We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

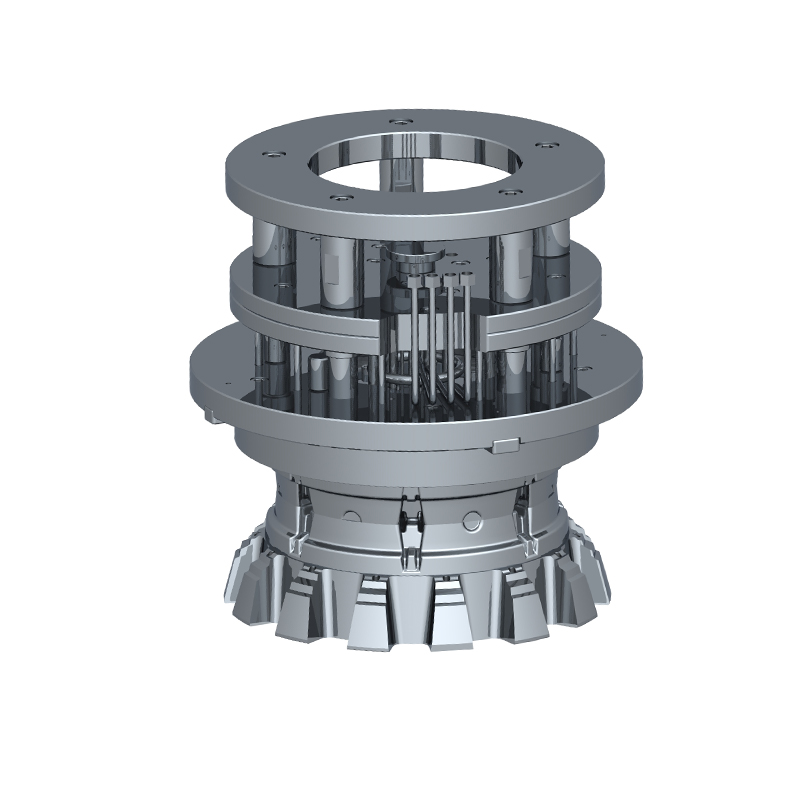

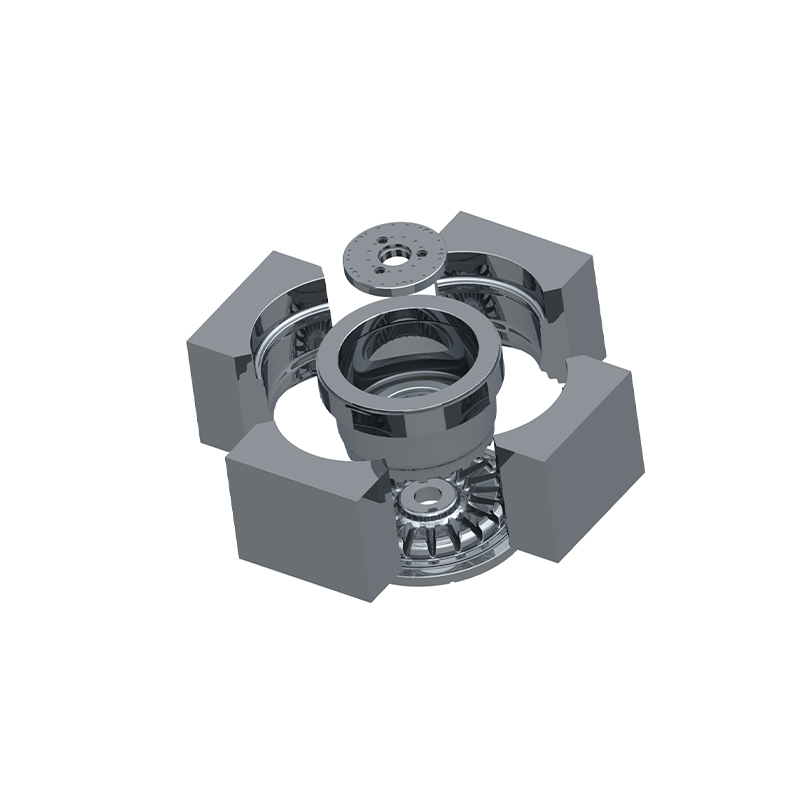

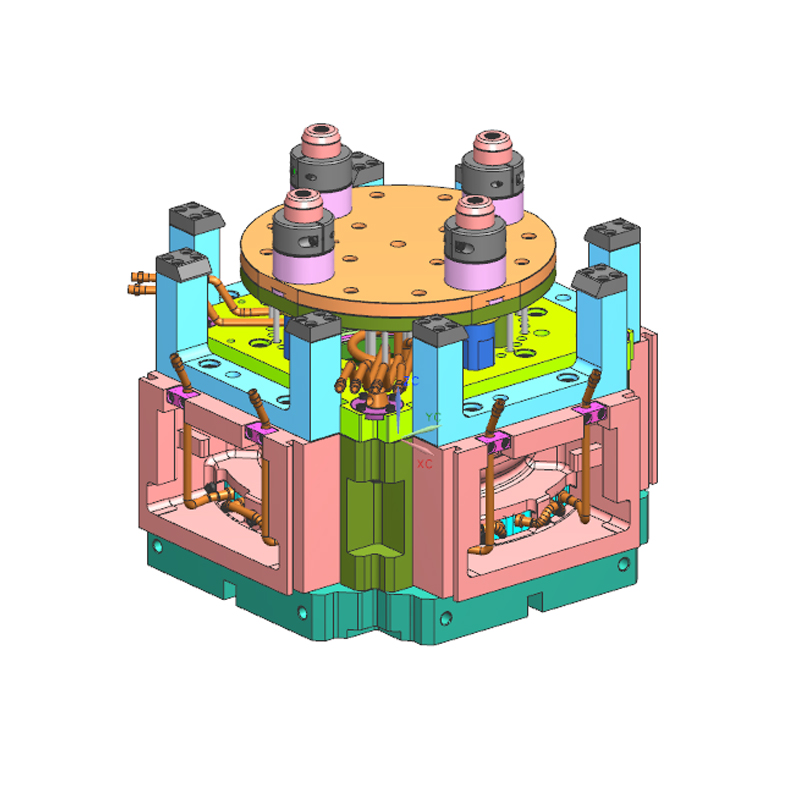

Wheel Hub Motorcycle Casting Mold Optimization Solution to Improve Casting Accuracy

Wheel Hub Motorcycle Casting Mold require high dimensional accuracy, dynamic balance, and mechanical strength. Systematic mold and process optimization can significantly reduce shrinkage, porosity, inclusions, and deformation, while minimizing the "blank accuracy + post-processing" factor, thereby reducing costs and improving yield. Casting simulation can identify and correct heat flow and solidification issues before production, avoiding extensive trial mold rework.

1) Use casting simulation during the design phase

Background and Purpose: Simulation can predict flow, cooling, air entrapment, insufficient feeding, and hotspot locations before mold fabrication and tryout, significantly reducing the number of tryouts and scrap rates. Many companies consider simulation a "must-do" to reduce risk and cost.

magmasoft.com

magmasoft.de

Performable Steps

CAD Cleanup: Remove unnecessary small chamfers and gaps; merge thin shell surfaces and confirm that the solid is free of gaps.

Modeling Materials and Boundary Conditions: Enter the alloy's temperature-dependent thermophysical properties (density, thermal conductivity, specific heat), set the mold/core box initial temperature, pouring temperature, pouring rate, and interfacial thermal resistance.

Meshing and Time Step: Refine the mesh in thin walls and details; perform mesh convergence analysis.

Perform "Virtual Design of Experiments (DOEs)": Perform parameter sweeps on gate location, pouring temperature, feeding size/location, mold temperature, and other parameters to identify the factors most influencing porosity, shrinkage, cold shut, and segregation. Key Output Explanation: Focus on the velocity field during filling (whether there is backflow/eddy current), the temperature field (hot spots), the final liquid area before and after solidification (feeding distance), and the predicted shrinkage and porosity contours.

Iteration: Adjust pouring/feeding/cooling according to the simulation results, and rerun the simulation until the heat flow/solidification sequence meets the directional solidification principle of "from far to near, from thin to thick."

Verification: Compare the temperature curves recorded for the first batch of trial molds with the measured thermal crack/porosity locations on the castings. If there are significant discrepancies, review the material data or boundary conditions for input errors.

2) Optimize the Gating and Feeding System

Key Principle: A good gating system ensures smooth filling (low surface turbulence), while the feeding system (riser) ensures that liquid metal is fed to critical areas during solidification, thereby avoiding shrinkage cavities and cracks. Directional solidification and the placement of side gates/feeding are key. Amazon Web Services, Inc.

magmasoft.de

Specific Actionable Solutions

Gating Process Design: Feed the melt flow from large/thick ribbed areas to thin-walled areas in a "reverse" fashion (i.e., solidify the thin, distal ends first and the thick, central areas last).

Stepped Gate (sprue → runner → gate): Set a stepwise contraction or expansion of the runner cross-section to control velocity and reduce spatter.

Use filters and bubble traps to reduce the entry of oxide inclusions into the mold cavity. MDPI research shows that adding filters, swirl gates, or trident gates can effectively reduce oxide inclusions and porosity.

MDPI

Riser Design: Use simulation to determine which areas are least solidified and where to place risers. Whenever possible, place risers in non-machined or easily removable locations to improve recovery (automatic optimization tools can be used to adjust riser shape and location).

magmasoft.de

Rules of Thing/Notes

Reduce abrupt cross-sections in the gating path (abrupt cross-sections can cause localized velocity jumps and turbulence). Prioritize localized chills (see point 6) or side injection for shrinkage-prone areas.

Common pitfalls: The gate is too far from the hotspot, preventing the feed from reaching it, or the riser cools too quickly to be effective—both of which can be predicted and corrected using simulation.

3) Control pouring temperature, mold temperature, and process window

Why important: Temperature directly affects metal fluidity, oxidation/hydrogen absorption rates, and the final solidification structure. Stable melt temperature and mold temperature are essential for ensuring repeatable accuracy. It is recommended to create an "alloy-mold temperature-pouring temperature" matrix in the process chart and record daily profiles.

Vietnam Cast Iron

MDPI

Recommended Parameters and Tools

Aluminum alloy pouring (rule of thumb range): Optimized temperatures are generally between 660–750°C (varies slightly between different alloys and processes). For most aluminum castings, the optimal pouring temperature is typically approximately 680–720°C. (Please refer to the manual for your specific aluminum alloy for details.) Vietnam Cast Iron

MDPI

Mold/Cavity Temperature (die casting/permanent mold): Typically maintained between 150–250°C (depending on mold material and alloy). Temperatures too low can cause cold shut/inadequate flow, while temperatures too high can accelerate mold wear and extend the cycle time.

CEX Casting

empcasting.com

Measurement and Control Methods: Install thermocouples on the melt and mold and record these temperatures (at least once per shift/per heat). Use an IR temperature gun or in-line thermocouples for secondary verification at critical steps. Establish temperature control alarms and batch records.

Process Control Recommendations

Establish upper/lower limits and a response plan (procedure for handling temperature deviations).

Melt holding time and chemical composition drift (especially for Sr, Mg, etc.) caused by multiple reheats should be recorded and incorporated into quality control procedures.

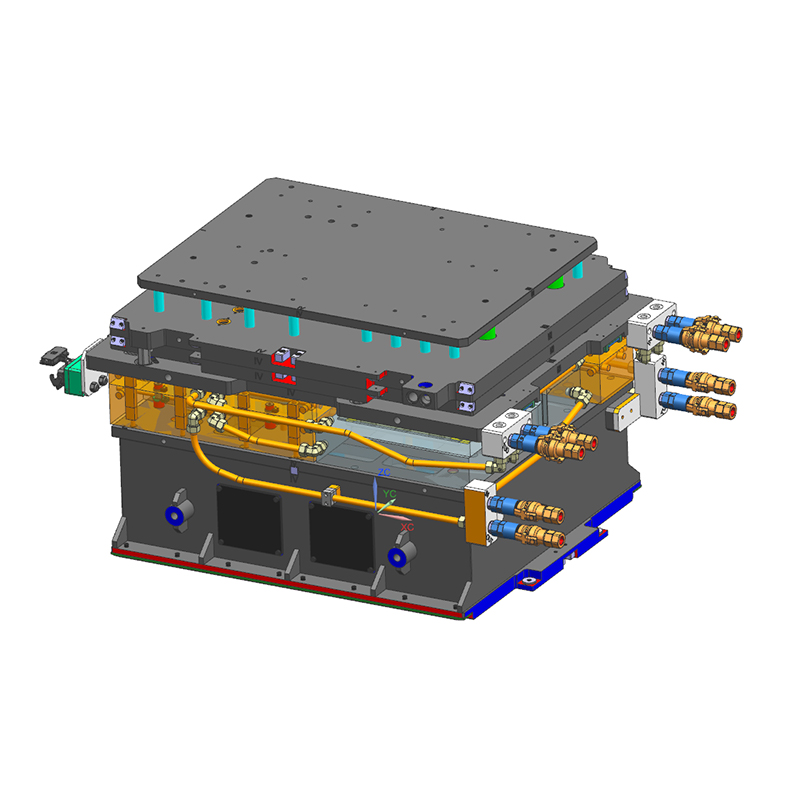

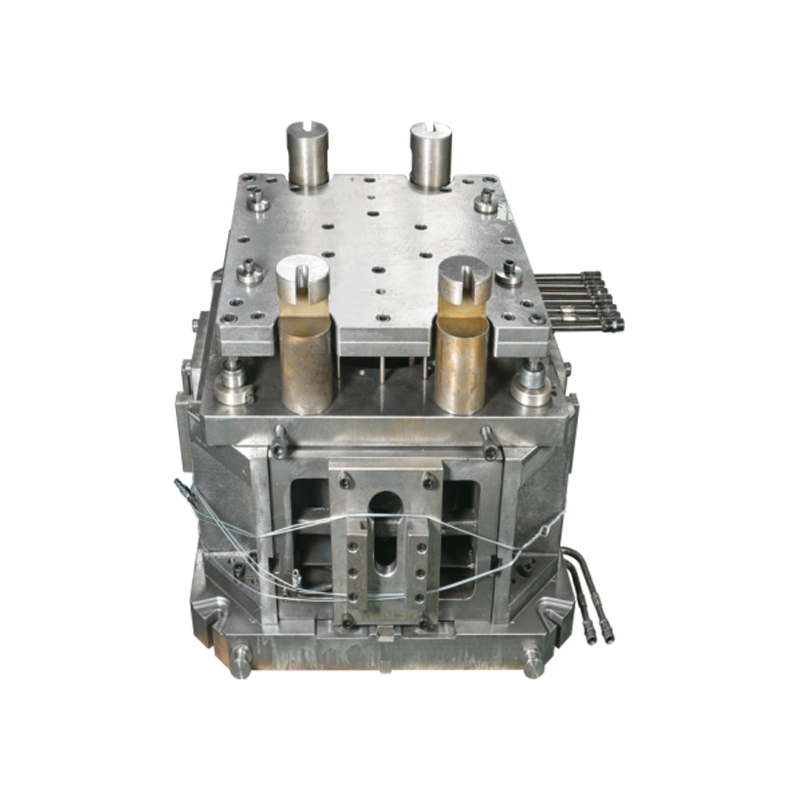

4) Select the appropriate casting process and mold material

Key decision points: For parts such as wheel hubs that require high precision and mechanical properties, high-pressure die casting (HPDC) or low-pressure casting (LPC) is preferred to achieve better density and surface quality. For small batches or complex cavities, precision sand molds or gravity constant-temperature molds are also suitable. Mold material (such as H13) and surface treatment directly affect mold life and surface finish.

sunrise-metal.com

magmasoft.de

Operational Details

Large batches with suitable shapes → Die casting is preferred (lower cost, dimensional stability, and good surface finish).

Small to medium batches with deep cavities → Low-pressure casting is an option to reduce porosity.

Mold material/surface treatment: H13 or high-strength mold steel with heat treatment (quenching and tempering), and nitriding/ceramic coating if necessary to reduce sticking and wear.

Consider post-machining reference positions during design (try to design critical mating surfaces on the same mold half to facilitate single-stage positioning).

5) Uniform Structural and Wall Thickness Design (Part Design Coordination)

Principle: Sudden changes in wall thickness can create local "hot spots," leading to uncontrolled directional solidification, inward shrinkage, or stress concentration. Uniform wall thickness combined with rounded corners can significantly reduce casting defects and distortion.

dfmpro.com

Design Key Points (Directly Applicable)

Minimize sudden changes in thickness: Use gradual transitions, increase chamfers, and increase corner radius (R ≥ 1.5–3 mm, depending on size).

When possible, achieve strength requirements through ribs rather than localized thickening. Rib thickness should generally not be significantly greater than twice the adjacent wall thickness.

For critical positioning/mating surfaces (bearing holes, flange surfaces), provide clear machining allowances in the mold (see point 8) and mark datums on the drawing.

6) Reducing Porosity and Inclusions: Melt Treatment + Vacuum/Low-Pressure Casting

Core Issue: Aluminum alloys readily dissolve hydrogen in the liquid state (which precipitates as pores upon condensation). Furthermore, oxide inclusions can enter the mold cavity with turbulent flow. Melt control and vacuum assistance are key measures.

moderncasting.com

empcasting.com

Actionable Items

Melt Treatment: Use a rotary degasser or inert gas displacement (argon/nitrogen) combined with melt stirring, and regularly use flux/slag to remove surface inclusions. Modern reports often cite rotary degassing as the standard practice.

moderncasting.com

Target Hydrogen Content: Typically, the target is approximately 0.2–0.3 mL H₂/100 g (or lower) to reduce porosity. (Acceptable values vary slightly between sources and should be calibrated based on experimental and measurement results.) migal.co

aluminiumceramicfiber.com

Vacuum/Low-Pressure Casting: Where feasible, using vacuum-assisted filling or vacuum die casting can significantly reduce air entrapment and porosity, especially for thin-walled, high-demand parts.

empcasting.com

Testing and Recordkeeping

It is recommended to test the hydrogen content of the melt using LECO/hydrogen content measurement equipment, either in-line or on a batch basis. X-ray spot checks should also be performed to verify the effectiveness of degassing/vacuum measures.

English

English 中文简体

中文简体