We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

Market Trends and Future Development of Motorcycle Wheel Hub Casting Dies

1. Lightweighting Demand Drives Casting Mold Innovation

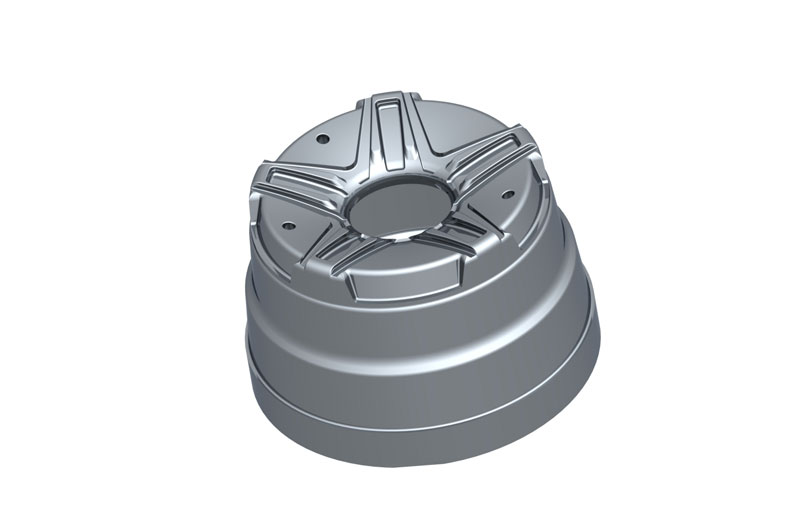

With increasingly stringent environmental regulations, particularly in Europe, the United States, and many Asian countries, motorcycle manufacturers face the dual pressures of improving fuel efficiency and reducing emissions. To meet these demands, motorcycle designs are increasingly lightweight. Key materials for lightweighting are typically high-strength metals such as aluminum alloys, magnesium alloys, and even titanium alloys. These materials offer high strength yet are relatively light, effectively reducing vehicle weight and improving fuel efficiency.

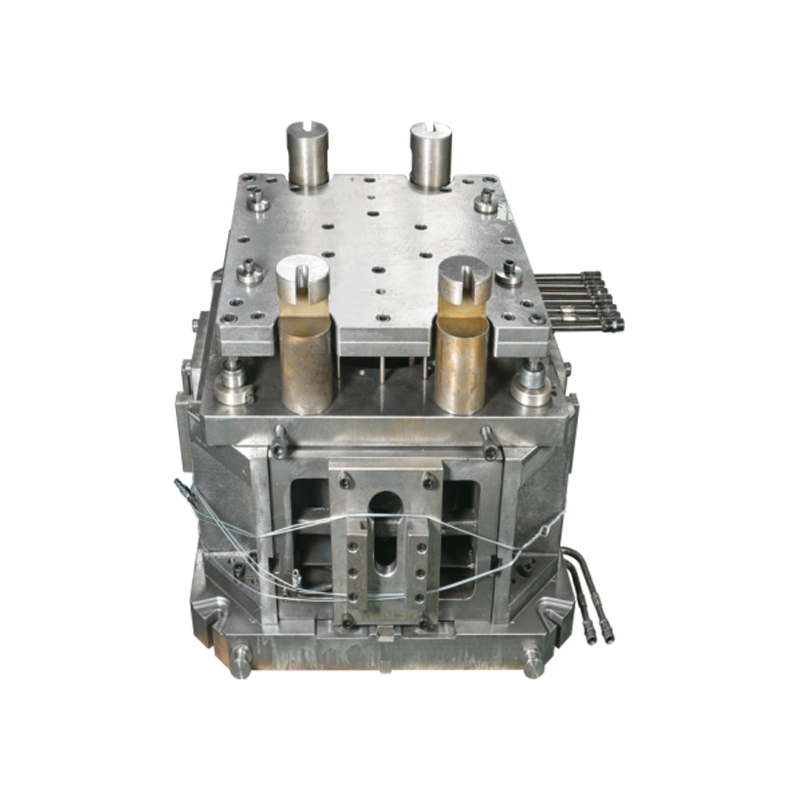

The use of lightweight materials places higher demands on the design and manufacture of casting molds. Traditional steel molds are often unsuitable for casting these high-strength materials. Therefore, casting mold manufacturers are innovating and developing molds suitable for these new materials. For example, they are developing molds using special alloy steels and high-temperature-resistant materials to enhance their strength and wear resistance. This not only extends mold life but also effectively improves production efficiency. As the lightweighting trend deepens, future innovations in motorcycle wheel casting molds will focus more on optimizing materials, processes, and mold wear resistance.

2. Application of Digital and Intelligent Technologies

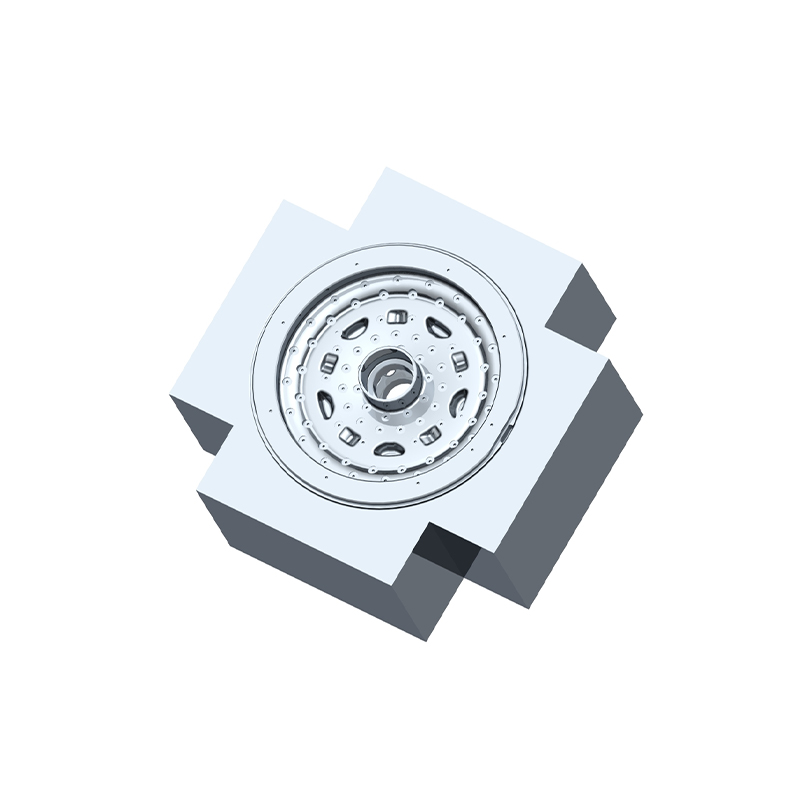

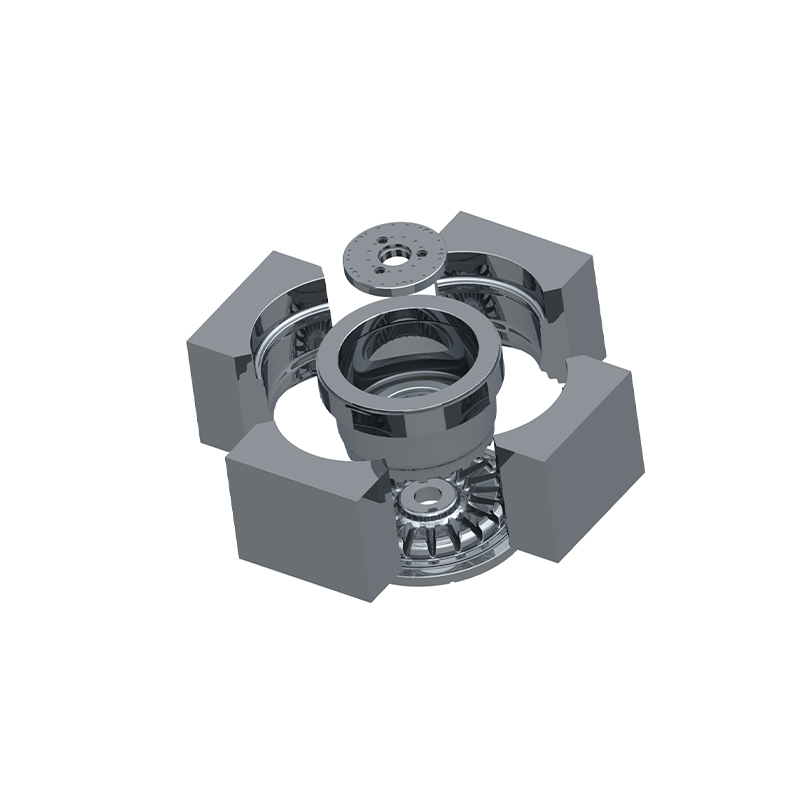

Modern casting technology is undergoing a transformation from traditional manual operations to intelligent and digital technologies. Computer-aided design (CAD) and computer-aided engineering (CAE) technologies have become essential tools for casting mold design. These technologies can accurately simulate factors such as heat flow and pressure during the motorcycle wheel casting process, enabling the foreseeable and remedy of potential casting problems.

The application of 3D printing technology has also brought unprecedented convenience to mold manufacturing. Through 3D printing, manufacturers can quickly produce prototype molds for field testing, thereby optimizing designs and reducing the time and cost required by traditional manufacturing methods.

Intelligent production systems have further improved the efficiency and precision of the casting process. Using intelligent sensing technology, machine learning, and data analysis, foundries can monitor every detail of the production process in real time, proactively identifying potential faults and correcting them. The widespread use of this intelligent technology will significantly improve mold precision and production efficiency, resulting in more stable quality and shorter production cycles for motorcycle wheel casting molds.

3. Continuous Optimization of Mold Materials

The material used in motorcycle wheel casting molds is a key factor in determining their durability, precision, and production efficiency. With the advancement of casting technology, the choice of mold material has also gradually evolved. In the past, steel was the most commonly used material for motorcycle wheel casting molds. However, with advancements in casting technology, manufacturers are beginning to adopt higher-performance alloy steels, heat-treated steels, and ceramic composites. These new materials offer enhanced resistance to high temperatures, corrosion, and wear, effectively extending mold life.

The use of high-performance materials not only improves mold durability but also enhances casting precision. For example, molds made of high-chromium alloy steel maintain higher strength at high temperatures, reducing mold deformation and ensuring the precision and consistency of each casting. Furthermore, future mold material research will focus on reducing mold weight, further improving ease of use and safety during production.

4. Increasing Demand for Customization and Small-Batch Production

With motorcycle consumers pursuing personalized and unique designs, the demand for customized motorcycle wheels is steadily increasing. Particularly in the high-end market, many consumers desire wheels tailored to their personal style, driving demand for customized wheel casting molds. Traditional mass production is being replaced by customization and small-batch production.

Customized production presents both opportunities and challenges for mold manufacturers. Meeting the diverse customer needs for wheel hub appearance, performance, and production cycle while ensuring mold quality has become a key focus of innovation for the company. For example, incorporating modular elements into mold design allows for rapid adjustments based on varying needs. Furthermore, leveraging digital technology improves the efficiency of small-batch production, ensuring that each product precisely meets customer specifications.

With the diversification of market demand, future mold production will become more flexible and intelligent, adapting to production orders of varying sizes and types.

5. The Rise of Green Casting Technology

Environmental protection has become a key trend in global manufacturing development, particularly in the foundry industry, where reducing environmental pollution has become a key concern. Traditional casting processes often generate large amounts of waste gas, wastewater, and waste residue, severely impacting the environment. Therefore, green casting technology has emerged as a key to future development.

Green casting involves more than just environmentally friendly improvements to the production process; it also includes selecting environmentally friendly mold materials and using low-pollution coatings and coolants. For example, using water-based paints instead of traditional oil-based paints reduces harmful gas emissions. Furthermore, using renewable and recyclable foundry sand reduces resource waste. Energy consumption during the casting process is also subject to strict control. By optimizing production processes, improving energy efficiency, and investing in energy-saving equipment, foundries can reduce their energy dependence and lower production costs. Green casting technology not only helps reduce environmental pollution but also helps companies lower compliance costs amid increasingly stringent environmental regulations.

6. Competition and Opportunities in a Global Market

The motorcycle industry is experiencing a wave of globalization, particularly with the rise of emerging markets in Asia, Africa, and Latin America. This presents enormous growth potential for the motorcycle wheel casting mold market. For example, rapid economic development in India and Southeast Asia has driven increased demand for motorcycles, making them an essential means of transportation in these regions.

This global market presents both opportunities and intensified competition. Demand, design requirements, and production standards for motorcycle wheels vary across different countries and regions. Manufacturers need to adapt and innovate to meet the demands of these markets to seize market opportunities. Furthermore, with the gradual optimization of global supply chains and the facilitation of international trade, motorcycle wheel casting mold manufacturers can more easily enter the global market and expand their business scope.

7. The Prevalence of Automated Production Lines

The prevalence of automated production lines is revolutionizing the production of motorcycle wheel casting molds. Automation not only improves production efficiency but also significantly enhances product consistency and precision. Traditional casting processes rely heavily on manual labor, making errors prone to occur during production and compromising product quality. Automated production lines, on the other hand, utilize sophisticated control systems, robotic arms, and sensors to ensure that every wheel hub is produced to exacting standards.

Automation also effectively reduces labor costs, reduces worker workload, and improves production safety. With the addition of emerging technologies such as intelligent robots and 3D printing, future casting production lines will become even more intelligent, enabling full automation from design to production, significantly shortening production cycles and improving efficiency.

8. Research and Development to Enhance Mold Lifespan

To meet the high-frequency and high-intensity use demands of motorcycle wheel casting, extending the lifespan of casting molds has become a key R&D goal for manufacturers. Traditional molds are prone to wear, deformation, and cracking due to long-term use, which in turn impacts product quality and production efficiency. Manufacturers are prioritizing the development of mold materials with higher wear resistance and higher temperature resistance.

For example, using heat treatment to enhance mold surface hardness or using surface treatments such as nitriding and carburizing can effectively improve mold corrosion and wear resistance. By optimizing the cooling system of the mold and reducing the impact of temperature fluctuations on the mold, it is also an effective way to extend the life of the mold. In the future, with the emergence of new materials and continuous innovation in manufacturing processes, the life of the mold will be significantly improved, and companies can reduce the downtime and costs caused by mold damage.

English

English 中文简体

中文简体