We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

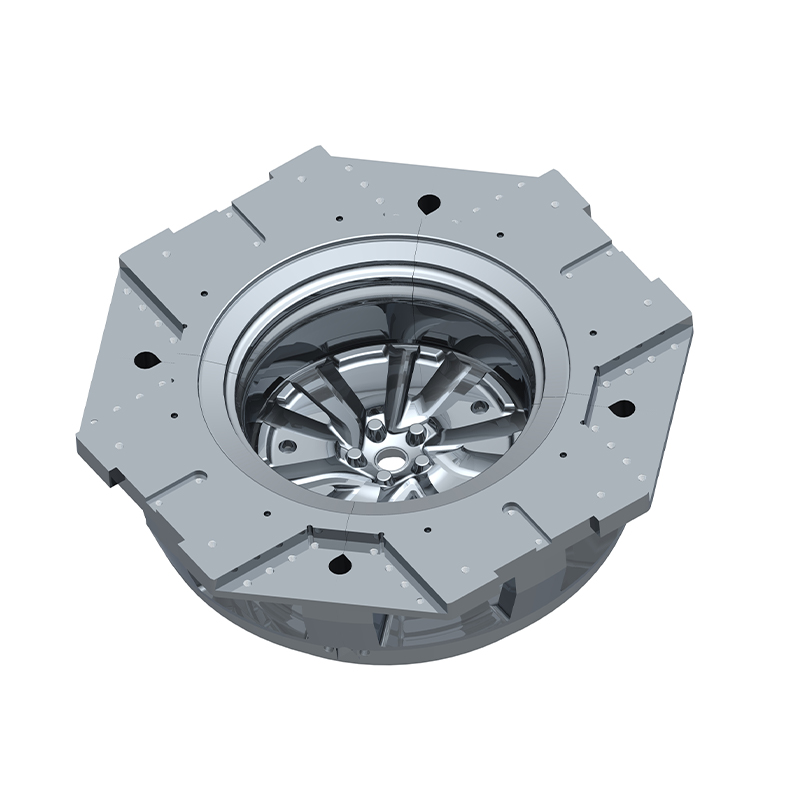

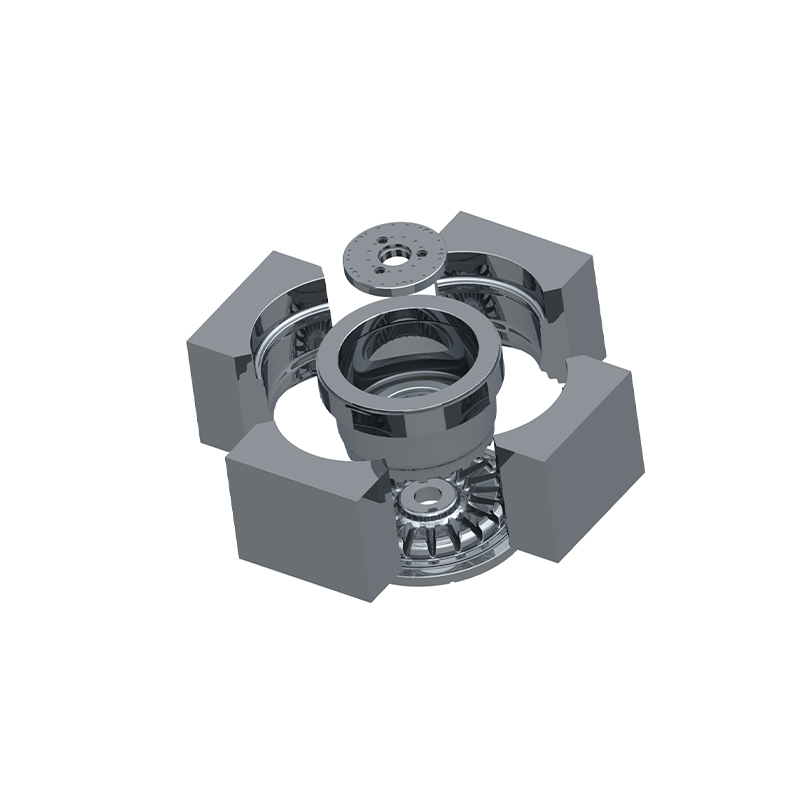

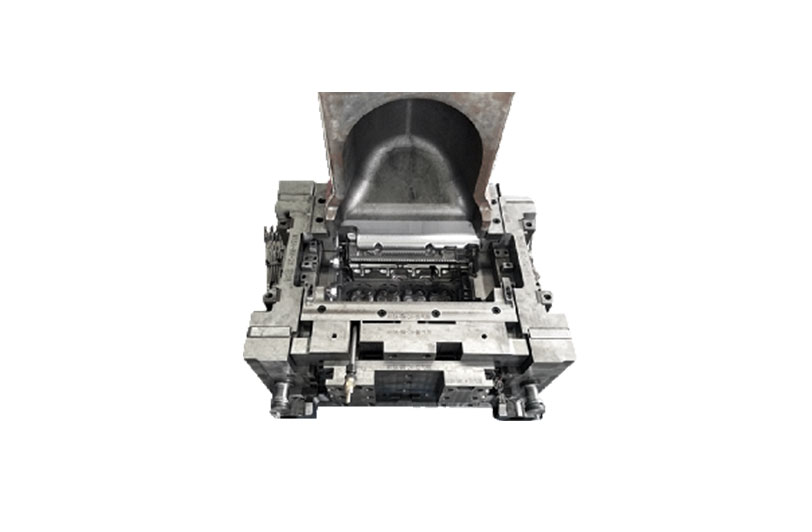

How to improve Wheel Hub production efficiency through low-pressure casting molds?

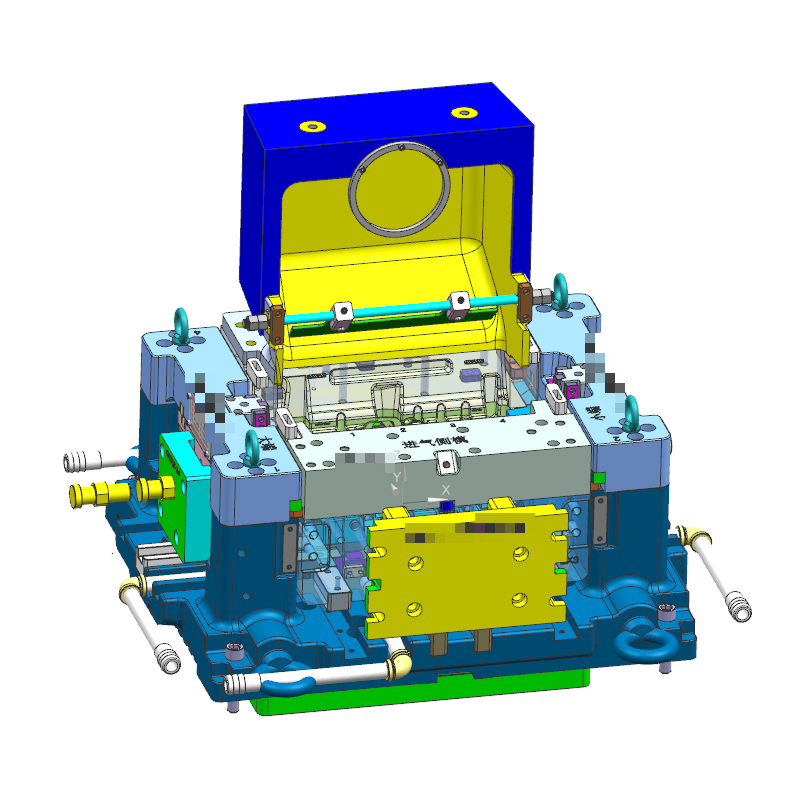

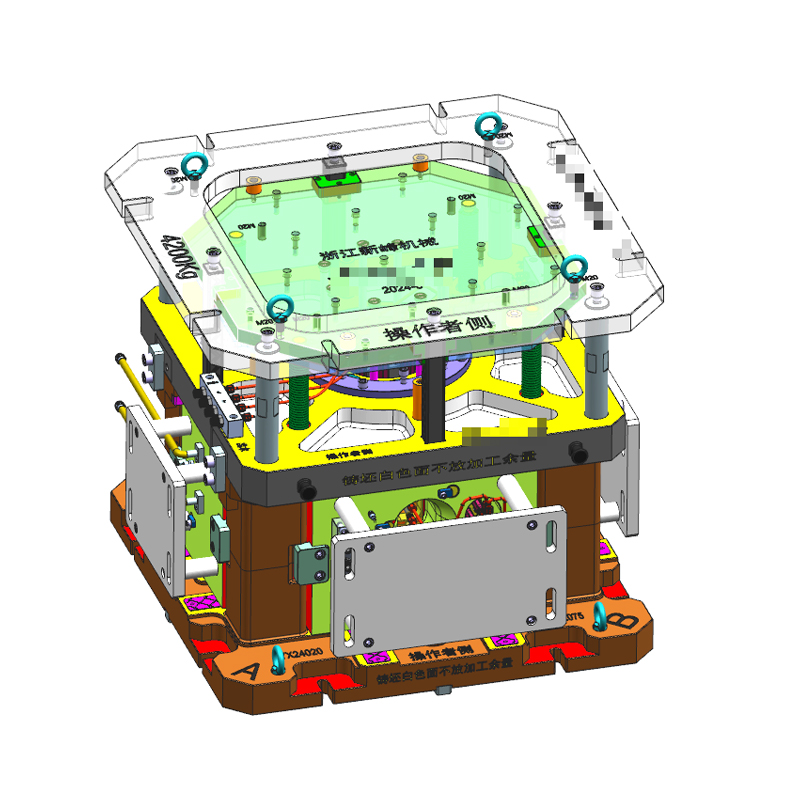

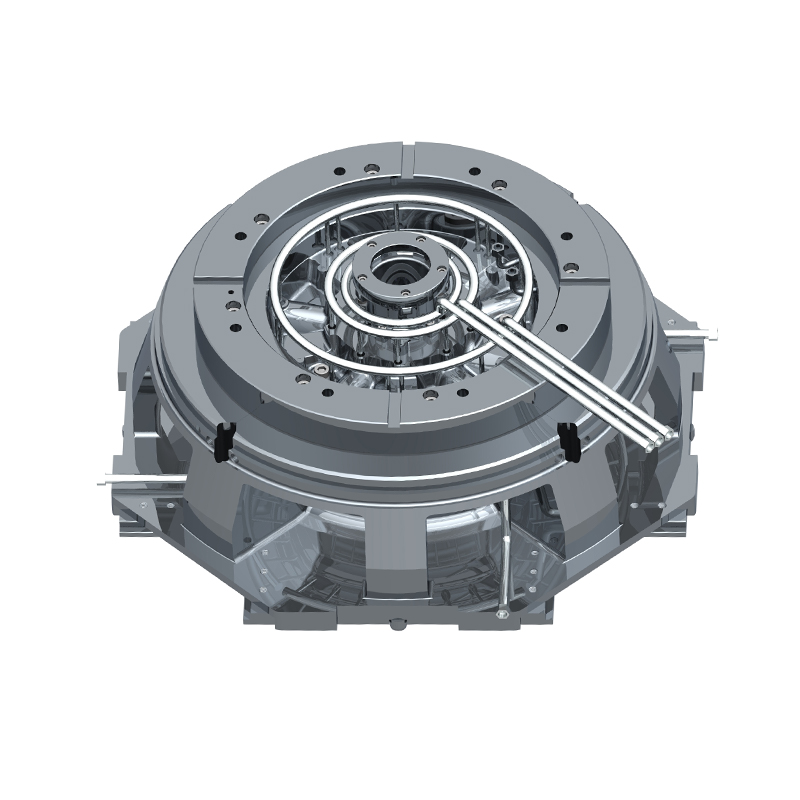

Optimizing Mold Design

Optimizing Wheel Hub Low Pressure Casting Mold design is a crucial step in improving the production efficiency of low-pressure casting for Wheel Hubs. The precision and efficiency of the mold design directly affect the filling quality, production cycle, and cost control of the casting. Optimized mold design can maximize production efficiency, reduce material waste, and minimize labor time.

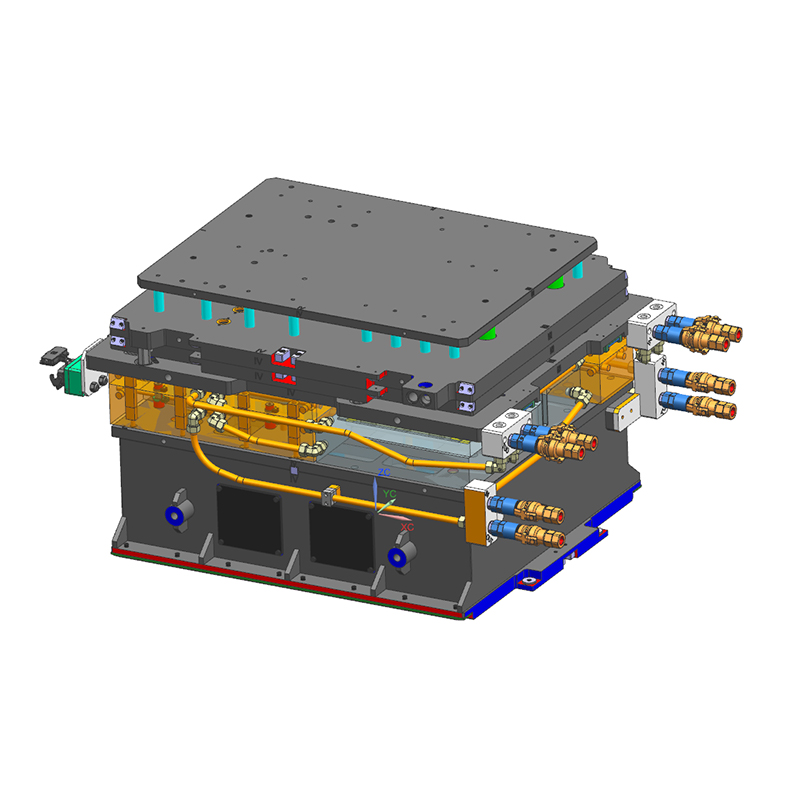

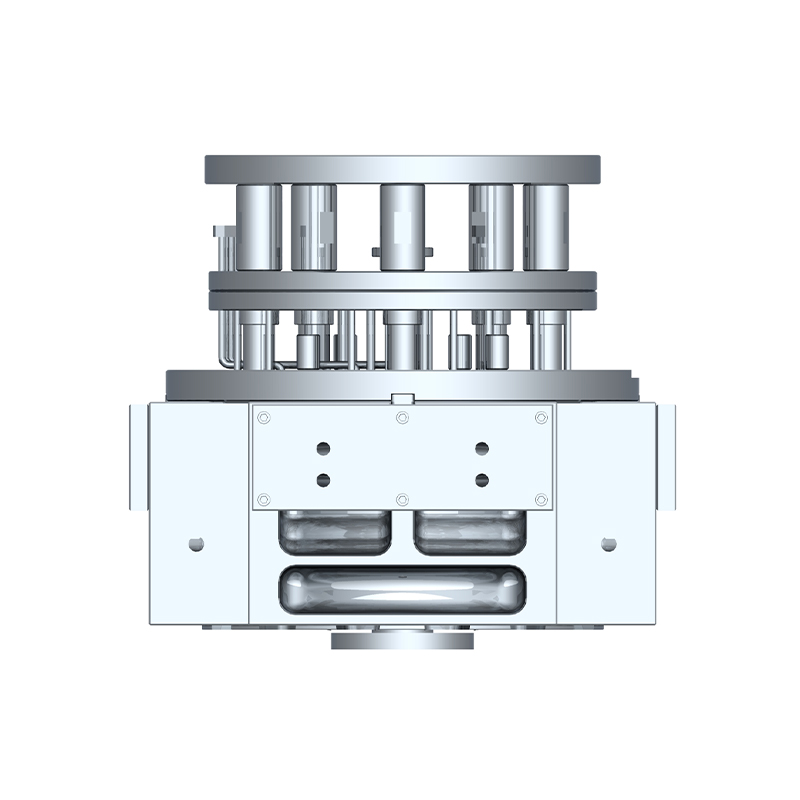

Precision Cooling Channel Design

The cooling system plays a vital role in low-pressure casting. Proper design of cooling channels not only helps in rapid solidification of the casting but also ensures the dimensional accuracy and surface finish of the castings. The layout of cooling channels should conform to fluid dynamics principles to evenly distribute the cooling medium, reducing issues of localized overheating or undercooling. By optimizing the cooling channels, cooling time can be effectively reduced, energy consumption minimized, and overall efficiency improved.

In the design of the cooling system, it is recommended to use Computational Fluid Dynamics (CFD) simulation technology to accurately model the flow of cooling media and heat transfer. By doing so, potential issues can be identified during the design phase, allowing for optimal cooling channel layouts that shorten cooling time, reduce energy consumption, and enhance overall efficiency.

Using High Thermal Conductivity Materials

The thermal conductivity of the mold material directly impacts the cooling rate of the casting. Faster cooling rates are essential for reducing production cycles. High thermal conductivity materials, such as copper alloys, aluminum alloys, and graphite, can significantly improve heat transfer between the mold and the casting, thereby reducing cooling time and increasing production efficiency.

Moreover, high thermal conductivity materials can also improve the durability of the mold, reducing the frequency of mold failure, which lowers maintenance costs and downtime. Choosing appropriate materials ensures higher production efficiency while maintaining casting quality.

Improving Mold Runner Design

The optimization of the mold runner design is another key factor in improving production efficiency. The runner design not only affects the flowability of the molten metal but also influences the filling speed and quality of the casting. Poor runner design can lead to issues such as air pockets, inclusions, or incomplete filling of the mold, which can impact both the quality and efficiency of production.

Optimizing runner design typically involves adjustments to factors like runner diameter, length, bending angles, and the locations of entry and exit points. During the design process, simulation analysis should be performed to ensure smooth flow of the molten metal through the runner, avoiding accumulation of gas and impurities, and ensuring the accuracy and strength of the casting.

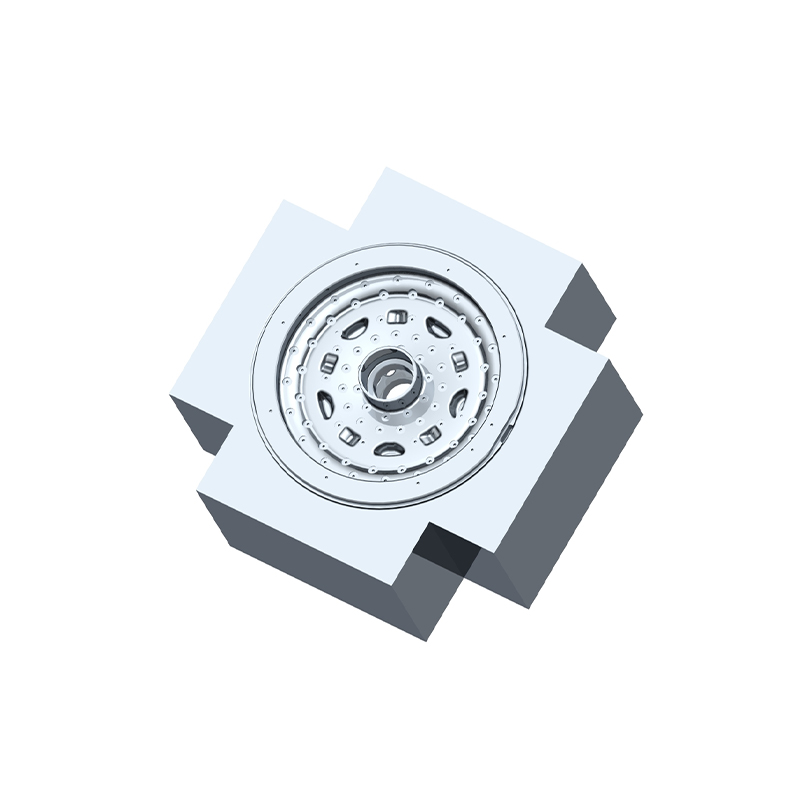

Precise Control of Casting Parameters

Precise control of casting parameters is another crucial way to improve low-pressure casting production efficiency. By accurately controlling key parameters such as pressure, temperature, and flow rate, casting defects can be minimized, production stability and consistency can be ensured, and overall production efficiency can be improved.

Control of Low-Pressure Casting Pressure

Pressure control is critical in low-pressure casting. Insufficient pressure may result in incomplete filling of the mold or casting defects such as air pockets or voids. Conversely, excessive pressure can damage the mold or cause metal overflow, resulting in material waste. To improve production efficiency, pressure during the casting process must be strictly controlled.

The best method for controlling pressure is through automated systems that monitor pressure fluctuations in real-time and adjust it based on the casting process needs. Using CNC technology, pressure can be adjusted during the casting process to ensure smooth flow and filling of the molten metal, preventing defects caused by pressure instability.

Temperature Control

The control of casting temperature directly affects the quality and efficiency of the casting. Both excessively high and low temperatures can impair the fluidity of the molten metal and result in cracks, air pockets, or other issues. To ensure high-quality castings and production stability, the temperature during the casting process must be strictly controlled.

Using high-precision temperature control systems allows for precise regulation of both the molten metal temperature and the mold temperature, avoiding defects due to temperature fluctuations. In addition to improving equipment accuracy, intelligent temperature control technologies should be considered to make temperature control more precise and efficient.

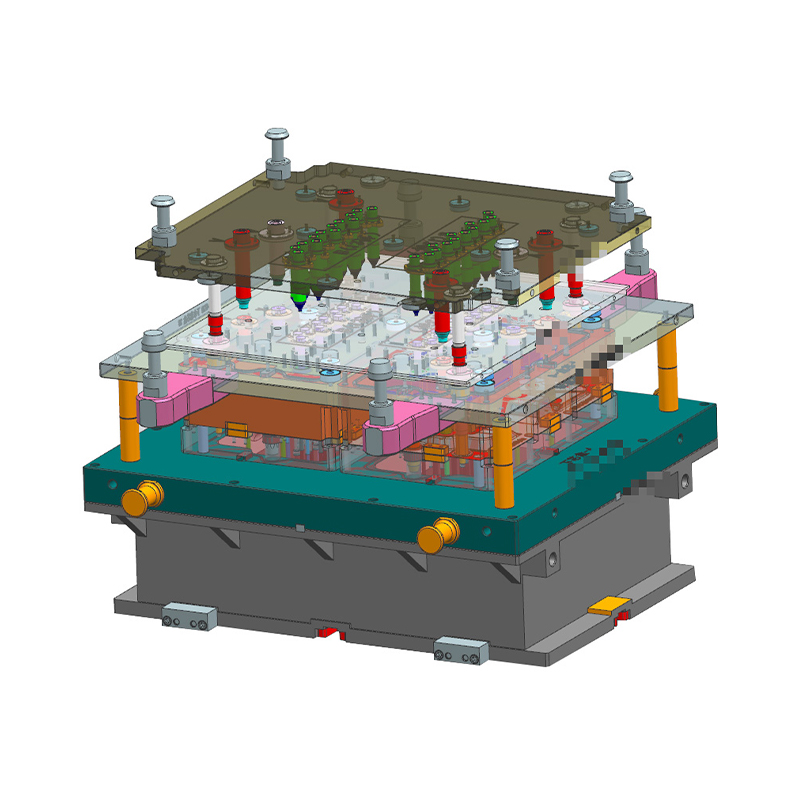

Increasing Automation Level

With the advancement of technology, automation has become a key factor in improving production efficiency in low-pressure casting. By introducing automated equipment and intelligent management, labor costs can be reduced, production efficiency can be significantly increased, and human errors can be minimized.

Automated Casting Equipment

Automated casting equipment can complete tasks such as mold injection, pressurization, and cooling in a relatively short time, thus greatly improving production efficiency. These systems are often equipped with high-speed casting machines, robotic arms, and automatic feeding systems, making the production process more efficient and stable.

Automated casting equipment can follow standard operating procedures (SOPs) to ensure the precision and consistency of each casting cycle, reducing human error. By integrating and optimizing equipment, each step of the casting process can be automated, further improving efficiency and quality.

Automated Inspection Systems

Automated inspection systems play a crucial role in low-pressure casting. By using smart sensors and image recognition technologies, these systems can monitor key quality parameters of castings in real-time, such as dimensions, weight, and surface defects. Inspection systems can identify potential issues early, allowing adjustments to be made during the casting process, thus preventing the production of defective castings.

Automated Production Lines

Establishing automated production lines can automate various steps of the casting process, including molding, cleaning, inspection, and packaging. This integrated production line not only significantly improves the production speed but also reduces human intervention, further enhancing efficiency.

Extending Mold Life

The life of the mold is directly related to production efficiency. Frequent mold failure or replacement can lead to production line downtime, impacting overall production efficiency. Therefore, extending the life of the mold not only helps to reduce production costs but also improves production stability.

Mold Coating Technology

Mold coating technology can effectively extend the life of molds. Coatings enhance the mold’s resistance to wear, corrosion, and high temperatures, reducing mold wear and thermal fatigue, and ultimately extending mold life. Common mold coatings include ceramic coatings, aluminum alloy coatings, etc.

Regular Maintenance and Inspection

Molds inevitably undergo wear and tear during use. Therefore, regular maintenance and inspection are essential. By regularly cleaning, repairing, and inspecting the molds, potential issues can be identified early, preventing mold failure from halting production. Routine maintenance and care ensure that molds remain in optimal working condition, improving production efficiency.

Optimizing Production Processes

Optimizing production processes is the foundation of improving efficiency. By refining each step of the production workflow, reducing unnecessary delays and waste, overall production efficiency can be enhanced.

Parallel Production Processes

Where possible, using parallel production processes can enable multiple tasks to be performed simultaneously, avoiding production bottlenecks. For example, multiple molds can be cast at different stations at the same time, increasing the yield per production cycle.

Reducing Mold Change Time

Mold change time has a significant impact on production efficiency. Frequent mold changes can lead to production line downtime, especially in high-volume production. Therefore, adopting quick mold-change designs can significantly reduce mold-change time between different production batches, increasing overall efficiency.

Precise Control of Process Stability

Ensuring process stability is critical to improving low-pressure casting production efficiency. A stable process allows the production line to maintain high efficiency, reduce downtime, and minimize quality issues.

Standardized Operating Procedures

By establishing strict operating procedures and standard operating procedures (SOPs), consistency can be ensured in each step of the production process, minimizing human error. Standardization helps workers improve their operational proficiency, reducing mistakes during production, thus ensuring both process stability and efficiency.

Data Monitoring and Feedback Mechanism

Real-time data monitoring and feedback mechanisms can help to track key production parameters such as mold temperature, casting pressure, and molten metal flow rates. Adjustments can be made promptly during the casting process to ensure that production remains stable, reducing defect rates and enhancing efficiency.

English

English 中文简体

中文简体