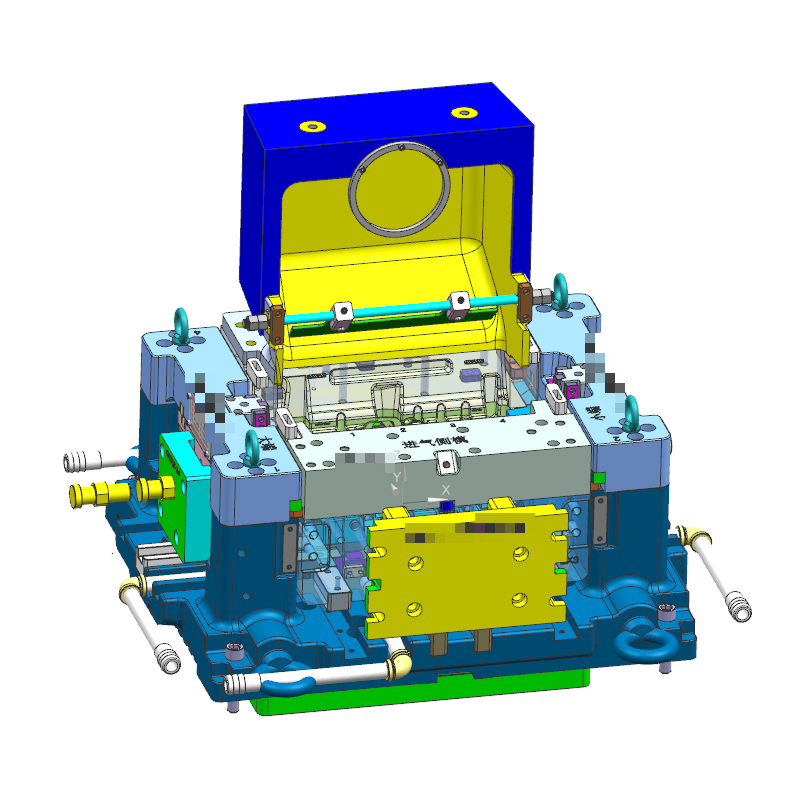

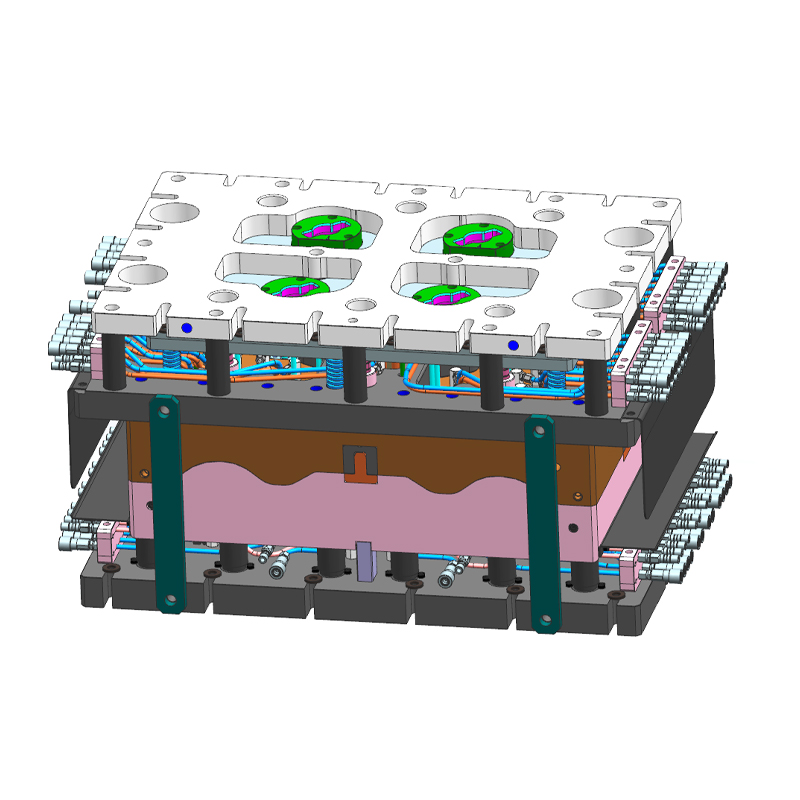

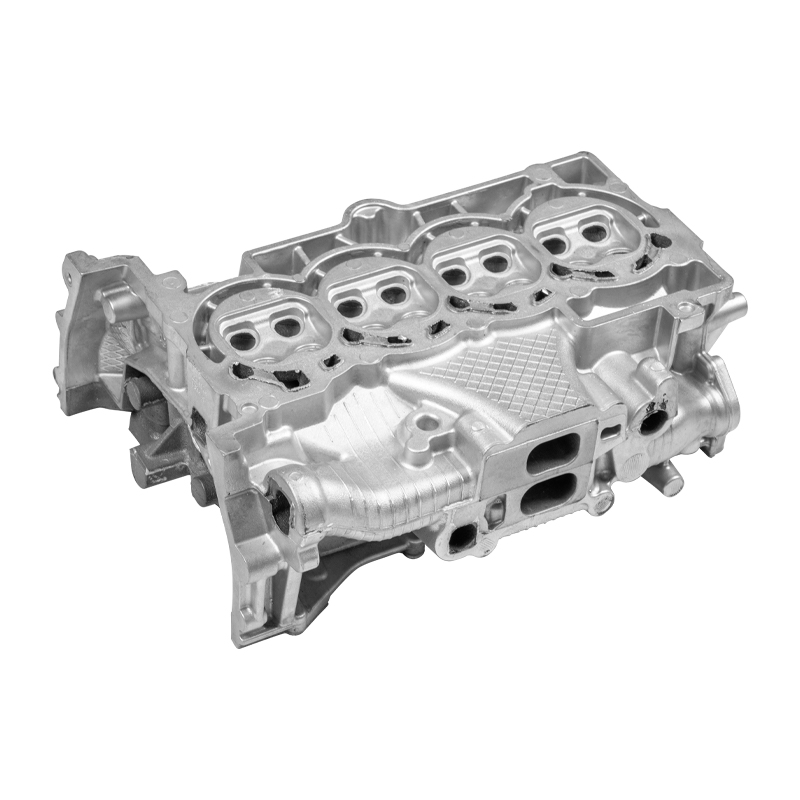

We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

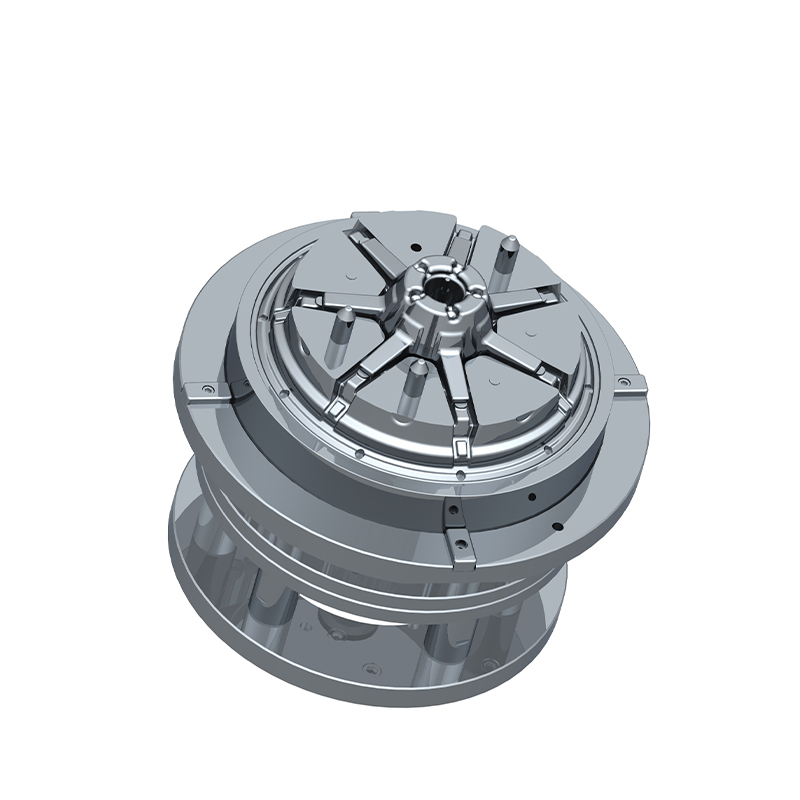

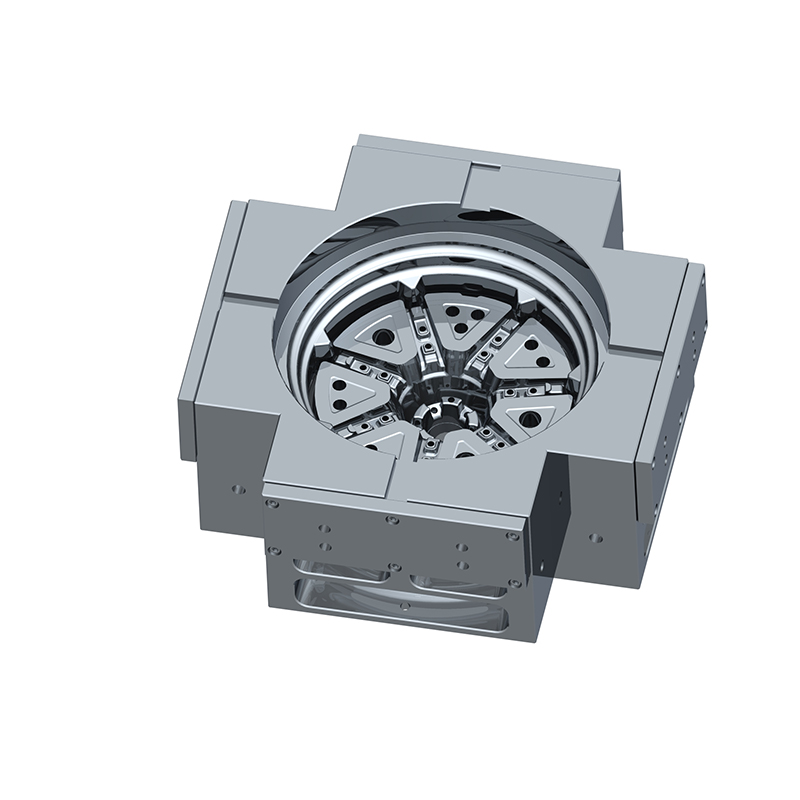

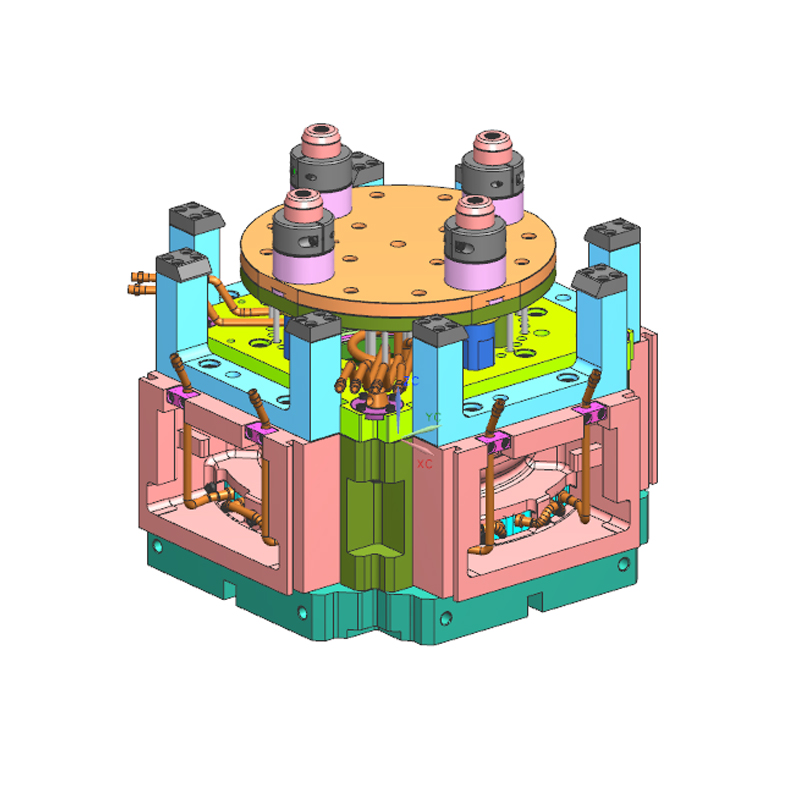

Wheel Hub Gravity Casting Mold Design: Tips for Improved Efficiency

1. Understanding Materials and Casting Requirements

Material Selection: Wheel hubs are commonly gravity-cast using aluminum alloys (such as A356) due to their low density, corrosion resistance, and ease of machining. The flowability, cooling rate, and shrinkage of the material directly affect mold design and casting quality.

Material Properties: Aluminum alloys typically have a linear shrinkage rate of about 1–1.2% and good fluidity, but are sensitive to cold shuts and shrinkage defects. The wall thickness should be uniform to avoid thin or thick areas that may cause defects.

Design Implications: The mold must compensate for metal shrinkage while ensuring proper gating, riser placement, and smooth metal flow into complex geometries without porosity or cold shuts.

2. Mold Design Considerations

a) Draft Angles

Draft Design: Vertical surfaces should have a 2–5° draft angle to facilitate demolding. Deep cavities or complex geometries may require larger draft angles to reduce mold wear and casting defects.

b) Fillets and Transitions

Fillet Design: Avoid sharp corners; a fillet radius of 3–10 mm is recommended. Fillets help reduce stress concentration, improve metal flow, and lower the risk of porosity and cold shuts.

c) Parting Line

Parting Line Location: Should be placed on less visible or low-stress surfaces. Proper parting line design allows easier gating and riser placement, and reduces post-processing requirements.

d) Core Placement

Core Usage: For internal cavities such as bearing seats, cores are required. Cores must be stable and well-positioned to avoid flash while ensuring complete metal filling.

Wheel Hub Gravity Casting Mold

3. Feeding System Design

a) Gate Design

Gate Type: Single central gates or multiple smaller gates can be used to ensure even metal filling. Gate cross-sections should be smooth and tapered (6–10°) to reduce turbulence and air entrapment.

b) Riser Placement

Riser Location: Place risers in thick sections to compensate for casting shrinkage. Riser size and number should be optimized through calculations or simulation to prevent shrinkage defects.

c) Runner Design

Runner Optimization: Avoid sharp angles and narrow passages to reduce flow resistance and oxide formation. Excessively long runners can increase the risk of cold shuts and porosity.

| Parameter | Value | Description |

|---|---|---|

| Material | A356 Aluminum Alloy | Commonly used for lightweight wheel hubs |

| Linear Shrinkage | 1–1.2% | Must be considered in mold design |

| Draft Angle | 2–5° | Facilitates demolding |

| Fillet Radius | 3–10mm | Reduces stress concentration |

4. Thermal Management

Cooling Measures

Directional Cooling: Use chills or heat sinks in areas prone to cold shuts to help metal solidify evenly and quickly.

Mold Preheating

Preheating Temperature: Aluminum molds are typically preheated to 200–250°C to delay metal solidification, ensure complete filling, and reduce porosity and shrinkage defects.

5. Gravity Casting Optimization

Casting Orientation

Mold Tilt: Tilt the mold based on wheel hub geometry so the metal naturally flows into cavities, reducing air entrapment and turbulence.

Flow Simulation

Simulation Software: Software such as MAGMA or ProCAST can predict metal flow, air entrapment, and cold shut locations, allowing optimization of gates and risers in advance.

Turbulence Control

Reducing Turbulence: Avoid sharp turns and abrupt transitions in runners to minimize oxide formation and surface defects.

6. Mold Material and Lifespan

Mold Material

Sand Molds: Low cost, suitable for small batch production.

Metal Molds: Steel or aluminum molds are suitable for high-volume production, offering better surface finish and longer life.

Mold Coatings

Coating Purpose: Applying release agents or refractory coatings improves metal flow, reduces sticking, and decreases surface defects.

7. Inspection and Maintenance

Regular Inspection

Key Areas: Regularly check gates, risers, cores, and mold cavities for wear to maintain dimensional accuracy and casting quality.

Maintenance Methods

Cleaning and Assembly: Mold design should allow easy disassembly and cleaning to extend mold life and reduce production downtime.

8. Additional Efficiency Improvement Tips

- Simplify Mold Design: Simpler structures cool faster and shorten production cycles.

- Modular Design: Enables faster replacement and maintenance.

- Standardize Risers and Gates: Improves production consistency.

- Preheat Molds: Ensures thermal stability and reduces casting defects.

- Maintain Consistent Draft Angles: Reduces stuck parts and rework, improving efficiency.

English

English 中文简体

中文简体