We offer molds for diverse industries, including automotive, military, and construction, enabling global competitiveness through innovation and expertise.

Injection Mold vs. Gravity Casting for Structural Parts: Cost, Precision, and Efficiency Compared

Introduction

In modern industrial production, structural parts casting is a crucial process for manufacturing high-performance components. A key question manufacturers face is: should they choose Injection Mold or Gravity Casting? These two methods differ significantly in terms of cost, precision, and production efficiency.

Overview of Structural Parts Casting Methods

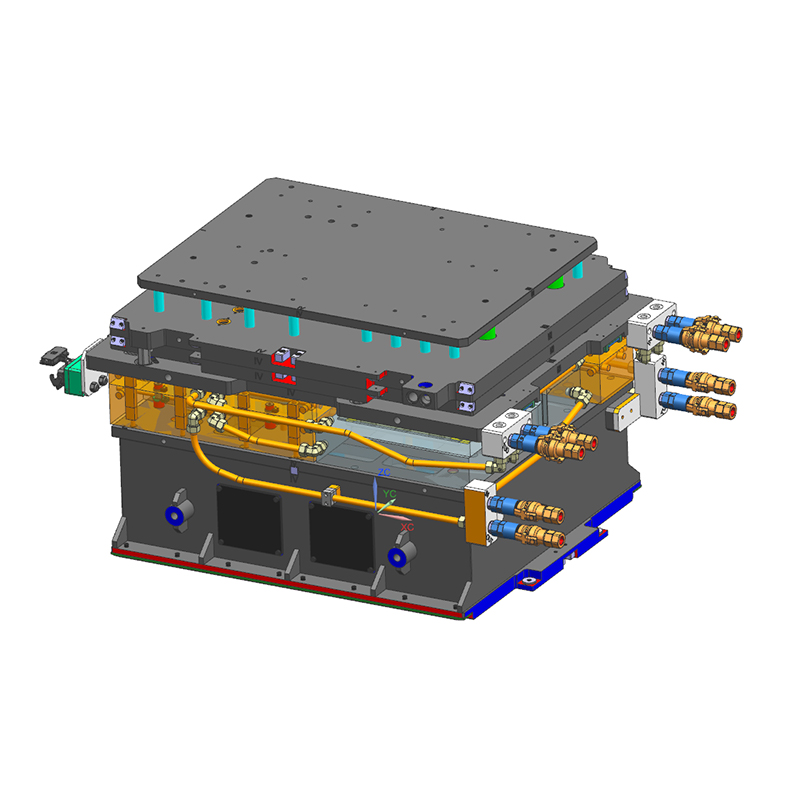

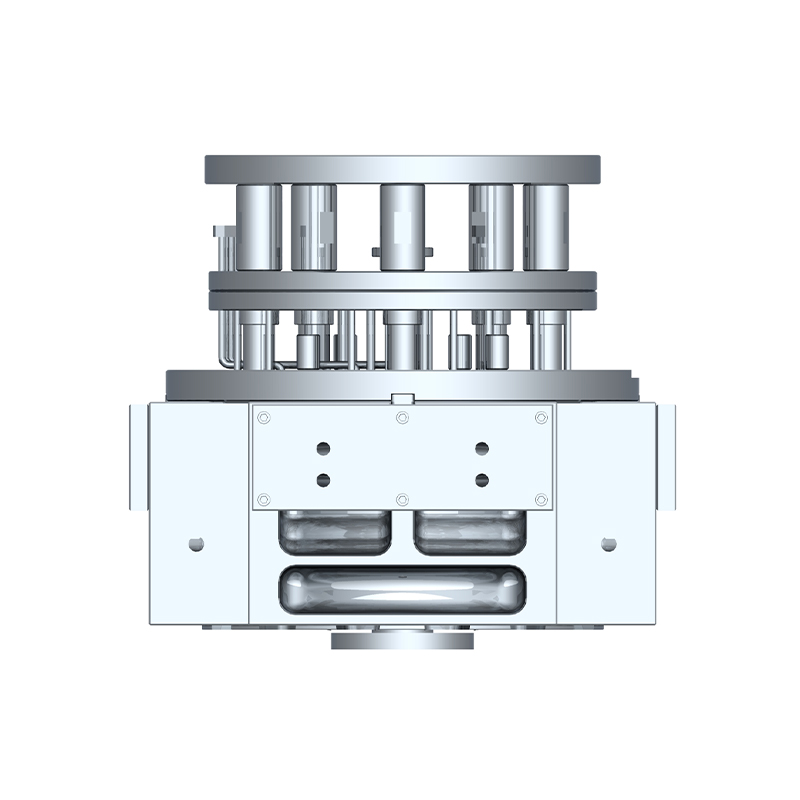

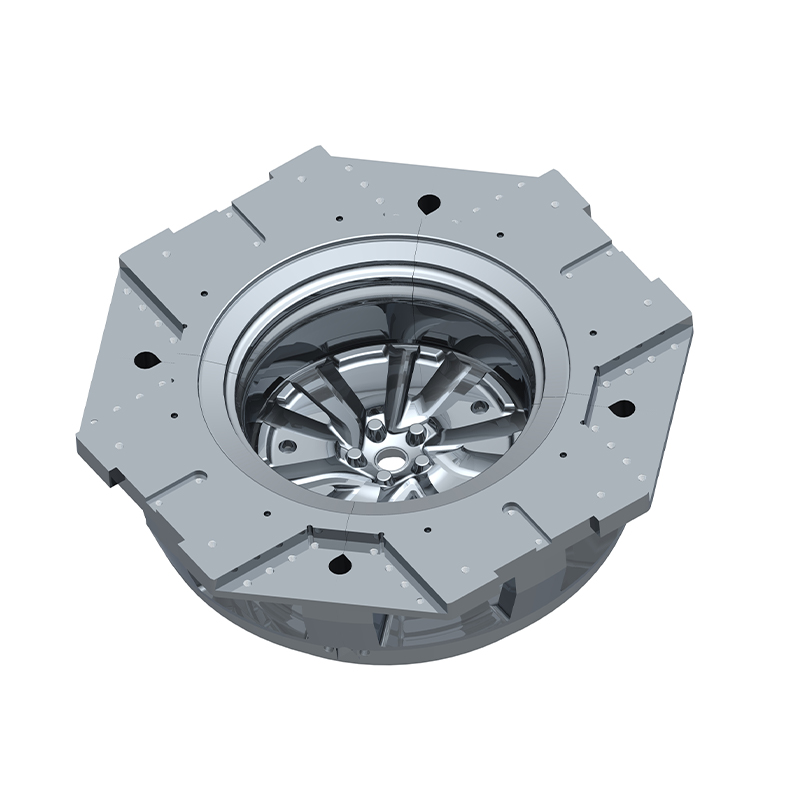

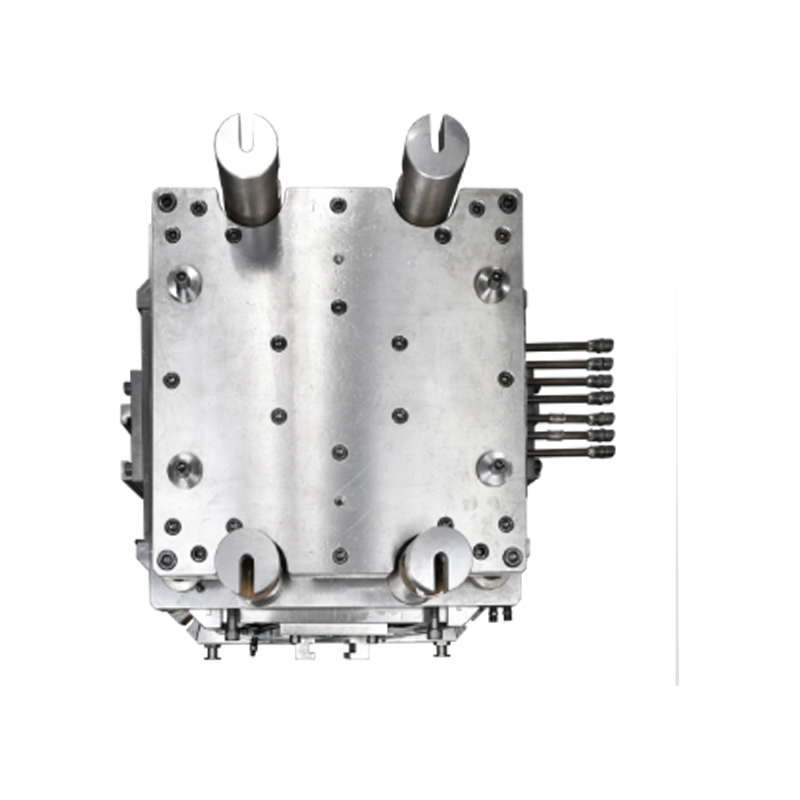

What is Injection Molding for Structural Parts?

Injection molding is a process where molten material is injected into a precise mold, cooled, and solidified to form structural parts. It is suitable for both metal and plastic materials and is especially effective for plastic components and lightweight structural parts. Injection molding offers several advantages:

Advantages

- High Precision: The molds are finely designed, allowing complex geometries and tight tolerances.

- High Repeatability: Ensures consistent part dimensions during mass production.

- Low Material Waste: Precisely controls the injected material, reducing scrap.

Limitations

- High Initial Cost: Mold manufacturing is expensive, not ideal for small batch production.

- Material Restrictions: Best suited for low-melting-point or injection-moldable materials; high-melting-point metals are limited.

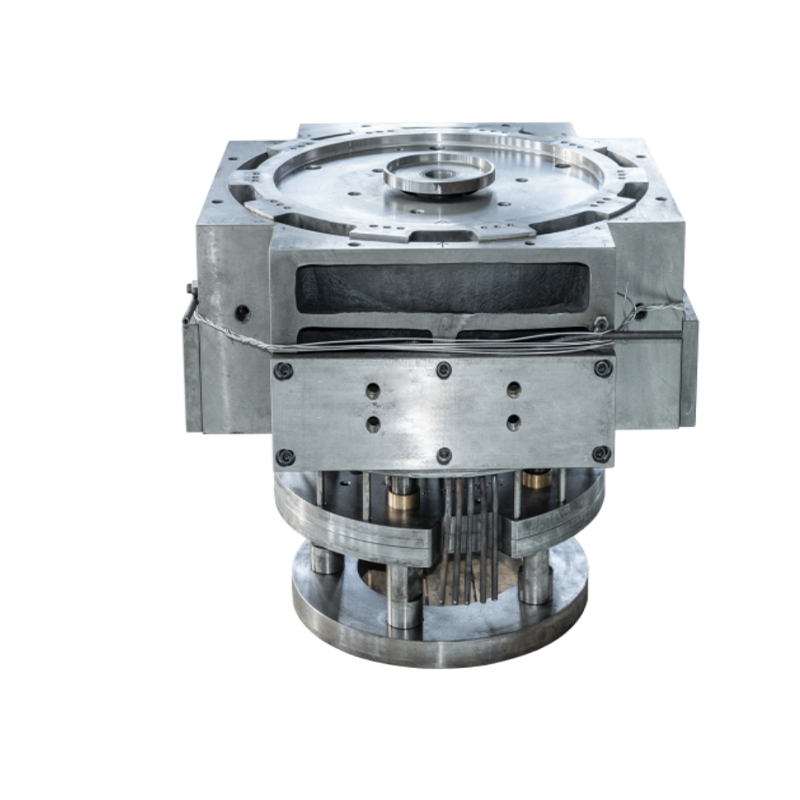

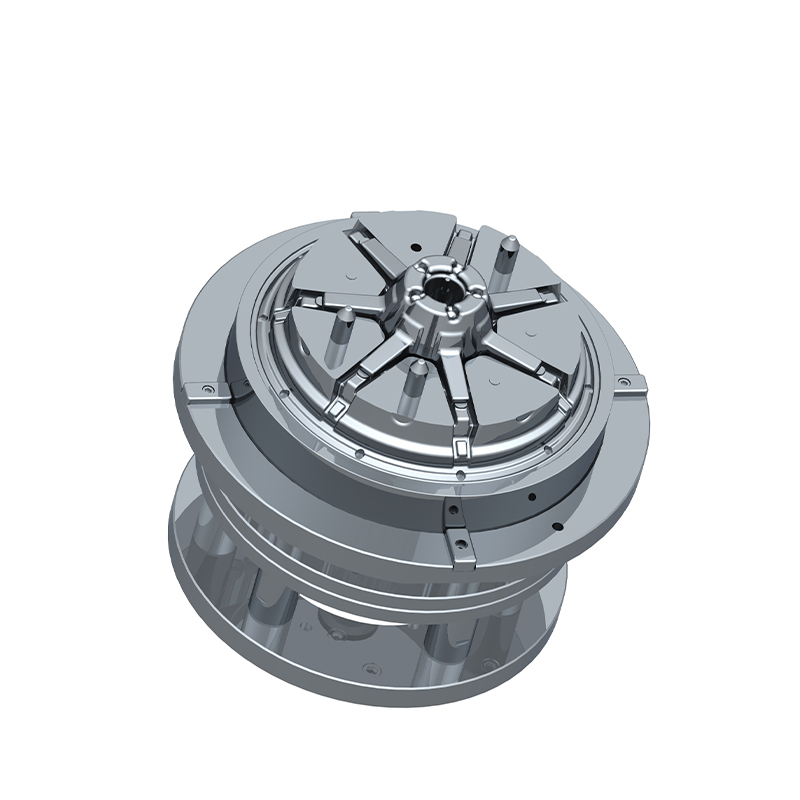

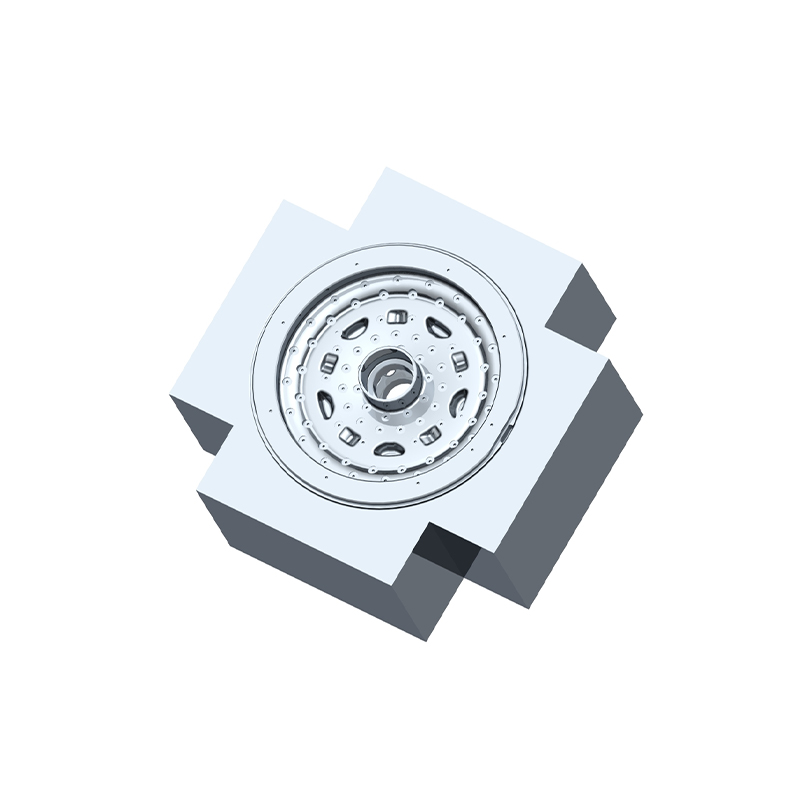

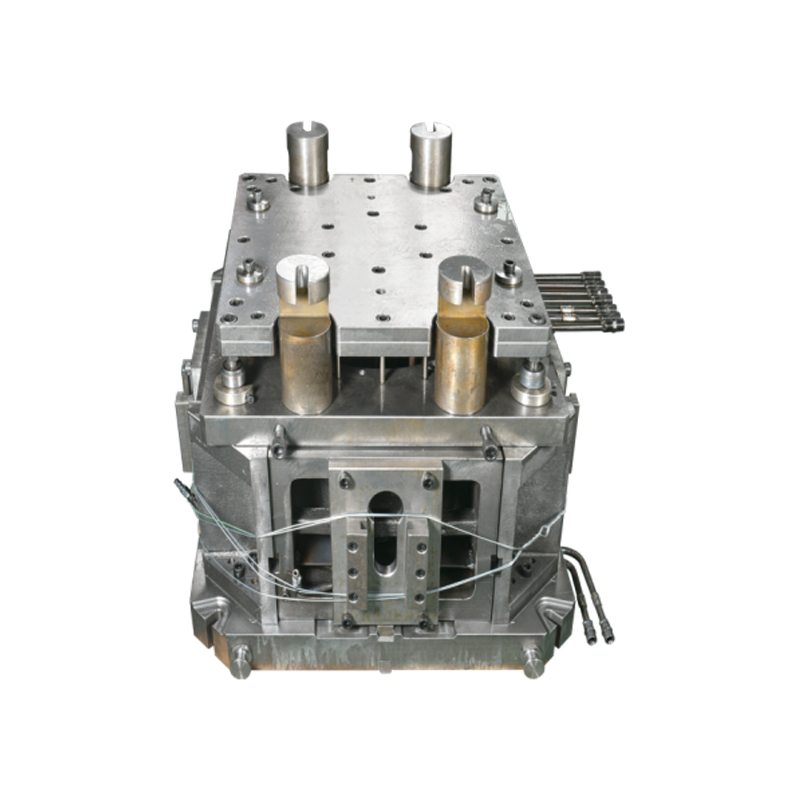

What is Gravity Casting for Structural Parts?

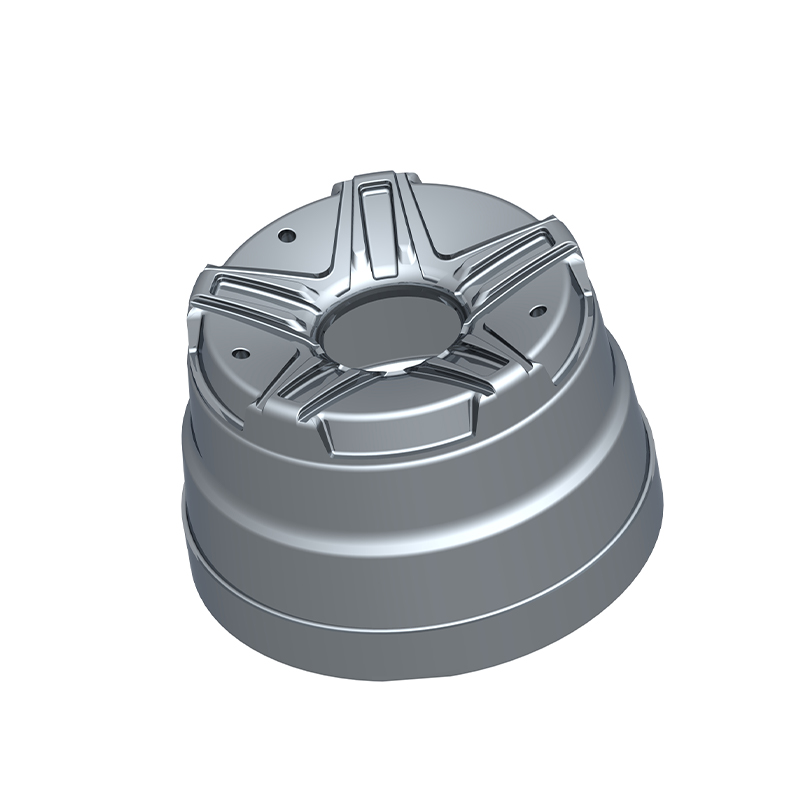

Gravity casting involves pouring molten metal into a mold and relying on gravity to fill the cavity. After cooling, the part is formed. It is widely used for aluminum, copper, steel, and other metal structural components, particularly medium to large parts.

Advantages

- Lower Mold Cost: Compared to injection molds, gravity casting molds are cheaper and suitable for small batches.

- Suitable for High-Melting-Point Metals: Can handle materials such as steel, copper, and aluminum.

- Flexibility: Mold modifications and adjustments are easier.

Limitations

- Limited Precision: Part dimensions and surface finish are generally less accurate than injection molding.

- Slower Production Speed: Longer cooling cycles result in slower single-part production.

- Defect Risk: Issues like porosity, shrinkage, and segregation can occur.

Cost Comparison

Initial Tooling Costs

The initial investment for injection molds is usually higher due to complex design, precision machining, and durable materials. In contrast, gravity casting molds are less expensive and suitable for small batches or prototype development.

Production Cost per Unit

For mass production, injection molds offer lower per-unit costs due to precision and repeatability. Gravity casting is more economical for small batches, but its unit cost can become higher than injection molds for large production runs.

Maintenance and Replacement Costs

Injection molds are durable and precise, with a long lifespan but higher maintenance costs. Gravity casting molds wear out faster but are cheaper to repair or replace.

Precision and Quality Comparison

Dimensional Accuracy

Injection molds typically achieve tolerances of ±0.05mm, whereas gravity casting usually ranges from ±0.2 to 0.5mm. Therefore, injection molds are preferred for high-precision structural parts.

Surface Finish and Defects

Parts from injection molds have smooth surfaces and low defect rates. Gravity casting parts may experience porosity, shrinkage, or rough surfaces, requiring post-processing.

Tolerance and Repeatability

Injection molds maintain high repeatability in mass production, while gravity casting is affected by temperature, material flow, and cooling conditions, leading to variable tolerances.

Efficiency and Production Speed

Cycle Time per Part

Injection molding has short cycle times, enabling fast mass production. Gravity casting requires longer cooling cycles, slowing single-part production.

Scalability for Mass Production

Injection molds are highly scalable and efficient for large-scale production. Gravity casting is better suited for small to medium batch production.

Lead Time for Tooling and Setup

Injection mold design and manufacturing take longer, resulting in longer lead times. Gravity casting molds are simpler, allowing faster production setup.

Pros and Cons Summary Table

| Criteria | Injection Mold | Gravity Casting |

|---|---|---|

| Initial Cost | High | Low |

| Unit Cost (Large Batch) | Low | High |

| Precision | High (±0.05mm) | Medium (±0.2–0.5mm) |

| Surface Finish | Smooth | Potentially rough, may need post-processing |

| Production Speed | Fast | Slow |

| Material Flexibility | Medium-Low (Low-melting-point plastics/metals) | High (Aluminum, copper, steel) |

How to Choose the Right Casting Method for Your Project

Choosing the appropriate casting method depends on your project requirements:

Batch Size Consideration

Large batch production favors injection molds, while small batches or prototypes benefit from gravity casting.

Precision Requirements

Parts requiring tight tolerances and high surface quality should prioritize injection molding.

Material Selection

High-melting-point metals or large structural components are more suitable for gravity casting.

Cost and Time Constraints

Limited budgets or projects requiring fast production may opt for gravity casting, whereas injection molds provide long-term cost efficiency and high production speed.

English

English 中文简体

中文简体