and is expected to completely change the traditional mold manufacturing model. In the future, combined with artificial intelligence and big data analysis, aluminum alloy wheel mold manufacturing will achieve higher precision, lower cost and longer service life.

English

English 中文简体

中文简体