We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

The Ultimate Guide to Structural Parts Casting Molds: Design, Materials, and Applications

1. Introduction to Structural Parts Casting Molds

1.1 What are Structural Parts?

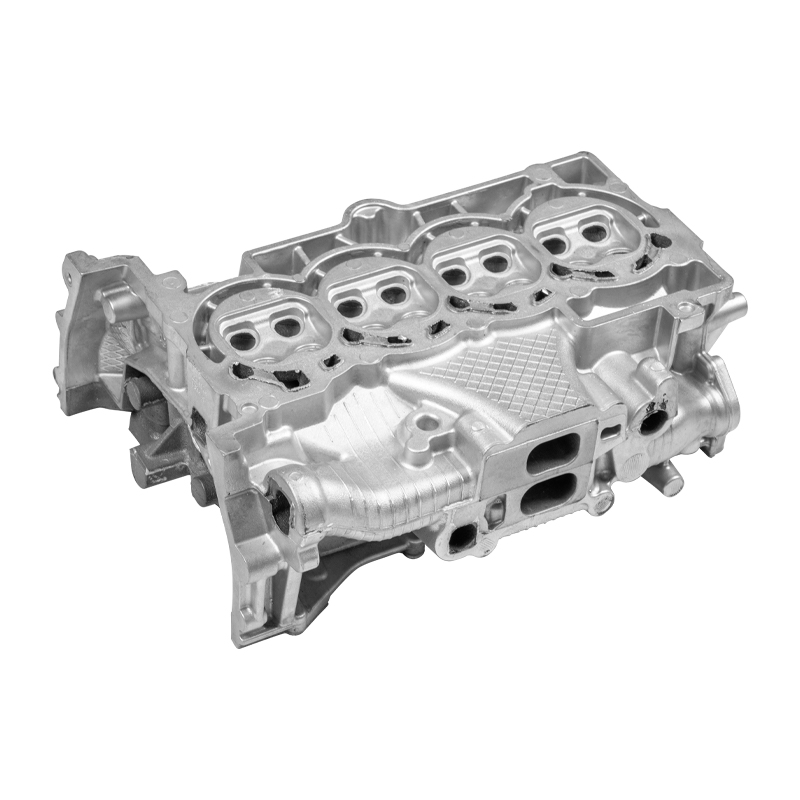

Structural parts are components designed to bear loads and provide support within a larger system or structure. They are critical for the integrity and functionality of the final product. Examples include engine blocks in cars, airframe components in aircraft, and support brackets in buildings. These parts require high strength, durability, and precise dimensions to perform their function effectively.

1.2 The Role of Casting Molds in Manufacturing

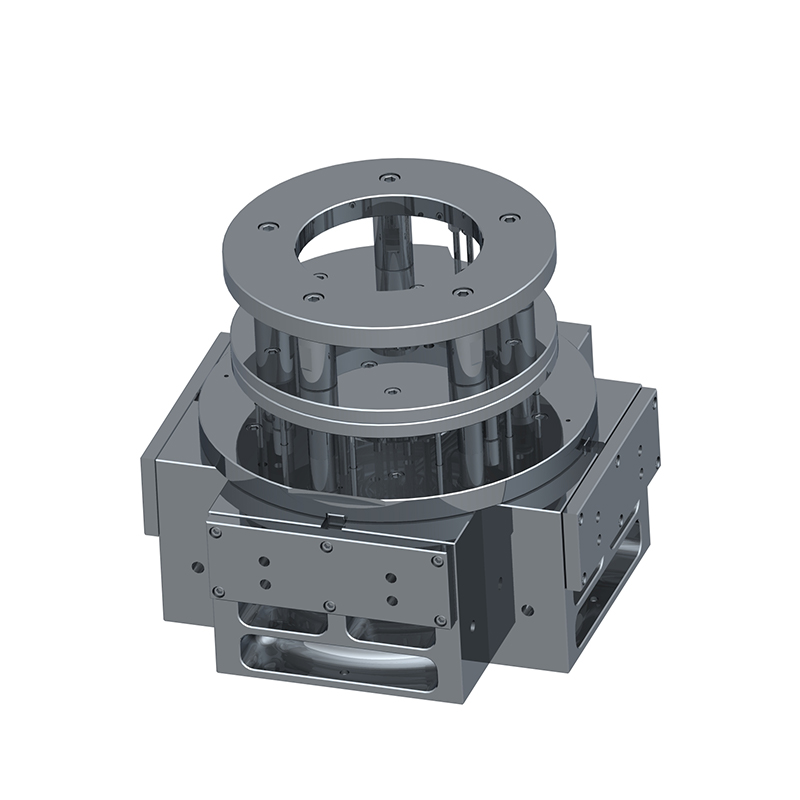

Casting molds are the core tools used to shape molten material into a desired form. They are essentially hollow forms that are filled with a liquid substance, which then solidifies to create the part. The accuracy and quality of the mold directly influence the final product's dimensional accuracy, surface finish, and mechanical properties. The use of molds allows for the efficient and repeatable production of complex shapes that would be difficult or expensive to create with other methods.

1.3 Overview of Different Casting Processes

A variety of casting processes exist, each suited for different materials, part complexities, and production volumes. Common methods include injection molding, die casting, sand casting, and investment casting. The choice of process depends on factors such as the material (metal, plastic), the size and complexity of the part, and the required precision.

2. Understanding Casting Processes

2.1 Injection Molding

Injection molding is primarily used for plastics and polymers. The process involves heating plastic pellets until they melt and then injecting the molten material at high pressure into a mold cavity. The mold is then cooled, and the solid part is ejected. This method is known for its high production speed, excellent dimensional accuracy, and ability to produce complex shapes. It's widely used for automotive parts like dashboards and bumpers.

2.2 Die Casting

Die casting is a metal casting process that forces molten metal under high pressure into a steel mold, called a die. It's especially effective for high-volume production of parts from non-ferrous metals like aluminum, zinc, and magnesium. Die-cast parts are known for their excellent surface finish and dimensional accuracy, making them ideal for engine blocks and transmission housings.

2.3 Sand Casting

Sand casting uses a mold made from sand. A pattern of the desired part is pressed into the sand to create the mold cavity. Molten metal is then poured into the cavity. This process is versatile and cost-effective for producing large, heavy, and complex parts from various metals, including iron and steel. However, it typically results in a rougher surface finish and lower dimensional accuracy compared to die casting.

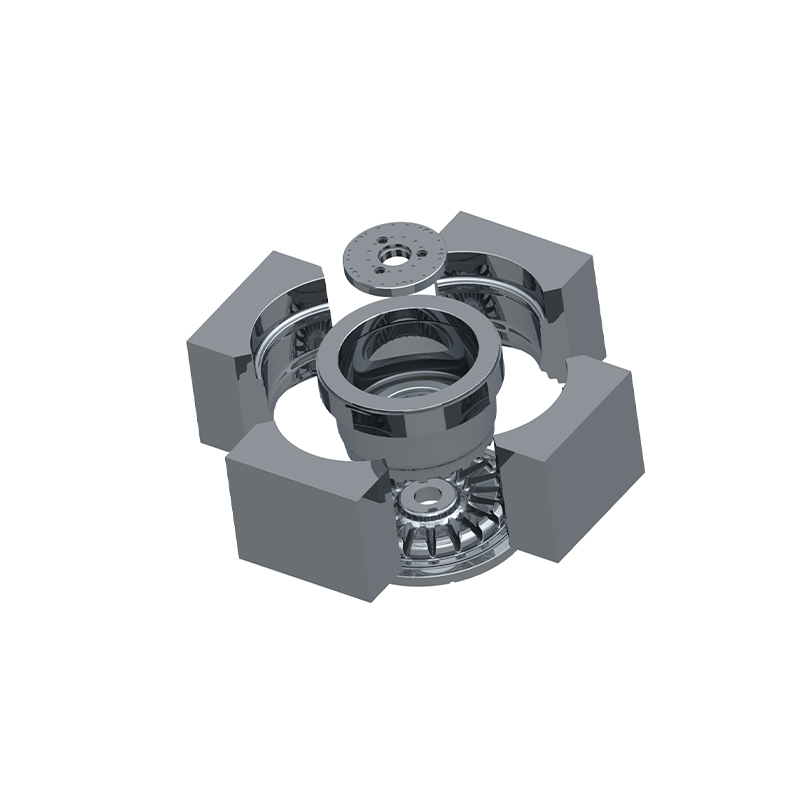

2.4 Investment Casting

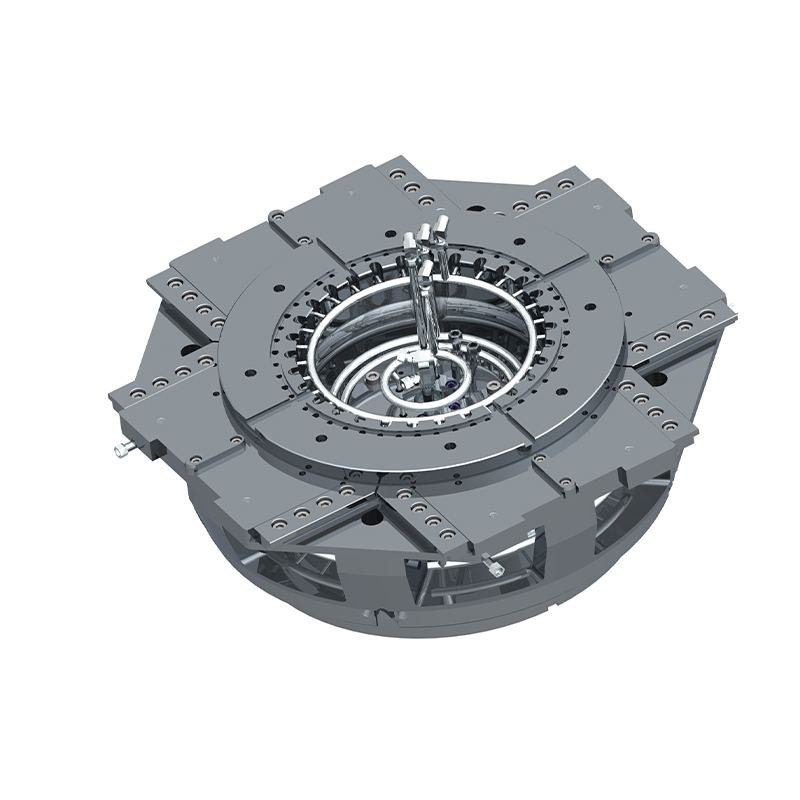

Also known as lost-wax casting, this process uses a wax pattern coated with a ceramic slurry to create a mold. After the slurry hardens, the wax is melted away, leaving a precise mold cavity. Molten metal is then poured into the mold. Investment casting is highly valued for its ability to produce parts with exceptional surface finish and intricate details, making it a preferred method for aerospace components and medical implants.

2.5 Other Casting Methods

Other notable casting methods include gravity casting, which uses gravity to fill the mold, and centrifugal casting, which uses rotational forces. These methods are chosen for specific applications, such as producing hollow cylindrical parts or components with particular material properties.

3. Key Considerations in Mold Design

3.1 Material Selection for Molds

The mold material is chosen based on the casting process and the material being cast. Steel is a common choice for die casting and injection molding due to its durability and resistance to high temperatures and pressures. Aluminum molds are used for lower-volume production or plastic injection molding because they are easier to machine and have excellent heat transfer properties.

3.2 Mold Design Principles

Effective mold design is crucial for part quality and production efficiency. Key principles include:

-

Gating systems: These are channels that guide the molten material into the mold cavity. A well-designed gating system ensures uniform flow and complete filling of the mold.

-

Venting: Vents allow air and gases to escape from the mold cavity, preventing defects like porosity.

-

Cooling channels: Integrated cooling channels regulate the temperature of the mold, ensuring the material solidifies evenly and quickly, which reduces cycle time and prevents warping.

3.3 Simulation and Optimization

Modern mold design heavily relies on Computer-Aided Engineering (CAE) software. These tools allow engineers to simulate the casting process, predicting how molten material will flow and solidify. This helps in optimizing the design before physical production, reducing costs and preventing potential defects.

4. Materials Used in Structural Part Casting

4.1 Metals and Alloys

Metals and alloys are the primary materials for structural parts due to their strength and durability. Common choices include:

-

Aluminum: Lightweight, corrosion-resistant, and strong, ideal for automotive and aerospace components.

-

Steel: Known for its high strength and toughness, used in heavy machinery and construction.

-

Magnesium: Extremely light, used when weight reduction is critical, such as in aerospace applications.

-

Titanium: High strength-to-weight ratio and corrosion resistance, essential for high-performance aerospace parts.

4.2 Plastics and Polymers

Plastics are used when a part needs to be lightweight or non-conductive. Thermoplastics (like polypropylene) can be repeatedly melted and reshaped, while thermosets (like epoxy resins) undergo an irreversible chemical change when heated and are used for more rigid, heat-resistant parts.

5. Common Casting Defects and Prevention

5.1 Types of Casting Defects

Common defects include:

-

Porosity: Small voids or bubbles within the part caused by trapped gases.

-

Shrinkage: Voids or depressions on the surface or inside the part due to uneven cooling and solidification.

-

Cracks: Fractures in the part caused by stresses during cooling.

-

Inclusions: Foreign particles or impurities trapped in the cast part.

5.2 Causes of Defects

Defects can be caused by various factors, including improper mold design, incorrect material temperatures, inadequate venting, or poor material quality.

5.3 Prevention Techniques

Prevention involves careful mold design with proper gating and venting, precise control of material temperature and pressure, and the use of simulation software to identify and correct potential issues before they occur.

6. Mold Maintenance and Longevity

6.1 Regular Cleaning and Inspection

Regular cleaning removes residue and contaminants that can affect part quality. Inspection helps identify wear and tear, cracks, or damage to the mold surface that could lead to defects.

6.2 Lubrication and Corrosion Prevention

Applying lubricants and anti-corrosion coatings to the mold surface is crucial for smooth operation and extending the mold's lifespan.

6.3 Repair and Refurbishment

Worn or damaged molds can often be repaired through welding, machining, or applying new coatings, which is more cost-effective than creating a new mold.

7. Quality Control in Structural Part Casting

7.1 Inspection Methods

Quality control ensures the final part meets specifications. Methods include visual inspection for surface defects and Non-Destructive Testing (NDT) like X-ray inspection to detect internal flaws without damaging the part.

7.2 Dimensional Accuracy and Tolerances

Parts are measured using tools like calipers and coordinate-measuring machines (CMMs) to ensure they fall within specified dimensional tolerances.

8. Applications of Structural Parts Casting Molds

8.1 Automotive Industry

The automotive sector heavily relies on casting for components like engine blocks, transmission housings, and suspension parts, where strength and precision are paramount.

8.2 Aerospace Industry

Aerospace applications require lightweight, high-strength parts. Investment casting is often used for airframe components and engine parts made from titanium and other high-performance alloys.

8.3 Construction Industry

Castings are used for structural supports, connectors, and decorative elements in buildings and bridges, where durability and load-bearing capacity are essential.

9. Future Trends in Casting Mold Technology

9.1 Additive Manufacturing for Mold Making

3D printing is revolutionizing mold making by enabling the rapid production of complex mold components or patterns, reducing lead times and costs, especially for prototypes and small-batch production.

9.2 Advanced Materials and Coatings

New materials and coatings for molds are being developed to improve durability, heat resistance, and release properties, further extending mold life and enhancing part quality.

9.3 Automation and Robotics in Casting

Automation is being increasingly used to handle materials, operate machinery, and perform quality checks, leading to higher efficiency, reduced labor costs, and improved consistency in the casting process.

English

English 中文简体

中文简体