We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

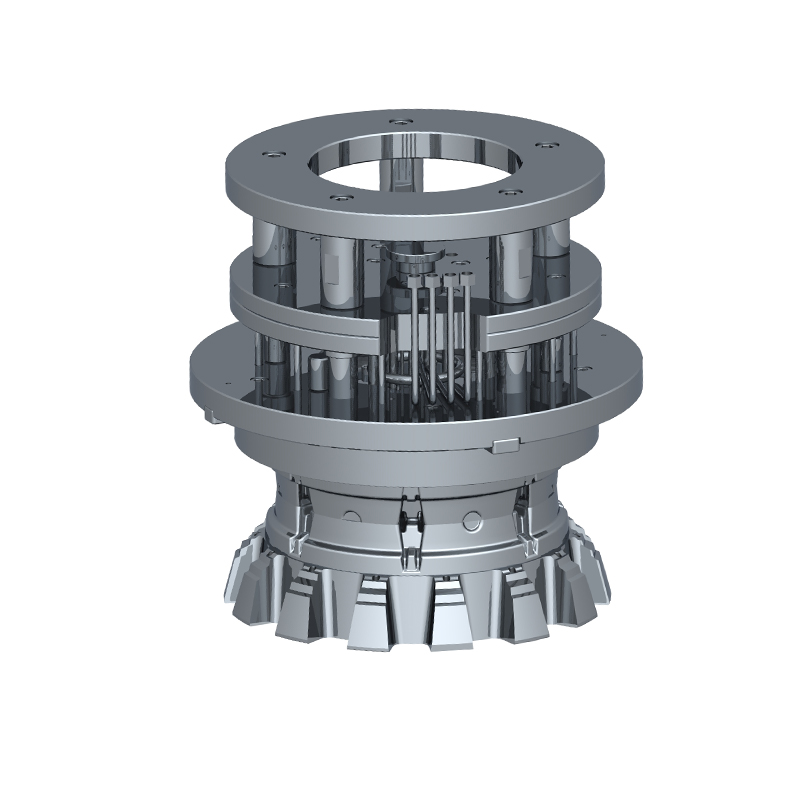

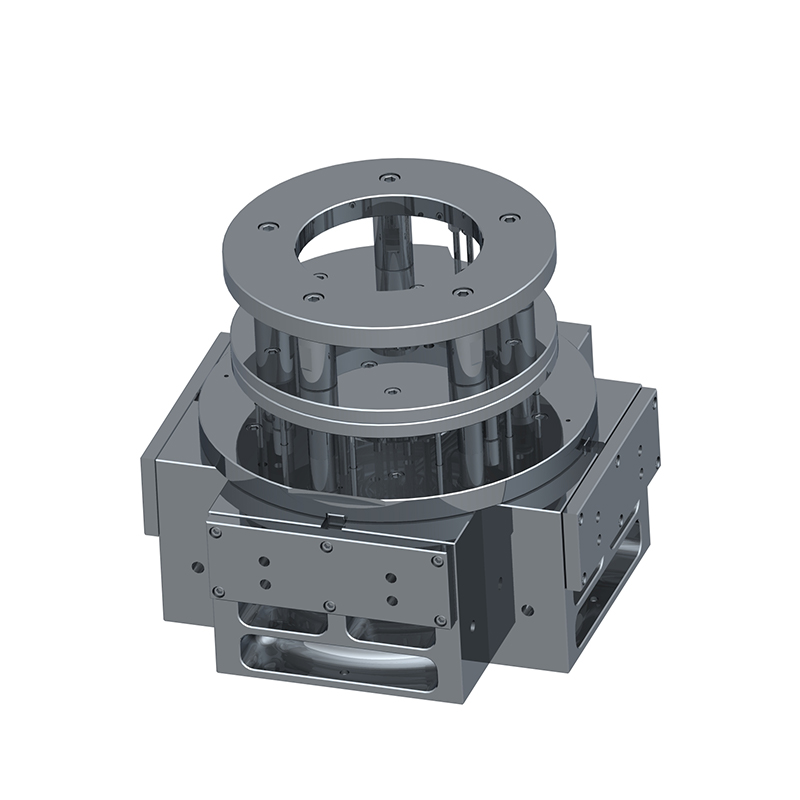

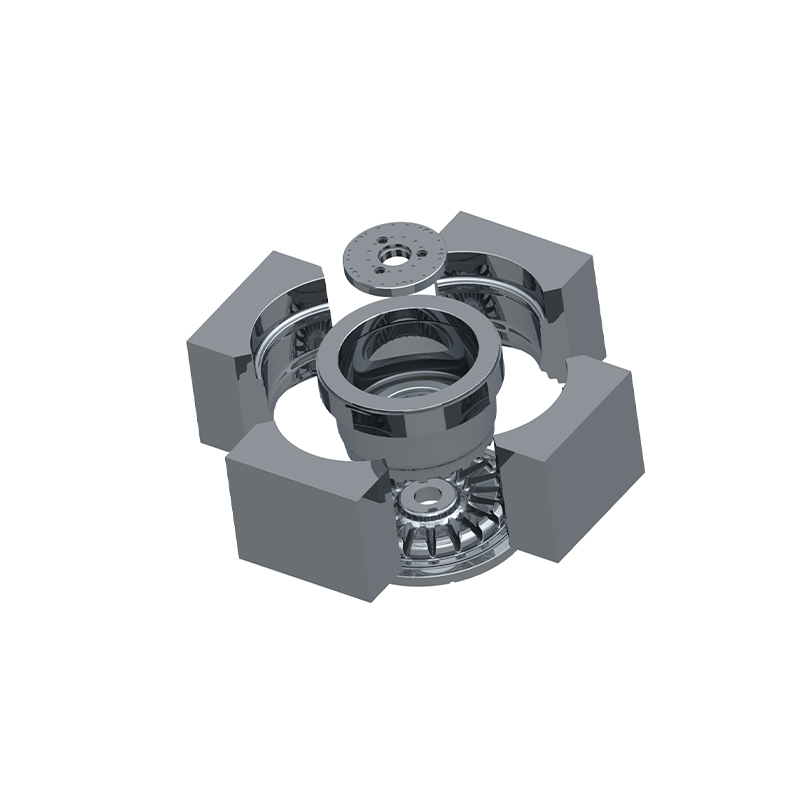

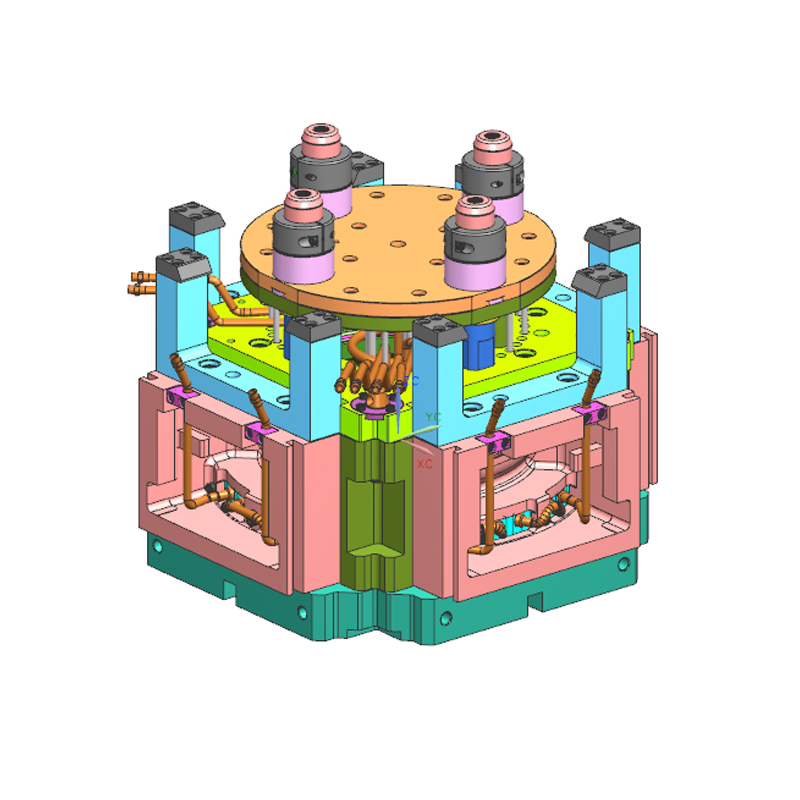

Wheel Hub Motorcycle Casting Mold vs. Forging: What’s the Difference?

In the manufacturing of motorcycle wheel hubs, casting and forging are two primary methods used. Each method has its advantages and disadvantages, and they are suited for different types of motorcycles and usage scenarios.

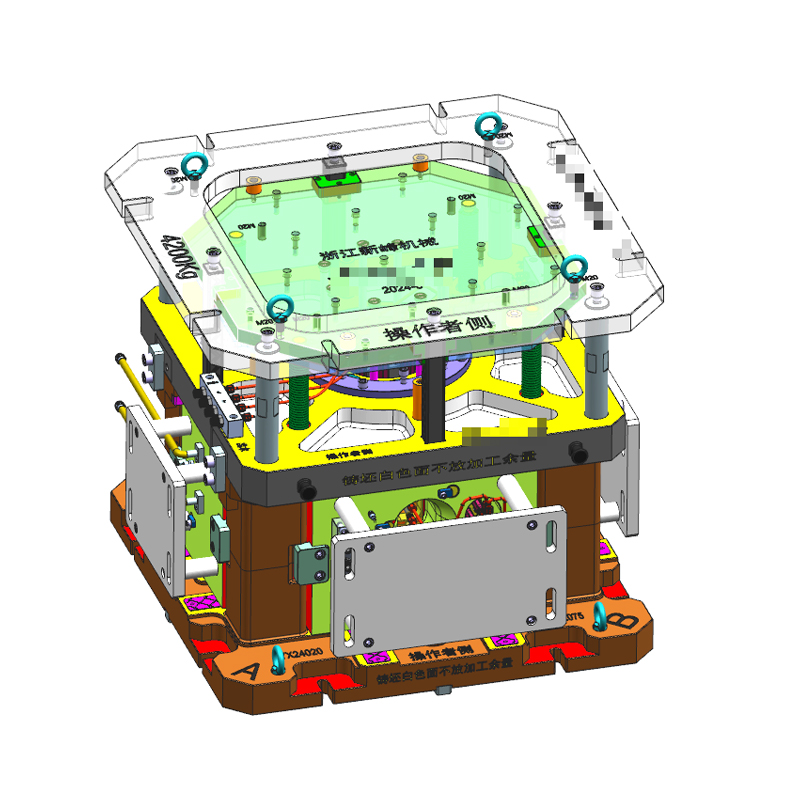

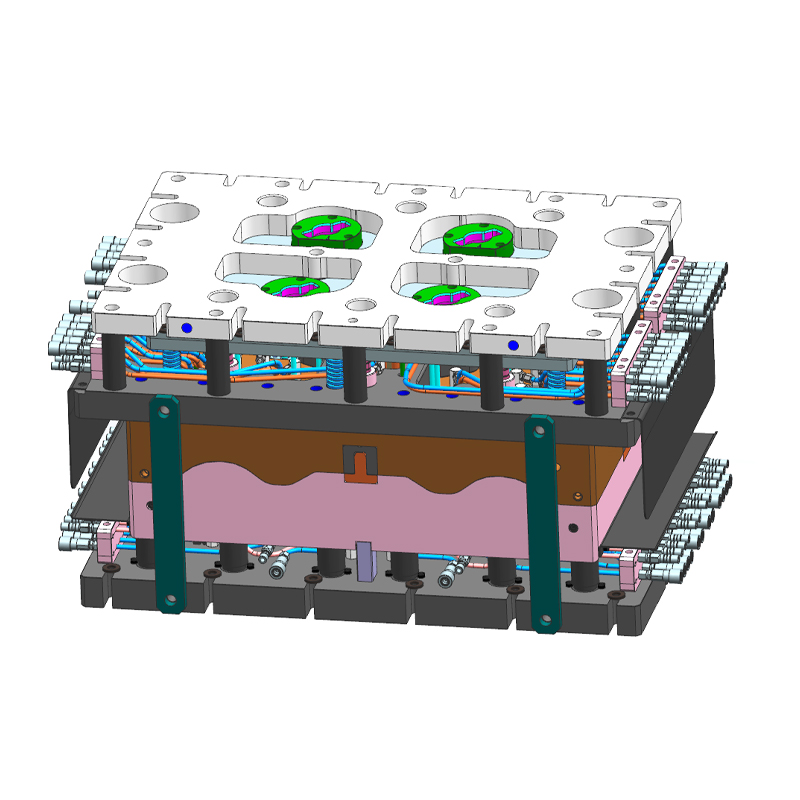

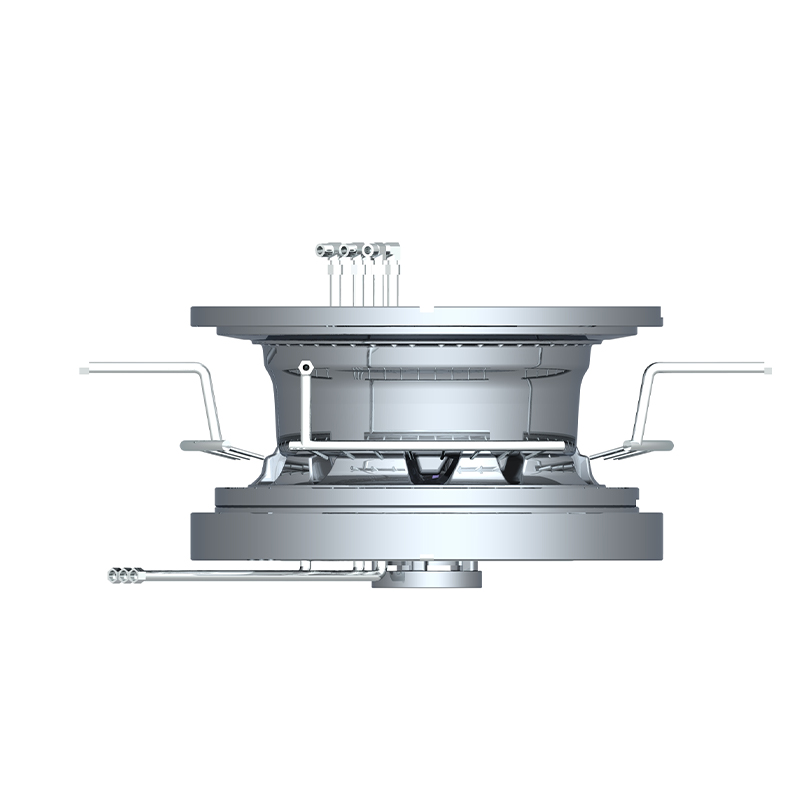

1. Casting Overview

Casting is a manufacturing process in which metal is heated to its molten state and poured into a mold to cool and form the desired shape. The casting process is widely used for large-scale production of motorcycle wheel hubs because it is cost-effective and capable of producing complex wheel designs.

1.1 What is Casting?

Casting is a traditional metalworking technique where molten metal is poured into molds and allowed to cool, solidifying into the desired shape. This process is used with various metals, particularly aluminum alloys and cast iron, and is commonly applied in the mass production of motorcycle wheel hubs.

1.2 Advantages of Casting

- Lower cost: Casting is a simpler process that requires less sophisticated equipment, making it a cost-effective option for mass production. It is ideal for motorcycle brands with a limited budget or those looking to produce large quantities of wheel hubs.

- Suitable for complex shapes: The casting process can easily produce intricate designs, such as those with different rim shapes and patterns.

- Ideal for small-batch customization: Casting offers high flexibility for small-batch or custom-made motorcycle wheel hubs.

1.3 Disadvantages of Casting

- Lower strength: Cast wheel hubs are generally more brittle and prone to cracking, especially when subjected to impacts. Their strength is much lower compared to forged hubs.

- Porosity and impurities: The cooling process during casting can cause issues like air pockets or oxidation inclusions, which negatively affect the strength and durability of the wheel hub.

- Heavier weight: Cast wheel hubs are typically heavier than forged ones, which can affect motorcycle performance, particularly for racing or lightweight motorcycle designs.

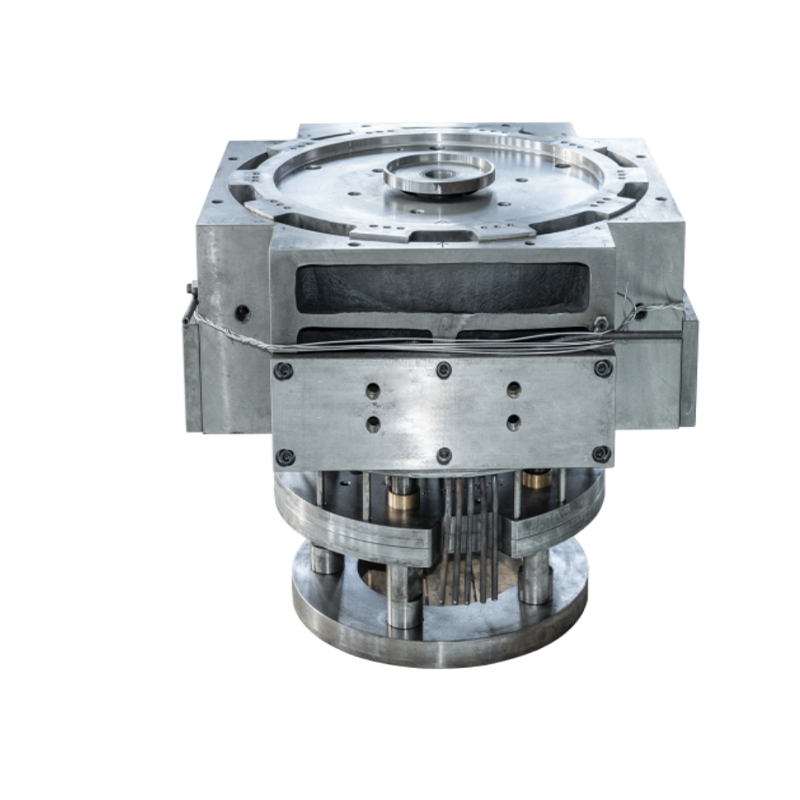

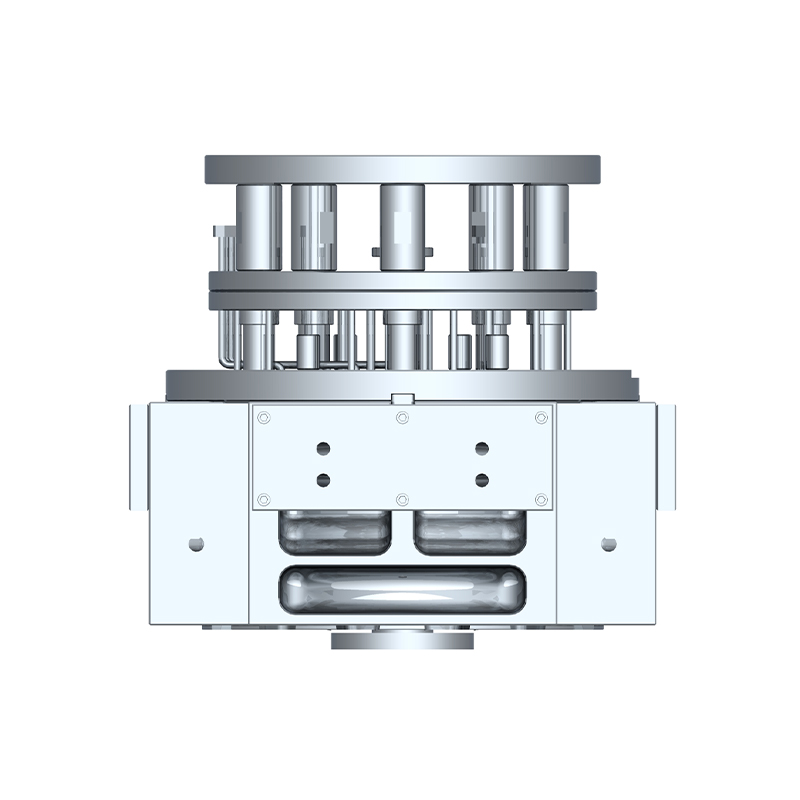

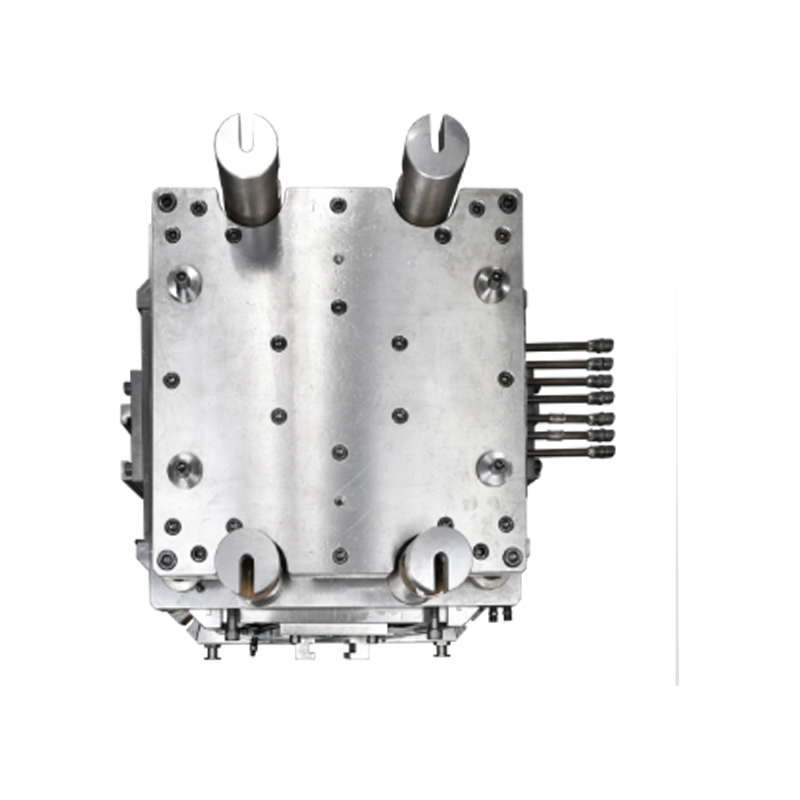

2. Forging Overview

Forging is a manufacturing process in which metal is heated to a high temperature and shaped by applying pressure. Compared to casting, forging creates a denser molecular structure within the metal, significantly increasing the strength and durability of the wheel hub.

2.1 What is Forging?

Forging is a high-strength processing method where metal is heated to a specific temperature and then mechanically compressed into a desired shape. This method is commonly used with aluminum alloys, titanium alloys, and steel, and is often applied in the manufacturing of high-performance motorcycle wheel hubs.

2.2 Advantages of Forging

- Higher strength: The forging process creates a denser molecular structure, significantly enhancing the fatigue resistance and impact strength of the wheel hub.

- Lighter weight: Forged wheel hubs are typically lighter than cast hubs, which is crucial for high-performance motorcycles, particularly in racing and sport motorcycles where weight reduction is essential.

- Better durability: Forged wheel hubs are more resistant to wear and tear over time, making them ideal for long-term, high-load applications.

2.3 Disadvantages of Forging

- Higher cost: Forging is more expensive due to the need for precision equipment and complex manufacturing processes. It may not be suitable for brands with limited budgets.

- Shape limitations: Unlike casting, forging has more restrictions on the shapes it can produce. It is better suited for simpler, high-strength designs.

- Longer production cycle: Forging typically requires a longer production cycle, which can affect mass production efficiency.

3. Casting vs. Forging: Key Differences

The table below highlights the main differences between casting and forging in the manufacturing of motorcycle wheel hubs. By comparing these factors, you can determine the most suitable method for your motorcycle’s needs.

| Feature | Casting | Forging |

|---|---|---|

| Production Cost | Low, suitable for large-scale production | High, more expensive production costs |

| Strength | Lower, more prone to cracks, suitable for low-load use | Higher, tighter metal structure, great fatigue resistance |

| Weight | Heavier, not ideal for lightweight applications | Lighter, ideal for high-performance or racing motorcycles |

| Production Cycle | Short, faster production speed | Long, longer production cycle |

| Application | Suitable for low-load, general-purpose motorcycles | Ideal for high-performance, racing, or high-load applications |

| Shape Flexibility | Flexible, able to create complex designs | Limited, best for simple, high-strength designs |

4. Which Method Suits Your Needs?

Choosing the right manufacturing method is crucial based on your motorcycle’s requirements. If you’re aiming for high performance and durability, or if your motorcycle is used in high-load applications, forging is the better option. On the other hand, if you need to produce large quantities of simple-shaped wheel hubs within a limited budget, casting might be the best choice.

4.1 If Your Need is High Performance and Lightweight

- Forging is ideal for high-performance motorcycles, especially racing and sport bikes. Forged wheels ensure greater strength and are lighter, which is crucial for handling and speed.

4.2 If Your Need is Mass Production and Budget-Friendly

- Casting is better suited for mass production. Its low cost and shorter production cycle make it an ideal choice for street bikes and entry-level motorcycles.

English

English 中文简体

中文简体