We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

Casting Molds Basic Guide: Complete Process from Design to Molding

I. Basic Concepts of Casting Molds

Differences between Casting and Molds

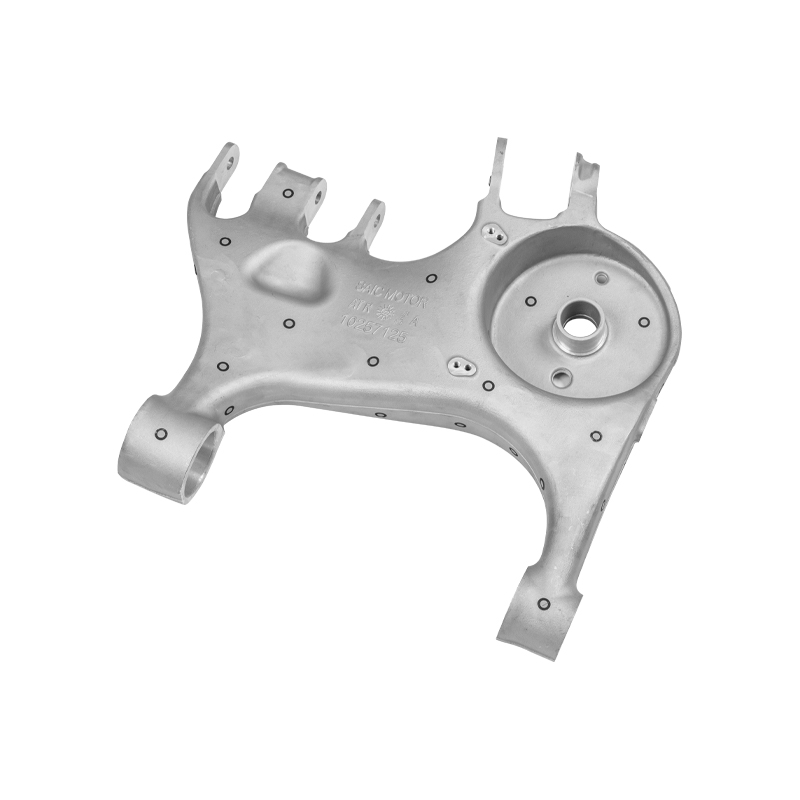

Casting: refers to the process of pouring molten metal or other materials into a mold, allowing it to cool, solidify, and form.

Mold: The tool used for casting. It determines the shape, structure, and surface quality of the final product.

Common Mold Types

Sand Mold: The most traditional and common, low-cost, suitable for large parts but with limited precision.

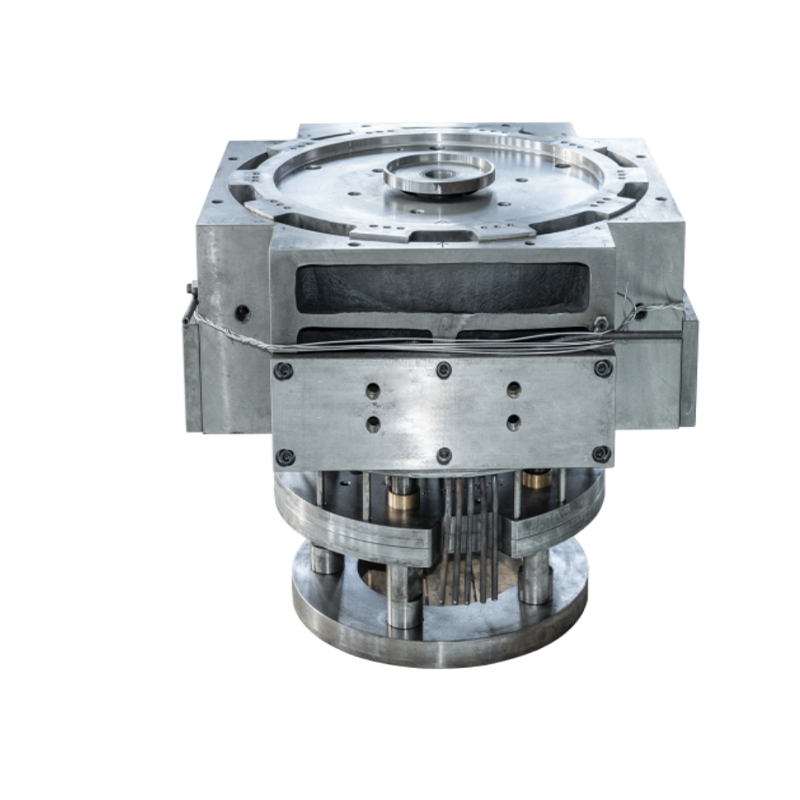

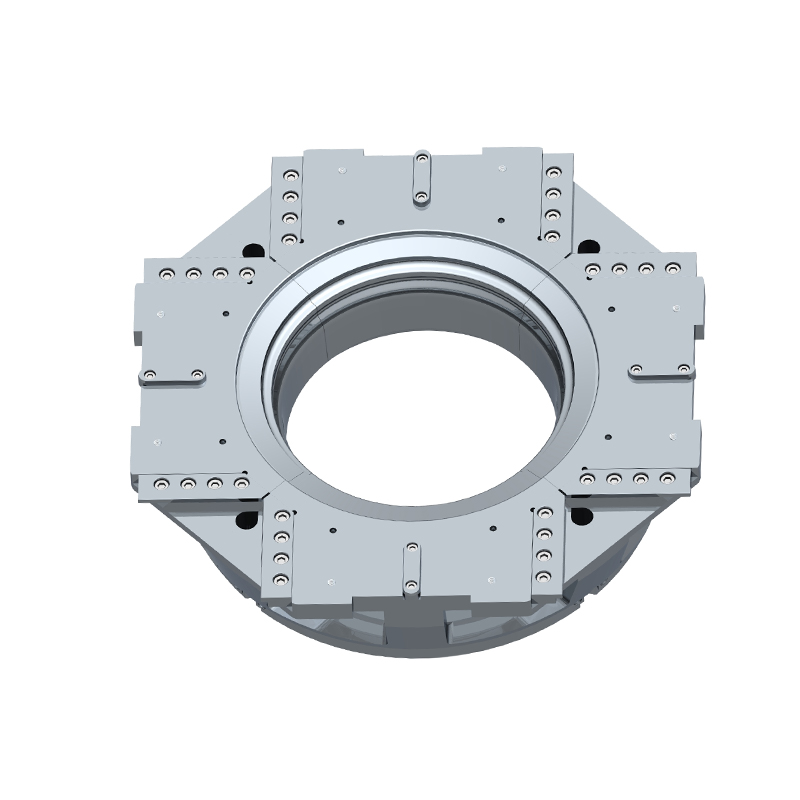

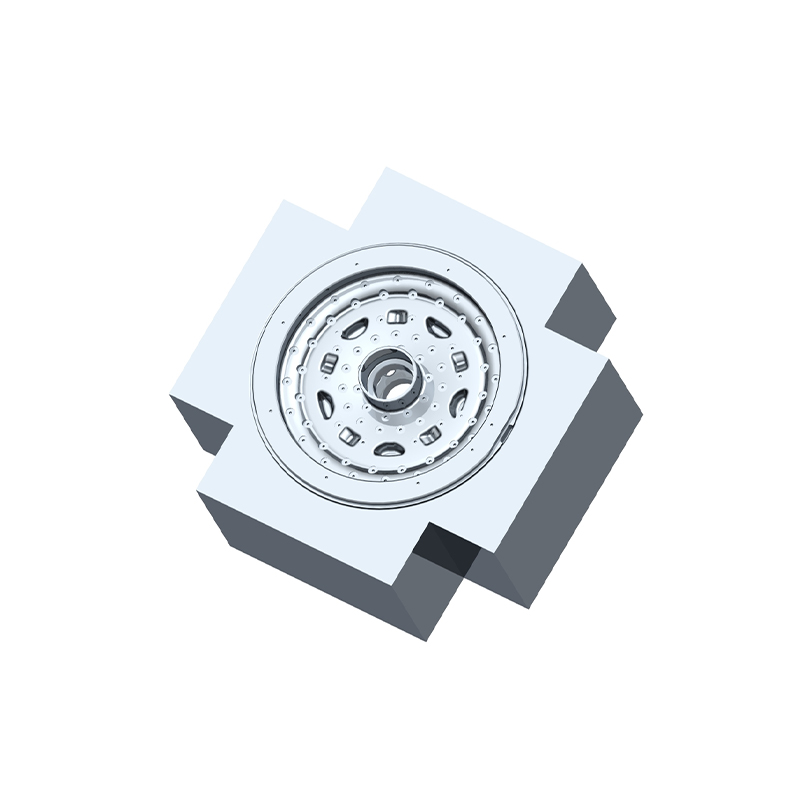

Permanent Mold: Typically made of metal, reusable, and suitable for mass production.

Ceramic Mold: High-temperature resistant and suitable for precision parts.

Plaster Mold: Suitable for complex structures, but with low strength and a short lifespan.

3D Printing Mold: Utilizes additive manufacturing for rapid prototyping and is suitable for prototyping and small-batch production.

Applications

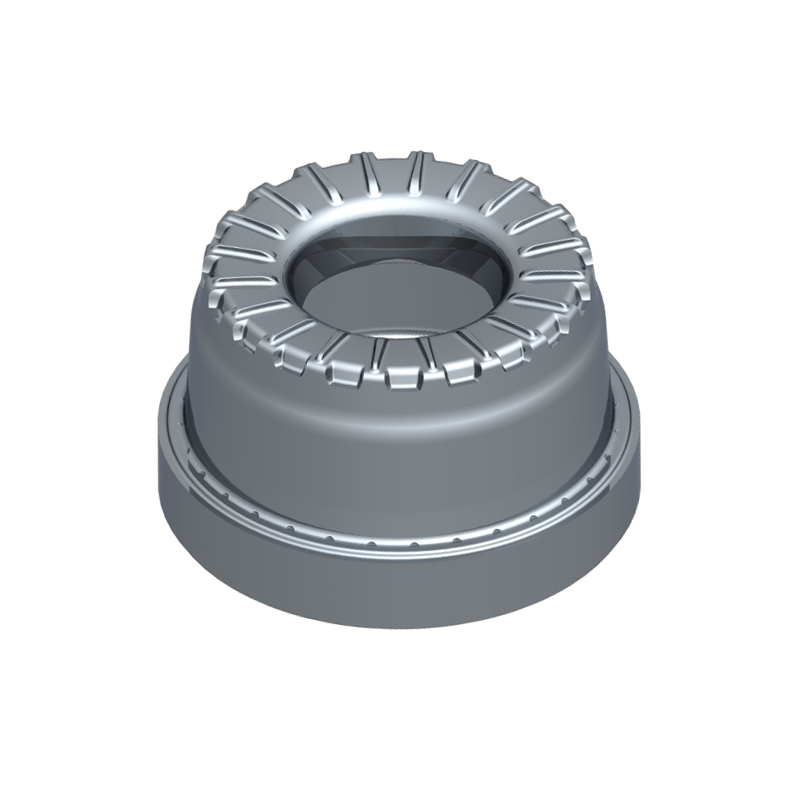

Industrial: Engine parts, aircraft turbine blades.

Consumer Products: Mobile phone cases, metal accessories.

Crafts: Sculptures, jewelry.

2. Design Phase

Design is the first step that determines the success or failure of a casting mold.

Pre-Design Considerations

Product Geometry: The more complex the product, the more complex the mold structure.

Dimensions and Tolerances: The mold must allow for shrinkage to compensate for deformation after cooling.

Material Properties: Different metals have different flow properties and shrinkage rates.

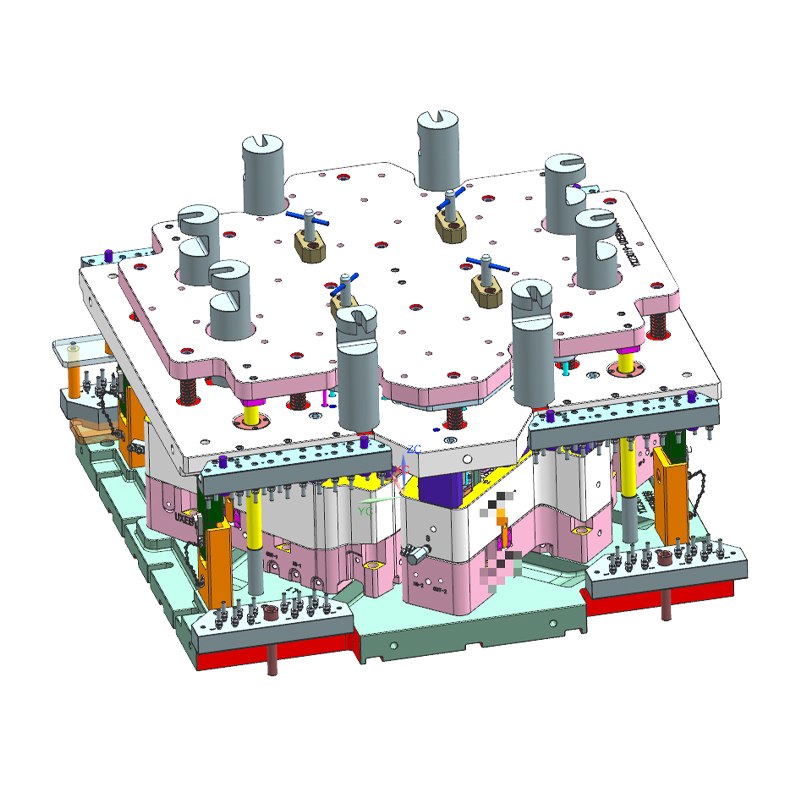

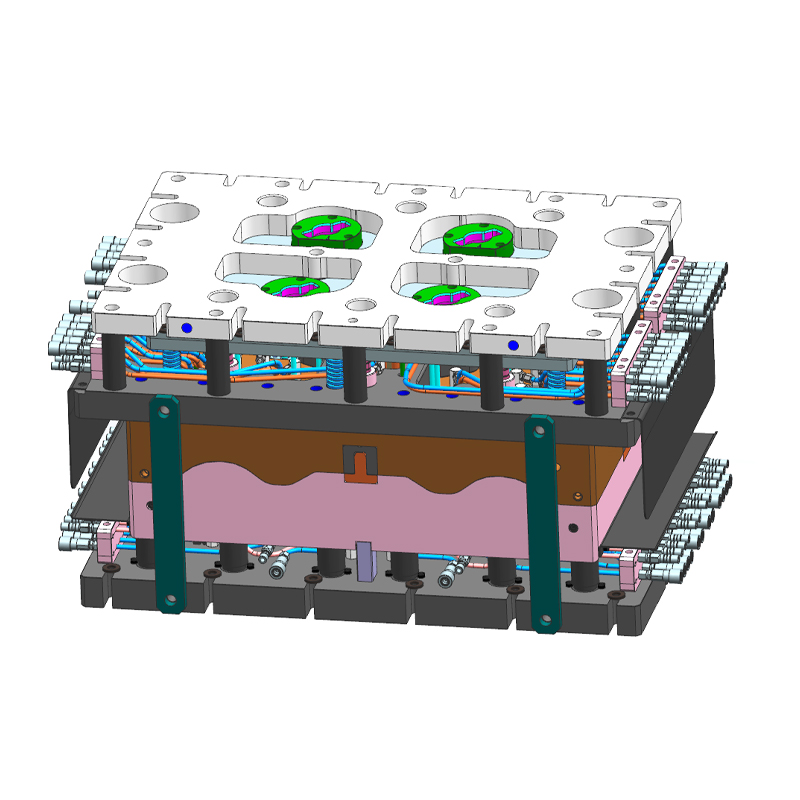

Mold Design Software

CAD (Computer-Aided Design): Creates a 3D mold model.

CAM (Computer-Aided Manufacturing): Generates machining paths.

CAE (Computer-Aided Engineering): Simulates metal flow and solidification processes to predict defects in advance.

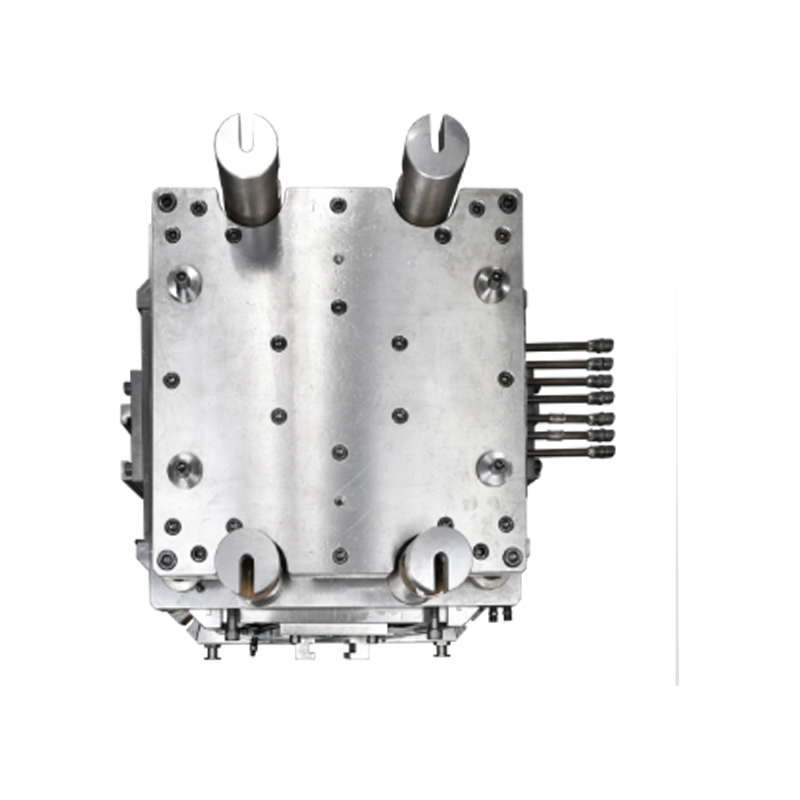

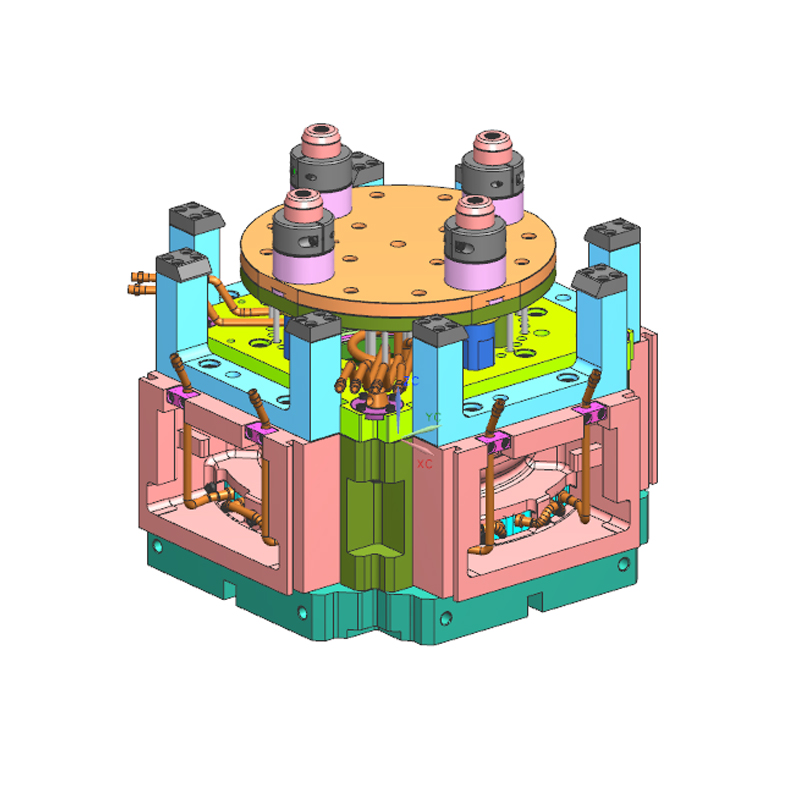

Gate, Riser, and Cooling System Design

Gating System: Ensures smooth filling of the molten metal and avoids turbulence.

Risers: Provide shrinkage compensation for the casting and reduce shrinkage defects.

Cooling System: Controls the solidification rate and prevents deformation.

Common Design Errors:

Improper Gate Position → Increased Porosity

Uneven Cooling → Deformation and Cracks

Insufficient Model Scaling → Dimensional Errors

3. Material Selection

Mold Material Comparison

Sand: Inexpensive, but has a rough surface. Metal (steel, cast iron): Durable and suitable for high production volumes.

Gypsum: Low cost, high detail reproduction, but poor heat resistance.

Ceramic: High temperature resistance, high precision, suitable for high-end parts.

Resin/Polymer: Suitable for rapid prototyping.

Choose based on casting material:

Aluminum alloy → Metal mold or sand mold

Steel → Ceramic mold

Copper, brass → Plaster mold

Cost vs. durability trade-off:

Small batches → Disposable sand molds or plaster molds are possible

Large batches → Permanent metal molds are recommended

4. Manufacturing Process

Traditional Methods:

Sand mold making: The pattern is pressed into sand and a binder is added to form the mold cavity.

Metal mold fabrication: Molds are created through forging, milling, and turning.

Modern Methods:

CNC machining: CNC machines can produce mold parts with high precision.

3D printing molds: Rapidly create complex mold cavities, especially suitable for trial production.

Surface treatment: Coatings (such as graphite and aluminum oxide) prevent metal sticking.

Heat treatment improves mold hardness and wear resistance.

5. Molding and Pouring

Melting and Pouring

Control the temperature and composition of the molten metal to avoid inclusions.

Maintain a steady pouring process to avoid turbulence and porosity.

Temperature Control

Excessively high → Reduce mold life and increase porosity.

Excessively low → Poor metal fluidity and insufficient filling.

Cooling and Solidification

Uniform cooling reduces internal stresses.

Directional solidification helps achieve a dense structure.

6. Demolding and Post-Processing

Demolding

For sand molds, directly break the mold to remove the casting.

For metal molds, use a mechanical ejector or air pressure.

Casting Cleaning

Remove the gate and riser.

Grinding and sandblasting improve surface finish.

Heat treatment improves mechanical properties.

Inspection and Quality Control

X-ray inspection: Detect internal porosity or shrinkage.

Ultrasonic inspection: Check for cracks.

Coordinate measurement: Verify dimensional accuracy.

7. Common Problems and Solutions

Shrinkage: Inadequate riser design → Increase the riser or switch to directional solidification.

Blowout: Excessive pouring speed and poor venting → Optimize the pouring system.

Cracks: Uneven cooling → Improve the cooling system or preheat the mold.

Short mold life: Severe mold wear → Surface hardening or switch to heat-resistant steel molds.

8. Future Trends in Casting Molds

Smart molds

Built-in sensors monitor temperature and pressure, providing real-time feedback on casting status.

Green Casting

Use recyclable mold materials to reduce sand waste.

Low-energy melting and non-toxic binders.

Digitalization and 3D Printing

Digital twin technology simulates the entire process, reducing trial and error costs.

Metal 3D printing directly creates molds or castings, shortening development cycles.

English

English 中文简体

中文简体